506305-01

Page 24 of 36

Issue 0938

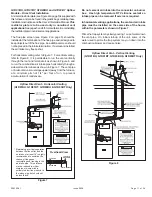

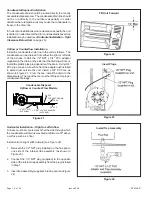

Electrical Wiring

The furnace must be grounded and wired in accordance

with local codes or, in the absence of local codes, with the

National Electrical Code ANSI/NFPA No. 70 (latest edition)

and/or CSA C22.1 Electrical Code (latest edition) if an

external electrical source is utilized.

In all instances, other than wiring for the thermostat, the

wiring to be done and any replacement of wire shall conform

with the temperature limitation for Type T wire –63°F (35°C)

rise.

Connect a sufficiently sized wire with ground to the furnace’s

line voltage connections and ground lug. Refer to the furnace

rating plate for electrical characteristics to be used in sizing

field supply wiring and over-current protection.

The line voltage supply should be routed through a readily

accessible disconnect located within sight of the furnace.

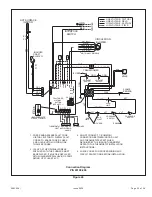

A junction box on the furnace side panel is provided for line

voltage connections. Refer to the furnace wiring diagram

for specific connection information.

Proper polarity of the supply connections (“HOT” and

“NEUTRAL”) must be observed to ensure that safety

controls provide the protection intended.

A connection to the ground lug and actual earth ground

(typically a ground stake or buried steel pipe) must be

maintained for proper operation.

Filters

Filters are not supplied with G1D93BC series furnaces.

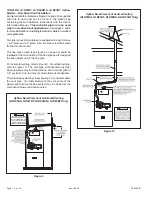

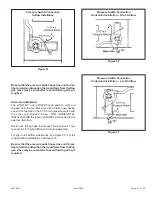

G1D91BU, G1D91BT, G1D93BT AND G1D93BU Upflow

Models

A filter rack and cleanable 16” x 25” x 1/2” filter are supplied

with the furnace. (Models designed for more than 1600 CFM

nominal air delivery include two of each.) The filter rack is

to be installed between the return air duct and the side of

the furnace. Refer to Figure 36 and the following instructions

to install the filter rack:

1. Using the corner embossments as a guide, mark and

cut a full-size opening in the side panel(s).

Risk of electrical shock. Disconnect electrical power at

the circuit breaker or service panel before making

electrical connections. Failure to disconnect power

supplies can result in property damage, personal injury,

or death.

WARNING

2. Using the filter rack as a template, mark and drill four

7/64” diameter screw holes in the side panel(s).

3. With the filter access opening toward the front of the

furnace, use sheet metal screws to fasten the rack(s) to

the side panel(s).

The filter slides in the rack from the front of the unit. Install

the filter(s) with the mesh side towards furnace.

Single side filter frame kit AFILTHA7 is available for single

side return air connection in installations requiring more than

1600 CFM nominal air delivery. Bottom return filter kit

AFILT529 is also available from the manufacturer.

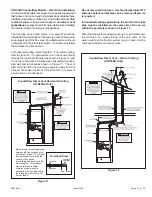

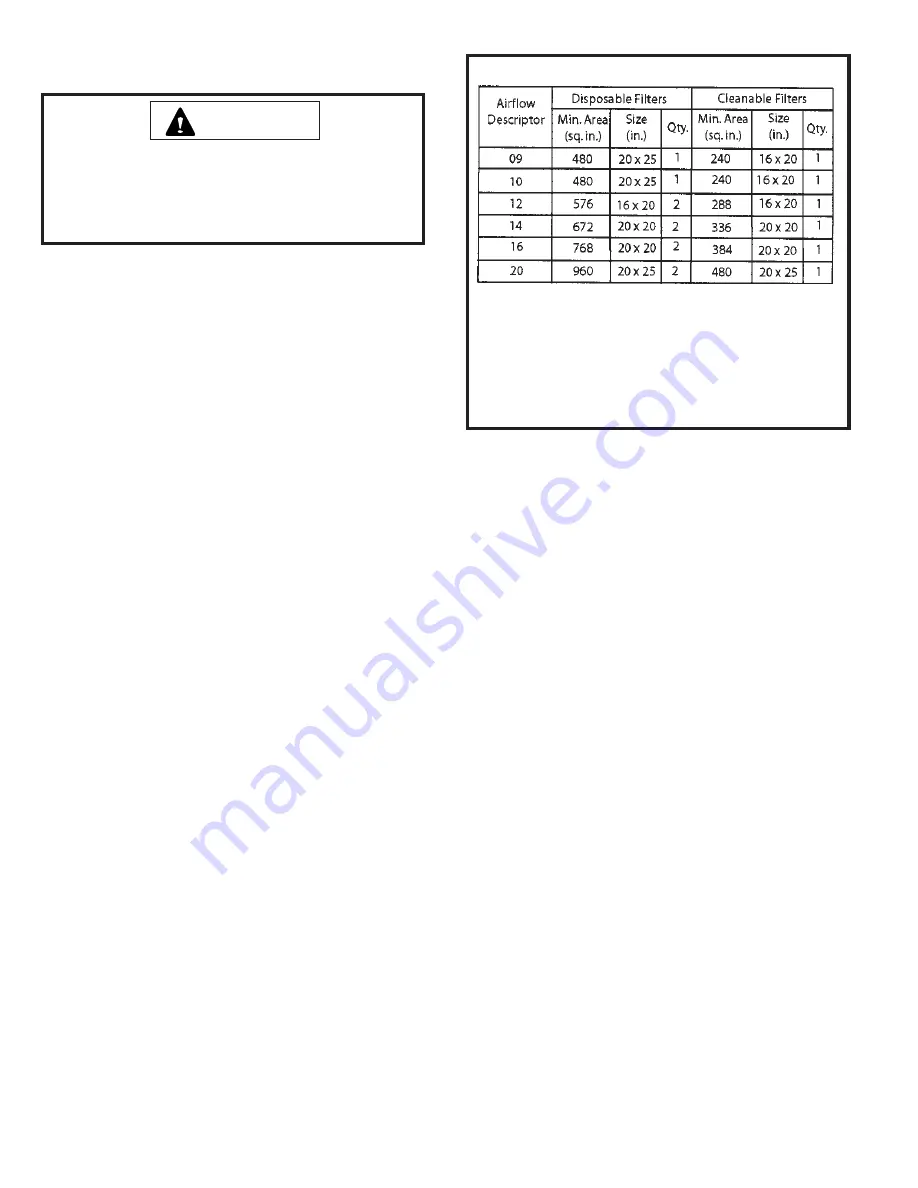

GID93BC Counterflow Models

Filters are not supplied with these furnaces, however, filters

must be used. It is the installer’s responsibility to install

properly sized filters in accordance with Table 3.

Other filter accessories are also available from the

manufacturer including a full line of indoor air quality

products. For information on these products, contact the

local distributor.

Table 3

Minimum Filter Requirements

1.

The Airflow Descriptor is the two digits following the “D” in the

model number.

2.

Areas and dimensions shown for cleanable filters are based

on filters rated at 600 feet per minute face velocity.

3.

Typical filter sizes are shown; however, any combination of filters

whose area equals or exceeds the minimum area shown is

satisfactory.