- 44 -

Chiller Water-cooled Screw

As shown below, the gear of the rotor moves from the suction to discharge side as the rotor rotates. The corre-

sponding rotor wraps the compression space and continuously reduces the volume as it moves in axis direc-

tion. Due to this, the lobe space is formed between the male and female lobe. This lobe space increases to

maximum size (Suction and seal process). As the rotor rotates, the lobe space of V shape is closed by the new

locking from the suction side. The lobe space will continue to shrink as the lobe process (Compression process)

progresses.

The reduction in lobe space occurs at the bottom side of the rotor from the discharge aspect. Volume will gradu-

ally be reduced and will be compressed in sealed condition. The peak of the gear of the rotor will be loosened

with the discharge port simultaneously and the suction gas will be discharged to the high pressure side as the

lubrication oil of the discharged gas will be separated in the oil separator. The size and shape of the discharge

port is decided by the “Internal compression ratio (Vi)” of the compressor. This ratio must have the relationship

defined by the operating pressure ratio to avoid the efficiency loss from high or low pressure axis.

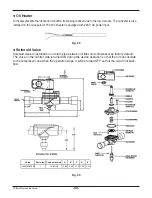

Table 13

No.

Description

No.

Description

1

Compressor case

18

Bearing fixation ring

2

Motor case

19

Disk spring

3

Oil separator

20

Bearing lock nut

4

Motor rotor assembly

21

Water rotor

5

Motor stator assembly

22

Suction bearing

6

Motor rotor washer

23

Internal/External spacer ring of suction bearing

7

Motor rotor spacer ring

24

Oil induction ring

8

Oil separator divider

25

Suction filter

9

Oil separator cartridge

26

Oil heater

10

Piston

27

Refrigerator lubrication oil

11

Piston spring

28

Suction flange

12

Piston rod

29

Discharge flange

13

Bearing cover plate

30

Cable box

14

Capacity control solenoid valve

31

Power bolt

15

Slide valve

32

Thermostat terminal

16

Slide valve key

33

Motor cable cover plate

17

Discharge bearing

34

Check valve

Содержание RCWW-1

Страница 14: ... 14 Chiller Water cooled Screw User Setting Fig 5 ...

Страница 16: ... 16 Chiller Water cooled Screw Function Setting Fig 6 ...

Страница 18: ... 18 Chiller Water cooled Screw I O Display ...

Страница 23: ... 23 Operation Maintenance Manual Running Information Fig 8 ...

Страница 77: ......