Installation Guide Linear Motors

ENG

NTI AG / LinMot

P10-70-SSC / P10-70-SSC-D02

Page 23 / 32

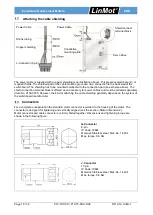

Slider back end:

M8 thread

Slider front end:

M10 cut-in

Checking the installed direction of slider

After the installation, the front end of the slider

with M 10 thread and cut-in is located at the

opposite side of the stator from the cable exit.

Slider back end should not be used for

load mounting!

Slider mounting kits

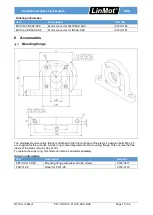

6.3.1 Fixed bearing

Slider mounting kit consists of a spring washer, a pair of spherical

washers, and a pair of conical seats. It allows the slider to be fixed

in the direction of motion. It also helps to compensate for radial and

angle offset.

Material

Spherical washer / conical seat: case hardened steel

Item

Item No.

Slider

Thread

d1

d2

d3

h

PLF01-28

(Stainless-st.)

0150-3297

28mm

M10

10.5mm

(0.41in)

12mm

(0.47in)

21mm

(0.83in)

6.5mm

(0.26in)

6.3.2 Floating bearing

Floating bearing assembly that permits radial adjustment of slider

position and permits a small amount of radial and axial movement.