10

LESCO

removing two large wing nuts.

b. With the mower deck positioned in front of the

power unit, visually align mower deck channels

with power unit frame tubes.

c. Push down on power unit handle bar to bring the

front caster wheels to a level above top of the

mower deck.

d. Push the power unit over the mower deck. Align

the power unit frame tubes with the mower deck

channels.

e. Slowly reduce force on the handle bar to lower

the front caster wheels until they rest on the

surface with the frame tubes inside the mower

deck channels.

f. Push the power unit forward until the rear stop

tabs of the frame contact the mower deck

channels.

INSTALLING THE MOWER DECK

WARNING: Disengage the PTO, stop engine and

remove key to avoid accidental starting and injury.

WARNING: When handling the mower deck, be

careful not to cut yourself on the sharp blades.

a. Lift one side of the mower deck to achieve the

desired cutting height.

b. Push the button in the center of the handle of

each of the retaining pins to insert the retaining

pins through the appropriate front and rear height

adjustment holes in the mower deck channel.

Select the lowest holes that allow insertion of the

pins just above the bottom inside edge of the

power unit frame U-brackets inside the brackets.

NOTE: The same height adjustment hole must

be used for both front and rear pin installation.

c. Release the mower deck.

d. Repeat the above procedure to install the other

side of the mower deck.

NOTE: The same height adjustment hole must

be used for all four pin installations.

e. Adjust the mower deck as required. Refer to

"Adjustments" in your Operator's Manual.

f. Install the PTO belt by executing the following

procedures:

1. Remove center mower deck cover by first

removing two large wing nuts.

2. Push against idler arm to release tension on

the PTO belt. For increased leverage, a 3/8-

inch square drive of a breaker bar can be

placed in the 3/8-inch hole of the idler arm.

The breaker bar handle can be pushed to

release tension on the PTO belt.

NOTE: Be sure the narrow side of the belt is in

the bottom of the pulley grooves.

3. Carefully remove old PTO belt, and replace it

with a new belt.

4. Release force on the idler arm to restore

h. Place a new short blade drive belt back on the

pulleys and tighten the idler pull rod to hold the

idler pulley tight against the belt.

i. Place a new long blade drive belt through the

belt guide and loop it around the engine pulley

and then around the two deck pulleys. The

belt’s back side should ride on the idler pulley.

j. Replace the cap screw and nut in the idler

pulley arm. Readjust and tighten the two belt

guides under the engine deck.

k. The idler pulleys should be adjusted so that

when the blade clutch is engaged, a ten-pound

pull between two pulleys deflects either belt

about 1/2". Do not overtighten these belts. The

blade clutch should engage with only moderate

force.

l. Replace the deck cover.

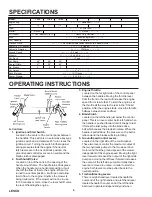

4. INSTALLATION AND REMOVAL OF MOWER

FLOAT DECK

1.

Power Unit Frame Tube

2.

Stop Tabs

3.

Mower Deck Channel

4.

Retaining Pin

5.

U-Bracket

Preparation

Place the mower in front of the power unit on a

level surface. Turn off power take-off (PTO), turn

off engine and remove key from ignition switch.

CAUTION: The mower deck and power unit must

be placed on a hard, level surface.

WARNING: Disengage the PTO, stop engine and

remove key to avoid accidental starting and injury.

WARNING: When handling the mower deck, be

careful not to cut yourself on the sharp blades.

a. Remove center mower deck cover by first

MAINTENANCE

Содержание 708686

Страница 13: ...13 LESCO This Page Intentionally Left Blank ...

Страница 14: ...14 LESCO This Page Intentionally Left Blank ...

Страница 15: ...15 LESCO This Page Intentionally Left Blank ...