COMPILER TECO/ATL

REG. CODE

1-5302-509

MODEL N°

50778

DATE OF ISSUE

10.06.99

REVISION

00

ENDORSED

DATE

10.06.99

37

VIII

DISASSEMBLY/REASSEMBLY

Lubricate the following parts with oil before mounting: the

piston pin, the piston, the cylinder and the big-end bearing

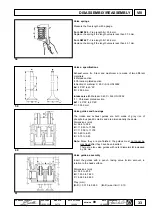

Piston, refitting

Couple the piston to the connecting-rod by inserting the pin (after it

has been lubricated) and simply pressing with the thumb.

Fit in the two circlips that hold the pin in place and make sure that

they are well housed in their seats; also see fig. 70.

Using a piston ring clamp, fit the piston into the cylinder so that the

intake valve impression (larger than the exhaust one) on the crown is

pointing towards timing system side A.

Couple the piston/connecting-rod unit to the crank shaft: consult fig.

83 for the head/connecting-rod torque value.

Piston protrusion test

Establish value A of each piston by checking in four different

diagonally opposite points of the piston crown, then make sure that

the protrusion does not exceed the following values: 0.95 to 1.27.

Series LGW 523-627 has a head gasket with a single thickness

measurement (1.65 mm). This means that the clearance can be 0.38

min. to 0.70 max..

Only remove the head gasket from its protective wrapping just

before assembly

Head gasket

The head must not be re-torqued after the running test.

Head torquing

Use a torque wrench with an angular torquing tool, see fig. 81.

Measure the length of each bolt (initial free length = 89.5 to 90.5

mm). Replace it if it exceeds 92 mm.

Lubricate with low viscosity engine oil.

81

77

78

79

80

Measured piston

protrusion

0.95 to 1.27

Gasket thickness

1.65

Clearance

0.38 min

0.38 max