11

LESCO

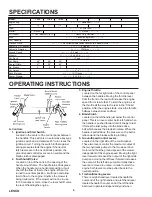

MAINTENANCE

tension to new PTO belt. If used, remove

breaker bar from idler arm.

5. Replace center mower deck cover and secure

it in place with two large wing nuts.

NOTE: Ensure that the center mower deck cover

is replaced and secured with the two large wing

nuts.

REMOVING THE MOWER DECK

WARNING: Disengage the PTO, stop engine and

remove key to avoid accidental starting and injury.

WARNING: When handling the mower deck, be

careful not to cut yourself on the sharp blades.

a. Remove the center mower deck cover by first

removing the two large wing nuts.

b. Remove the PTO belt.

c. Lift one side of the mower deck.

d. Push the button in the center of the handle of

each of the two retaining pins supporting this side

of the mower deck. Remove the pins.

e. Lower this side of the mower deck until the ball

wheels rest on the surface.

f. Repeat steps 3 through 5 for the other side of the

mower deck

g. Push down on the power unit handle bar to bring

the front caster wheels to a level above the top of

the mower deck.

h. Pull the power unit rearward, free of the mower

deck.

i. Slowly reduce force on the handle bar to lower

the front caster wheels until they rest on the

surface.

5. TO CHANGE THE PUMP DRIVE BELT:

(See Figure 5.)

a. Make sure the blade clutch is disengaged.

b. Working under the engine deck, take the long

blade drive belt off of the engine pulley.

c. Loosen the locknut holding the pump drive belt

idler pulley in place and slide the pulley away

from the pump drive belt.

d. Remove the old belt and mount a new belt on

the pulleys.

e. Slide the idler pulley back onto the belt and

tighten the locknut holding it in place. The idler

pulley should be adjusted so that a five-pound

pull on the belt between the engine pulley and

the pump pulleys deflects the belt about 3/16".

f. Replace the long blade drive belt on the engine

pulley.

6 TO CHANGE A SPINDLE ASSEMBLY:

a. Make sure the blade clutch is disengaged.

b. Remove the deck cover.

c. Remove the blade.

(See paragraph 1. To Change

a Blade.)

d. Remove the blade drive belts. (See

paragraph 3.

To Change the Blade Drive Belts.)

e. Remove the two bolts which hold the pulley

bushing tight in the spindle pulley and thread the

bolts into the other two holes in the bushing.

f. Alternately turn each bolt 1/2 turn clockwise until

the bolts force the pulley off of the

bushing.

g. Remove the bushing by tapping a large screw

driver into the slot in the side of the bushing.

h. Remove the key fom the spindle.

i. Tip the mower back and block up the front of the

deck.

j. Remove the four bolts and locknuts holding the

spindle assembly to the deck.

k. Remove the spindle assembly.

Содержание 708686

Страница 13: ...13 LESCO This Page Intentionally Left Blank ...

Страница 14: ...14 LESCO This Page Intentionally Left Blank ...

Страница 15: ...15 LESCO This Page Intentionally Left Blank ...