36

X mm

X +- mm

6

7

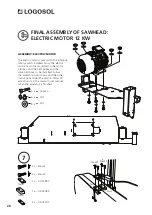

SLUTMONTERING AV SÅGHUVUDET

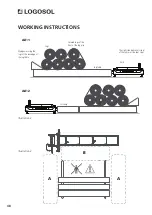

To ensure good operation of the sawmill it is

important that the blade is parallel to the rails. Place a

straightedge on the blade as close as possible to one

of the blade guide rollers. The straightedge should

rest on a tooth that is not set. Now, measure from the

lower front edge of the straightedge (measurement

point 1) vertically down to a cross bunk. Note down

the measurement. Move the sawhead forward and

measure from the rear edge of the straightedge down

to the cross bunk (measurement point B). Compare

the measurements. They should be the same at

measurement point 1 and measurement point 2.

If the measurements differ, turn the adjusting bolts

on the blade guide until the measurements are the

same at both measurment points. One method to

facilitate adjusting, is to use the value from meas-

urement point 1, compare it with the value from

measurement 2 and then, by raising or lowering the

blade guide, adjust half the difference at measure-

ment point 2. When the blade is parallel to the rails,

repeat the adjustment steps on the other blade

guide roller.

ADJUST THE PARALLELITY BETWEEN THE

BAND BLADE AND THE RAILS

Measurement

point 1

Measurement

point 2

Adjust half the difference at

measurement point 2

Measurement point 1

ORDER OF ADJUSTMENTS

Measurement point 2

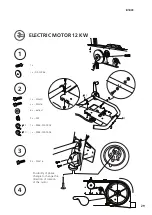

The tension of the throttle wire can be adjusted

by turning the adjusting bolt that holds the wire

coating. Turn the adjusting bolt until you get full

throttle on the engine when the throttle handle is

fully pushed in. Then secure with the counter nut.

Counter nut

TENSIONING THE THROTTLE WIRE