5

LESCO

squeezed against spring tension, freed from the

neutral lock position (see Neutral Latch Levers

below) and released, permits the pump to send oil

to the wheel drive motor at the rate set by the

ground speed control lever. When both traction/

steering levers are released, the mower will move

ahead in a straight line if the engine is running and

the ground speed control levers have been moved

forward out of the neutral position. Steering is

accomplished by squeezing the traction/steering

lever on the side to which the turn is to be made. If

both traction/steering levers are squeezed at the

same time, the mower will stop and then backup.

The mower can then be steered in reverse by

squeezing one of the traction/steering levers closer

to the handle than the other.

7. Neutral Latch Levers:

Pivoted inside each handle there is a neutral latch

lever which works with each of the traction/steering

levers. When either of the traction/steering levers

is squeezed and its neutral latch lever pushed

forward and engaged in the neutral lock position,

the traction/steering lever is held in a position

where its pump should not be sending any oil to

the wheel drive motor. (If this is not the case, see

Initial Adjustments 6 and 7.) The neutral latch

levers should be engaged in the neutral lock

position before starting the engine. The hardware

for the neutral latch should be "snug" to retain the

latch in the "on" or "off"positions.

8. Operator Presence Levers:

Located above the outer ends of the right and left

handles, these levers must be held down on the

handles against spring pressure when the engine

is running in order to move the ground speed

selector levers out of neutral or engage the blade

clutch. Releasing the operator presence levers

with the ground speed selector levers in any

position other than neutral or the blade clutch

engaged will shut off the engine.

9. Freewheeling (pump relief) Valves:

A “T” valve located on the side of each hydraulic

OPERATING INSTRUCTIONS

pump when opened will permit the mower to be

pushed forward or pulled in reverse without the

engine running. To override the braking force of

the hydraulic system, turn each valve counter-

clockwise two turns, move the mower as you wish

and then turn each valve clockwise two turns to

shut the valves.

10. Hour Meter and Tachometer:

Located at the lower left edge of the control panel.

When the machine is running the tachometer

displays engine rpm. When the machine is off it

displays running time.

B. Initial Adjustments.

1. Disconnect the spark plug wire.

2. Check the tire pressure. Caster Wheels should be

inflated to 25 psi. Drive Wheels should be inflated

to 15 psi. Note: New tires are overinflated in order

to properly seat the bead to the rim.

3. Check that all nuts, bolts and screws are tight.

4. Check the tension of the deck drive belts:

a.Remove the deck cover shield and engage the

blade clutch.

b.Make sure the belts clear the belt guides by

1/8" to 1/4".

c.The tension of the deck drive belts should be

adjusted so that a ten-pound pull between two

pulleys deflects each belt about 1/2". Do not

overtighten these belts. The blade clutch

should engage with only moderate force.

d.Replace the deck cover shield and disengage

the blade clutch.

5. The tension of the pump drive belt should be

adjusted so that a five-pound pull between the

engine traction drive pulley and the pump drive

pulley opposite the idler pulley deflects the belt

about 3/16".

6. The long traction/steering control rods which run

down to the pump control levers on each side of

the handle assembly should initially be adjusted so

that when the ground speed control levers are in

neutral and the traction/steering levers are released

from the neutral lock position, the mower stands

still with the engine running. If the mower starts to

creep forward or to the rear in this situation, then

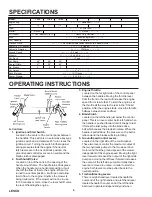

The left traction/steering lever shown

in the neutral lock position.

Содержание 708686

Страница 13: ...13 LESCO This Page Intentionally Left Blank ...

Страница 14: ...14 LESCO This Page Intentionally Left Blank ...

Страница 15: ...15 LESCO This Page Intentionally Left Blank ...