9

Boiler inspection and maintenance

Logano G334X – 6 720 811 237 (2014/05)

33

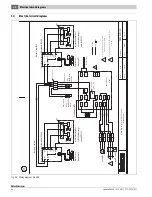

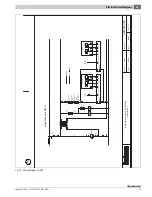

9.7

Troubleshooting the G334X

Required material:

• Circuit diagrams (

page 36)

• Voltmeter 120 VAC and 24 VAC

Fig. 46 Troubleshooting the G334X

Start

Close gas valve.

S

et thermostat

(control) to require heat (flue

baffle open).

S

witch on power.

Observe ignition sparks in gap

between electrode and sensor

through sight glass.

•

Check electrical power supply, low-voltage transformer, thermostat

(control) and wiring. Check that the vent damper (if installed) is open and

the limit switch is present.

No

No

No

Open main gas valve. Pilot flame

is burning.

•

Check that all manually operated dampers are open; check that gas

connections and pressures are correct and that ignition gas orifice are not

blocked.

•

Check electrical connection between automatic ignition and ignition timer

on the gas valve.

•

Use MV-MV/PV terminals to check 24 V alternating current at the

automatic ignition. If the voltage is correct replace gas valve, otherwise

replace automatic ignition module.

No

S

ystem operates until the heat

requirement ends.

•

Check ignition wiring and ground for continuity. Note: If the ground is

weak or faulty, the system may switch off at random, even if the heating

system operates correctly when checked.

•

Check that the pilot flame surrounds the electrode and burns evenly with

a bluish flame. If OK replace electrode.

•

If everything is OK replace automatic ignition module.

No

Heat requirement ended, system

switches off, vent damper

closes.

End of troubleshooting

Repeat procedure until heating system operates correctly.

•

On models with vent damper check that it operates and lmit switches are

present. If necessary, replace vent damper.

•

Check ignition wiring, ceramic insulator of ignition electrode and ignition

gap, adjust if necessary.

•

Check the ignition cable contact for signs of scorching or kinking.

•

Replace automatic ignition unit.

No

Ignition spark stops as soon as

pilot flame burns.

•

Check ignition wiring and ground for continuity.

•

Check ignition electrode.

•

Check electrical connections between ignition electrode and automatic

ignition.

•

Check whether the ceramic insulator in the ignition electrode is broken.

•

Check that the pilot flame surrounds the electrode and burns steadily with

a bluish flame.

•

Adjust pilot flame.

•

If this does not correct the fault, replace the automatic ignition unit

module.

No

Main burner ignites.

•

Use MV-MV/PV terminals to check 24 V alternating current, closed

current circuit at the automatic ignition. If there is no voltage, replace

automatic ignition.

•

Check electrical connection between automatic ignition module and gas

valve. If OK, replace gas valve.

•

Check operation of thermostat (control).

•

Disconnect 24-V connection to gas valve. If gas valve closes, check

thermostat and connection line again.

•

If the gas valve does not close, replace gas valve.

Содержание G334X

Страница 38: ...10 Logano G334X 6 720 811 237 2014 05 38 Notes ...

Страница 39: ...10 Logano G334X 6 720 811 237 2014 05 39 Notes ...

Страница 40: ......