6.2

The settings in the menu cannot be changed

Check in the menu whether the service mode has been activated.

6.3

Motor contactor monitoring

When the contactor is not requested by the control and nevertheless

a current is measurable on one or more phases, then the error

message “Contactor error” will appear in the display and the audible

alarm will sound.

7.0

Installation, electrical connection

7.1

Installation

The control unit

PS

MEGA

1

is placed in a control box that measures

250 x 225 x 115

mm (H x W x D) with screw fittings and air

connection). There are 4 drill holes on the switch cabinet for

mounting, which become visible when the cover is opened.

7.2

Hose attachment

As standard, a hose screw connection 8/6 mm is delivered for the

hose connection. Optionally, the switching device can be delivered

with other hose screw connections. The subsequent replacement of

the hose connection is also possible. The hose screw connection

must feature an internal thread of G1/8" towards the unit. During

replacement, it is important that a 14 mm spanner is used to secure

the corresponding nut. In any case, the threaded connection must be

used in combination with a suitable sealant.

7.3

Electrical connection power supply and pumps

The electrical connection must be performed by a qualified

electrician in accordance with the applicable VDE regulations.

HAZARD due to dangerous voltage!

Improper handling of electrical work may result in a risk of death

due to electrical voltage!

A time-lag fusing on the mains side of max.

3 x 16 A

must be

performed.

Mains connection (3~) PE , L1, L2, L3, N (image 1a in the

annex)

The connecting terminals have been designed for a max. cable cross

section of 4 mm². Attention must be paid that a right rotary field is

created. The terminals are labelled L1, L2, L3, N. The PE terminals are

implemented as a brass rail.

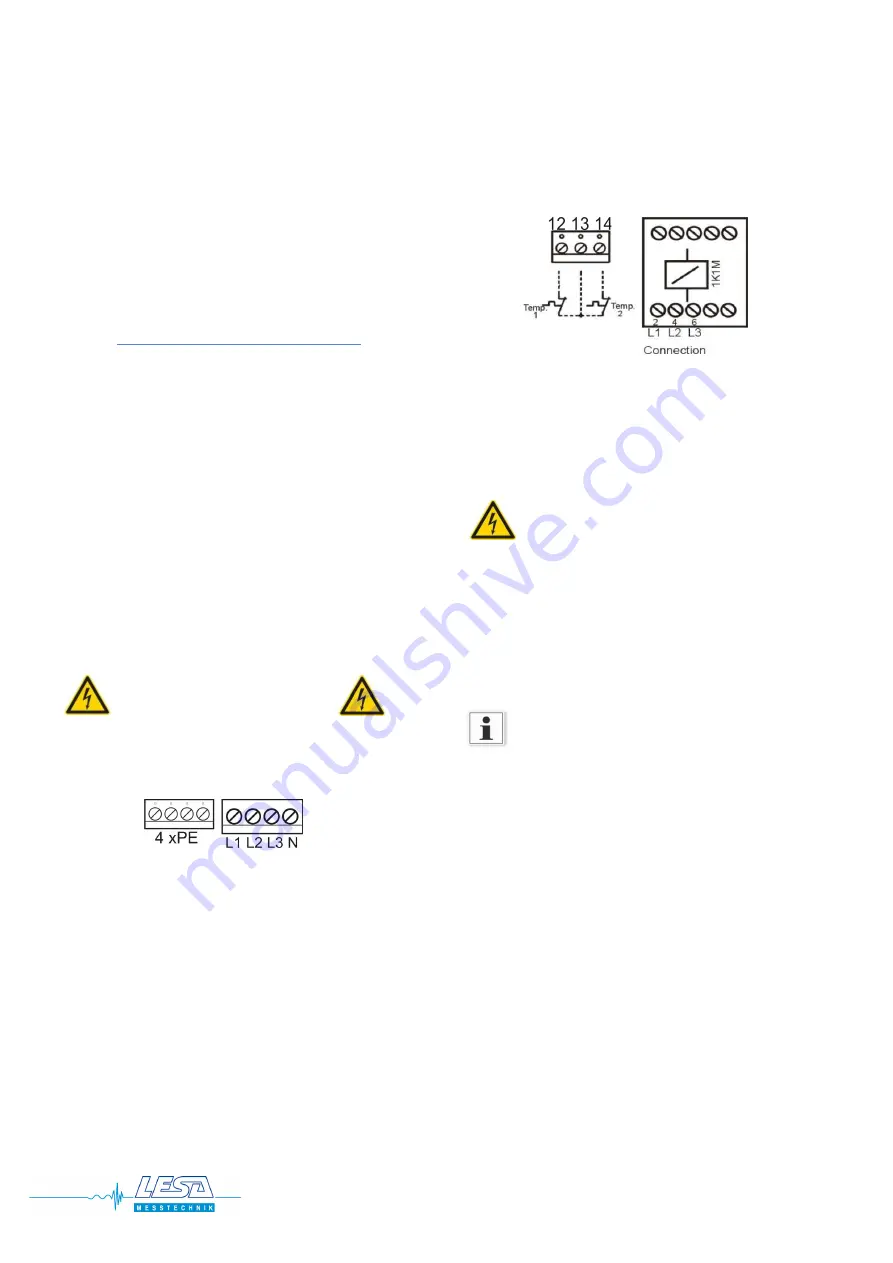

7.3.1

Connection of the pump:

The connections L1 L2 L3 of the pump are directly attached to the

motor contactor. The protective earth conductor is connected to the

remaining PE terminal. The bimetallic contact, which unlocks the

pump after it has cooled down, needs to be connected to terminal

12/13; the bimetallic contact that unlocks the pump after pressing

the “Quittung” button needs to be connected to terminal 13/14 on

the upper circuit board. (In case Temp.1 is not being connected,

thermal fault 1

needs to be deactivated in the menu).

To operate 1 ~ motors (230V AC)

a bridge between input

terminal N an L3 are necessary.

7.3.2

Power supply of the pumps (1~)

The pump is connected to contactor

T1 = L

and

T3 = N

7.3.3

Protective winding contacts

Regulator contact

Temp 1 / terminal 12/13

The pump is released automatically after cooling down.

Limiter contact

Temp 2 / terminal 13/14

The pump is only released after actuation of the acknowledge push

button.

This temperature monitoring must be used for pumps

located in the

EX area

.

When Temp. 1 is not used, then the function must be disabled in

the menu (see above chapter 5.2.7.).

When Temp. 2 is not used, then a wire jumper must be used from

terminal 13 to 14.

For pumps, in which the bimetallic contact has been switched in such

a manner that this directly interrupts the current of the pump, the

message

“Without load”

appears, when the bimetallic contact has

been triggered. The pump can only be taken into operation again

following the acknowledgement.

The inputs of the controls for the thermal errors are designed for the

evaluation of the protective winding contacts. Separate evaluation

devices must be used for motors with embedded temperature

sensors (e.g. PTC resistor) as thermal protection.

PS

MEGA

1

www.lesa.de

10