Determine correction factor

Ambient temperature

T

U

°C

≤ 40

Correction factor

k

TU

1

Installation height amsl

≤ 1000 m

≤ 2000 m

≤ 3000 m

≤ 4000 m

Correction factor

k

H

k

H

k

H

k

H

1

0.95

.90

.85

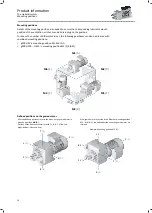

Determine product on the basis of the forces

Transmission element

Gear wheels

Sprockets

Toothed belt pulleys

Narrow V-belt

(depending on the

pretension)

(depending on the

pretension)

Additional radial force factor f

Z

≥ 17 teeth: 1.0

≥ 20 teeth: 1.0

With belt tightener: 2.0 –

2.5

1.5 – 2.0

< 17 teeth: 1.15

< 20 teeth: 1.25

Without belt tightener: 2.5

– 3.0

< 13 teeth: 1.4

Calculation

Check

Radial force

F

rad

N

´

=

´

L,max

z

rad

M

f

F

2000

dw

F

rad

≤ f

W

x F

rad,max

Axial force

F

ax

N

F

ax

≤ F

rad,max

x 0.5

dw

Effective diameter of transmission element in mm

f

W

Additional load factor

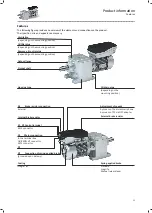

Radial forces and axial forces

Calculate output torque

Calculation

Necessary output torque

M

2

N

m

³

´

L,max

2

H

TU

M

M

k

k

Calculate intensity

Calculation

Intensity

F

I

+

+ +

=

£

+ +

L

M

B

Z

2

I

M

B

Z

J

J

J

J

i

F

1.25

J

J

J

i

Ratio of gearbox

J

B

Moment of inertia of brake

J

L

Moment of inertia of the load

J

Z

Additional moment of inertia (handwheel, 2nd shaft end ...)

J

M

Moment of inertia of motor

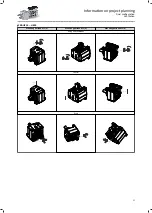

Determine the product on the basis of the data obtained from the selection tables

Selection table

Check

Output speed n

2

rpm

n

L,max

≈ n

2

Output torque M

2

Nm

M

L,max

≤ M

2

Information on project planning

Drive dimensioning

22

Содержание g500-H

Страница 1: ...Mains operated geared motors g500 H helical geared motor Smart Motor m300 E Project planning EN...

Страница 2: ......

Страница 114: ......

Страница 115: ......

Страница 116: ...11 2021 2 0 www Lenze com...