English

English

7

System Connection

System Overview

The Power Wave

®

AC/DC 1000 SD CE power source is

designed to be a part of a modular welding system

typically controlled by a MAXsa™ 10 Controller or a

customer supplied Programmable Logic Controller

(PLC). Each welding arc may be driven by a single

power source or by a number of power sources

connected in parallel. The actual number of power

sources per arc will vary depending on the application.

When only one power source is required for an arc

group, it must be configured as a Master. When parallel

machines are required, one is designated as the Master

and the rest as Slaves. The synchronizing connectors for

paralleled machines are on the back of the power

source. The Master controls the AC switching for the arc

group, and the Slaves respond accordingly. See Figure

#3 below.

When employed in a multi-arc AC system the arcs must

be synchronized to each other. The Master for each arc

can be configured to follow a dedicated external

synchronization signal to determine its frequency and

balance. The Synchronizing Connectors on the back of

the Power Wave

®

AC/DC 1000 SD CE provide the

means to synchronize the AC wave shapes of up to six

different arcs to a common carrier frequency. (See

Figure #3). This frequency can range from 20 hertz to

100 hertz. It can also control the phase angle between

arcs to reduce the effects of welding related issues such

as "Arc Blow".

The arc to arc phase relationship is determined by the

timing of each arc’s "sync" signal relative to the "sync"

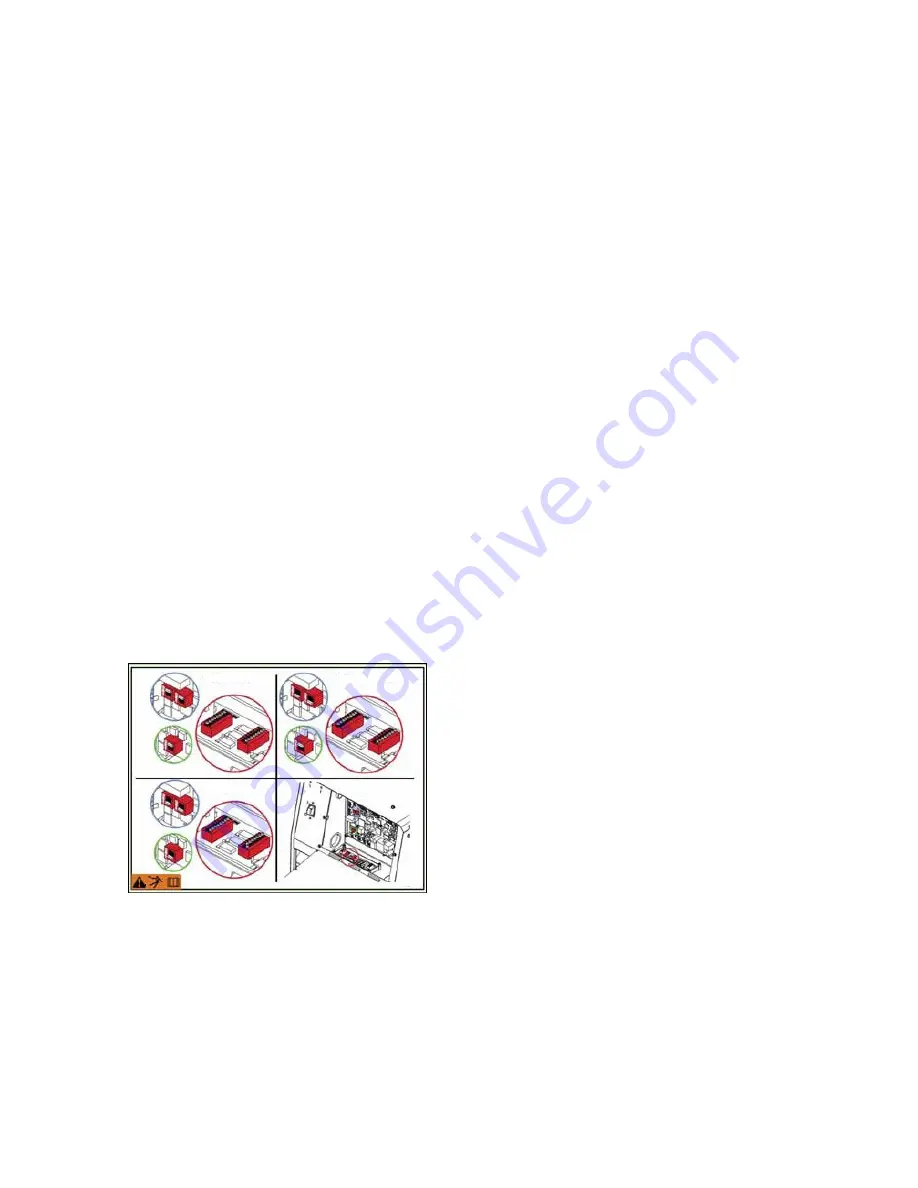

signal of ARC 1. DIP Switches on the Control PC Board

of each machine must be set to identify it as a Master

Lead, Master Trail or Slave. See Figure #2.

Figure #2: Dip Switch Settings

In a typical multi-arc system, each arc is controlled by its

own MAXsa™10 Controller. The basic characteristics of

the individual arcs such as WFS, amplitude, and offset

are set locally by each arc’s dedicated controller. The

frequency, balance, and phase shift parameters of each

arc are controlled by the MAXsa™ 10 Controller for ARC

1 (Master Lead).

NOTE:

The K2803-1 Power Wave

®

AC/DC 1000

®

SD

is backwards compatible with the K2344-2 Power

Wave

®

AC/DC 1000 in tandem or multi-arc systems.

The K2803- 1 and K2344-2 machines cannot be

connected in parallel. Paralleled machines must be of

the same type. A K1805- 1 (14 to 22 pin adapter cable)

is required to interface to the K2282-1 Systems Interface

in these setups A PLC interface is an alternate method

of control for larger systems. The PLC is typically

connected via DeviceNet directly to the Master power

source of each arc group in the system. MAXsa™ 19

Controller is still required to power the Wire Drive.

Contact your Local Lincoln Electric Representative for

more information.

The connection diagrams describe the layout of several

typical systems including Multi-Arc and Paralleled

machine set-ups. Each system also has a step by step

“Installation Checklist”.

MASTER-LEAD MASTER-TRAIL

SLAVE

Содержание K2803

Страница 11: ...English English 8 Cruiser Connection Diagram...

Страница 13: ...English English 10 Single Arc Connection Diagram...

Страница 15: ...English English 12 Tandem Arc Connection Diagram...

Страница 17: ...English English 14 Paralleling Connection Diagram...

Страница 19: ...English English 16 MAXsa 19 Connection Diagram...