Gearbox with hollow shaft and shrink disc

NOTICE

▶

Never disassemble the new shrink disc.

▶

Thoroughly clean and degrease hollow shaft bore and machine shaft!

▶

Do not tighten clamping screws before the machine shaft has been inserted, the hollow

shaft may undergo plastic deformation.

▶

Cover the shrink disc during operation so that it is secured against contact by implementing

suitable measures (e.g. cover).

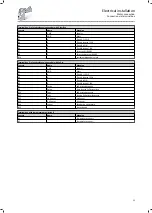

Mounting the machine shaft

1

2

1

1

Rotating cover

2

Clamping screws

1

.

Check machine shaft

-

Diameter in fit tolerance h6

-

Material yield point Re ≥= 360 MPa

-

E-module approx. 210000 MPa

-

Surface roughness R

z

≤ 15 µm

-

Concentricity (to prevent unnecessary additional forces caused by tensioning)

2

.

Remove rotating cover

(1)

from the shrink disc

3

.

Thoroughly clean and degrease hollow shaft bore and machine shaft.

4

.

Slightly loosen clamping screws (2) one after the other, do not unscrew.

5

.

Push gearbox onto machine shaft.

6

.

Slightly tighten clamping screws manually.

7

.

Tighten clamping screws (2) one after the other (approx. 5) in several passes, with rising

torque, evenly until the indicated screw-tightening torque is reached at all screws.

8

.

Pull the co-rotating cover (1) over the shrink disc.

Mechanical installation

Mounting

25

Содержание g500-S

Страница 2: ......

Страница 23: ...Dimensions Dimensions are contained in the configuration document Mechanical installation Dimensions 23...

Страница 47: ...Template Dipsticks for G50BS122 100 mm 50 10 0 M1 M3 M4 M6 M2 M5 Maintenance Maintenance work 47...

Страница 48: ...Template Dipsticks for G50BS140 M1 M3 M6 M5 M2 M4 mm 100 50 10 0 Maintenance Maintenance work 48...

Страница 70: ......

Страница 71: ......