Installation Guide Linear Motors

ENG

Page 8 / 32

P10-70-SSC / P10-70-SSC-D02

NTI AG / LinMot

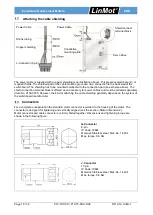

Insert the slider in the defined direction (see

Assembly step 5.).

Large magnetic attraction forces

(Observe warning notice from page 5)!

If necessary, cover obvious iron constructions

with non-magnetic material (e.g. wood).

Slider back end:

M8 thread

Slider front end:

M10 cut-in

Checking the installed direction of slider

After the installation, the front end of the slider

with M 10 thread and cut-in is located at the

opposite side of the stator from the cable exit.

Slider back end should not be used for

load mounting!

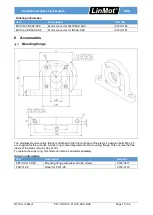

Mounting the stator

The motor is levelled and fixed to the ground using the holes in the flange foot.

The hole pattern is shown in section 9.1 "Stator Dimensions".

Mounting the payload to the slider

The load is mounted as a fixed bearing using spherical washers and conical seats (see the section 6.3).

•

To avoid shear force on slider and wear on stator, the payload has to be beared by a

linear guide.

•

Slider back end (M8 internal thread) should not be used for load mounting.