40

Single Zone V

ertical

Air Handling Unit Installation Manual

Due to our policy of continuous product innovation, some specifications may change without notification.

©LG Electronics U.S.A., Inc., Englewood Cliffs, NJ. All rights reserved. “LG” is a registered trademark of LG Corp.

REFRIGERANT PIPING CONNECTIONS

Indoor Unit Connections

Piping to Indoor Unit

Follow the steps below and refer to the illustrations on this page to connect piping to the Single Zone indoor unit. To see specific bundling

of piping and drain hose, see the Bundling and Cutting Line section. Also, refer to the Drain Hose Guidelines section on the next page for

proper drainage slope during piping procedure. Also refer to the General Piping information in Section 3.

Figure 46: VAHU Refrigerant Pipe Brazed Connections.

Liquid Pipe

Vapor Pipe

Do not braze in an enclosed location.

Do not allow the

refrigerant to leak during brazing. Always test for gas leaks before

and after brazing.

If the refrigerant combusts, it generates a toxic gas that may cause physical

injury or death.

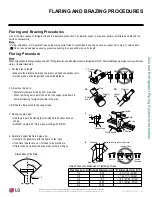

1. Joints are brazed in the field. Single Zone refrigeration system

components contain very small capillary tubes, small orifices, elec-

tronic expansion valves, oil separators, and heat exchangers that

can easily become blocked. Proper system operation depends on

the installer using best practices and utmost care while assembling

the piping system.

2. Store pipe stock in a dry place; keep stored pipe capped and

clean.

3. Purge clean all pipe sections with dry nitrogen prior to assembly.

4. Always use a non-oxidizing material for brazing.

Do not use

flux, soft solder, or anti-oxidant agents. If the proper material is not

used, oxidized film may accumulate and clog or damage the com-

pressors. Flux can harm the copper piping or refrigerant oil.

5. Use a tubing cutter,

do not use a saw to cut pipe. De-bur and

clean all cuts before assembly.

6. Brazing joints:

• Use a dry nitrogen purge operating at a minimum pressure of

three (3) psig and maintain a steady flow.

• Use a 15% silver phosphorous copper brazing alloy to avoid

overheating and produce good flow.

• Protect isolation valves, electronic expansion valves, and other

heat-sensitive control components from excessive heat with a wet

rag or heat barrier spray.

Figure 47: Refrigerant Pipe Brazing.

Regulator

Nitrogen gas

Pressure 3 psig

Auxiliary valve

Tape

Welding Point

Oxide scale

Nitroge

n

Do not block the outlet side

Содержание LV181HV4

Страница 73: ...NOTES ...