a. Remove the plug from the receptacle prior to touching,

servicing or repairing the pump.

b. To minimize possible fatal electrical shock hazard, use

extreme care when changing fuses. Do not stand in water

while changing fuses or insert your finger into the fuse

socket.

4. Do not operate the pump in a dry basin. This will cause the

pump to become extremely hot, causing burns if touched

and/or damage to the pump.

5. Do not oil the motor. The pump housing is sealed. A high

grade dielectric oil devoid of water has been put into the motor

housing at the factory. Use of other oil could cause serious

electric shock and/or permanent damage to the pump.

6. This pump’s motor housing is filled with a dielectric oil for motor

heat transfer and lifetime lubrication of the bearings. This oil is

non-toxic to aquatic life. However, suffocation can occur if oil is

left on the water surface. If oil escapes the motor housing, it can

be removed from the surface quickly by placing newspapers

on the water surface to soak up the oil.

7. In any installations where property damage and/or personal

injury might result from an inoperative or leaking pump due to

power outages, discharge line blockage, or any other reason, a

backup system(s) and/or alarm should be used.

INSTALLATION

Install the pump in a suitable gas-tight basin that is at least 18” in

diameter and 24” deep.

Pumps features a 1-1/2” female NPT discharge.

Pump can be installed with ABS, PVC, polyethylene or galvanized

steel pipe. Proper adapters are required to connect plastic pipe

to pump.

Place the pump on a hard level surface. Never place pump directly

on clay, earth or gravel surfaces.

Use a check valve in the discharge line to prevent back flow of

liquid into the basin. The check valve should be a free-flow valve

that will easily pass solids.

CAUTION:

For best performance when handling solids, install the

check valve in a horizontal position or at an angle or no more than

45°. Do not install the check valve in a vertical position as solids

may settle in the valve and prevent opening on start-up.

When a check valve is used, drill a relief hole (1/8” or 3/16” diameter)

in the discharge pipe. This hole should be located below the floor

line between the pump discharge and the check valve. Unless such

a relief hole is provided, the pump could air lock and will not pump

water, even though it will run.

OPERATION

TESTING PUMP OPERATION

RFS SERIES SEWAGE EJECTOR PUMPS:

1. These pumps are equipped with a remote float switch.

2. These pumps are installed in a basin with a sealed cover, so

switch operation cannot be observed. The sump cover usually

will have a spare hole that is plugged with a rubber plug. This

plug can be removed and switch operation can be observed.

3. Plug power cord and remote float switch power cord into a

grounded receptacle with voltage consistent with pump voltage

as indicated on pump nameplate.

4. Run water into basin until pump starts.

5. Be sure gate valve in discharge line is open.

6. Allow pump to operate through several on-off cycles.

MANUAL SEWAGE EJECTOR PUMPS:

The power cord for these pumps can be plugged directly into a

properly grounded receptacle with voltage consistent with pump

nameplate for continuous pump operation.

CAUTION:

This type of operation should be used only for emer-

gency use or when a large volume of water is to be pumped. Do

not allow the pump to run dry; this may damage the pump and

void the warranty.

MAINTENANCE

If pump does not operate properly, consult the troubleshooting

chart. If trouble cannot be located with the steps shown, consult

your pump dealer or take pump to a Little Giant authorized

service center.

CAUTION:

When working on pump or switch, always unplug

pump power cord in addition to removing fuse or shutting off circuit

breaker before working on pump.

CLEANING IMPELLER AND VOLUTE

1. Remove screws that hold volute to motor housing.

2. Remove volute and clean impeller and volute passage. Do not

use strong solvents on impeller.

3. Be sure impeller turns freely after cleaning.

4.

CAUTION:

DO NOT REMOVE IMPELLER. REMOVAL OF

IMPELLER REQUIRES SPECIAL TOOLS AND IS TO BE DONE

ONLY BY AN AUTHORIZED SERVICE CENTER.

DO NOT REMOVE MOTOR HOUSING COVER. WARRANTY IS

VOID IF MOTOR HOUSING COVER, IMPELLER OR SEALS HAVE

BEEN REMOVED.

ANY REPAIR ON MOTOR MUST BE DONE BY AN AUTHORIZED

LITTLE GIANT SERVICE CENTER.

WIRING

Check local electrical and building codes before installation. The

installation must be in accordance with their regulations as well as

the most recent National Electrical Code (NEC).

To conform to the National Electrical Code all pumps must be wired

with 14 AWG or larger wire. For runs to 250', 14 AWG wire is suffi-

cient. For longer runs, consult a qualified electrician or the factory.

Pump should be connected or wired to its own circuit with no

other outlets or equipment in the circuit line.Fuses and circuit

breaker should be of ample capacity in the electrical circuit. See

chart below.

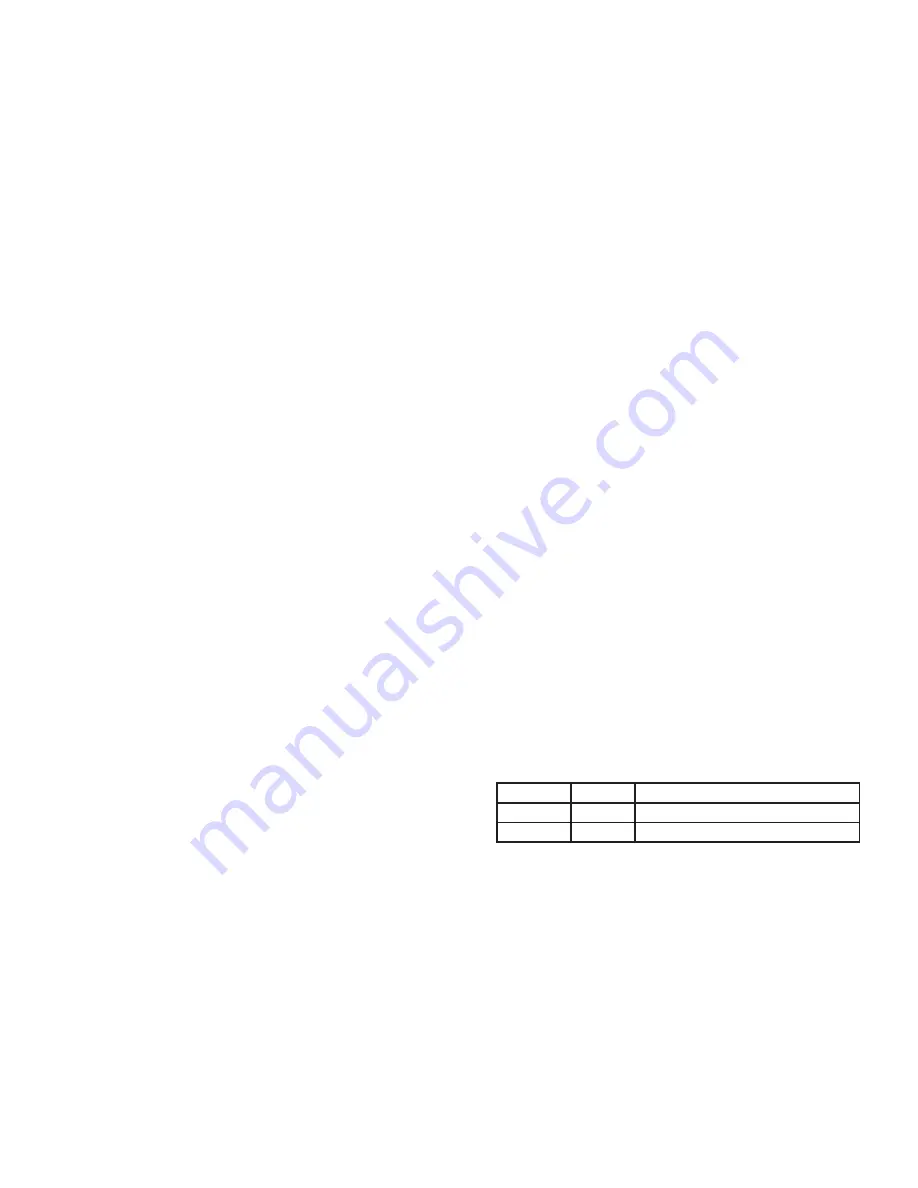

H.P.

VOLTAGE FUSE OR CIRCUIT BREAKER AMPS

1/3 or 4/10

115

20

1/3 or 4/10

230

15

REMOTE FLOAT SWITCH LEVEL CONTROL

The RFS series pumps are equipped with a remote float switch

level control. This level control is sealed in a polypropylene float

cylinder. For automatic operation, the pump must be plugged

or wired into a remote float switch. Pump will run continuously if

plugged directly into an electrical outlet.

When the level rises in the basin, the cylinder floats up with the

level. When the cylinder position is at an angle of about 45°, the

switch activates and starts the pump motor.

As the level draws down, the cylinder floats down and when it

is again at an angle of about 45°, the switch deactivates and the

pump motor stops.

NOTE:

BE CERTAIN PUMP IS SECURE IN BASIN AND CYLINDER

FLOATS UNOBSTRUCTED WITHOUT TOUCHING THE BASIN

WALLS OR PLUMBING.

3