38

90

1

2

3

3

4

5

6

7

8

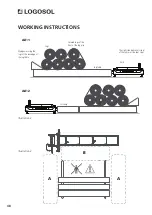

To ensure good operation of the sawmill, it is important that the cross

bunk and the log support are at right angles to each other. Adjust this by

turning the adjusting handle located at the lower part of the log support.

Check the angle with a set square.

LOG SUPPORTS

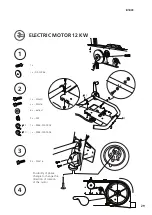

To prevent the drive belt from slipping on the

pulley, the drive belt has to be correctly tensioned.

The belt tensioner pulley assembly can be rotated

around its lower bolting. Tension the belt until

you have reached the same values at the tension

checking point as in the illustration to the right.

DRIVE BELT TENSION

Pressure: 3 kg

Belt tension

Deflection: 6 mm

Tension checking point

OTHER ADJUSTMENTS

The sawmill water tank has to be refilled before operation.

Refill through the opening in the back of the saw carriage.

The volume of the tank is 17 litres.

WATER TANK

To ensure that the scale on the sawhead crank

works correctly, it has to be calibrated. This is done

by lowering the sawhead to its lowest position and

then loosening the adjusting plate of the crank.

Now, raise the sawhead until the pointer in the

crank tube is aligned with a number on the crank

scale. It does not matter what number it is, as long

as it is aligned with the pointer. Then, tighten the

bolting. Finish the adjustment by turning the adjust-

ing bolts on the chains until the sawhead rests on

the stops in the front legs of the sawcarriage. Be

careful to adjust exactly equally much on both sides

to keep the blade parallel to the bed.

ADJUSTING THE CRANK