B-17

OPERATION

AIR VANTAGE

®

600X-I

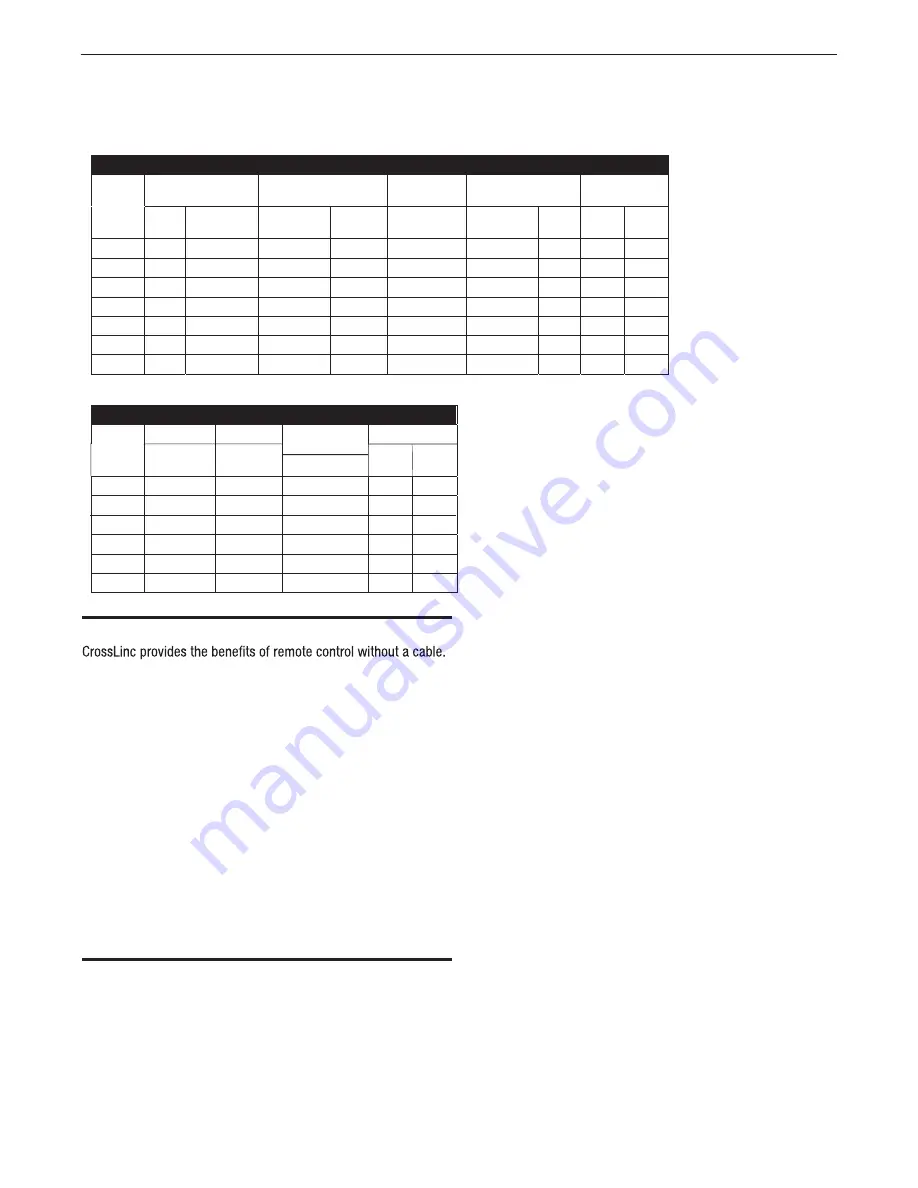

The following modes can be accessed via an ArcLink feeder:

Synergic CV Modes

Diameter

Steel

Stainless

Metal-

Cored

Flux Core

Aluminu m

CO 2

Argon

Mix

Argon

Mix

Tri-Mix

Argon Mix

Argon

Mix

CO2

4043

5356

.030

•

•

•

•

.035

•

•

•

•

.040

•

•

.045

•

•

•

•

•

•

•

3/64

•

•

.052

•

•

•

1/16

•

•

•

•

Pulse

Modes

Diameter

Steel

Stainless

Aluminu m

Argon

Mix

Argon

Mix

4043

5356

.035

•

•

.045

•

•

3/64

•

•

.052

•

1/16

•

•

•

•

TABLE B.4

•

•

•

•

•

•

•

Metal-

Cored

Argon Mix

•

•

•

•

•

040

•

.

CROSSLINC

The accessory or wire feeder talks to the power source by sending

a signal through the electrode cable.

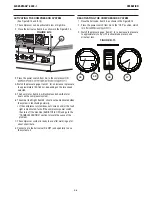

To start CrossLinc, simply connect the weld cables and sense lead

per the CrossLinc device’s instructions. Select the desired weld

mode with the machine. When weld output is ON, the CrossLinc

device will automatically link to the machine. The CrossLinc light

will be on to show active communication.

When CrossLinc is active, the remote control is disabled.

CrossLinc technology uses a communication protocol coupled in

the electrode and work cables. For best performance the total

voltage drop in the system should be kept under 10V.

CrossLinc is not compatible with High Frequency TIG. If high

frequency is in the area, the cables need to routed as far as

possible from each other. Also, follow all high frequency best

practices, including an driven earth ground.

PARALLELING

When paralleling machines in order to combine their outputs, all

units must be operated in the CC-STICK mode at the same output

settings. To achieve this, turn the WELD MODE switch to the CC-

STICK position. Operation in other modes may produce erratic

outputs, and large output imbalances between the units.