506305-01

Page 22 of 36

Issue 0938

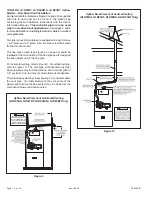

Outlet Duct

For installations not equipped with a cooling coil, a removable

access panel must be provided in the outlet duct. The

opening should be accessible when the furnace is placed in

service. Smoke or reflected light may be observed inside

the casing to indicate the presence of leaks in the heat

exchanger. The cover for the opening shall be attached in

such a manner as to prevent leaks. The recommended

opening size is 6" x 14" for all sizes.

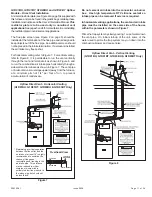

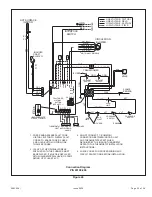

Duct Connection – G1D93BC Counterflow Models

If a unit is installed on a noncombustible floor, it may be installed

directly over the supply duct or plenum. For installations on

combustible flooring, a special base must be ordered and used.

(See the

Accessories

section on page 31 for more

information.) To install using the special base assembly, see

Figure 34 and the following instructions:

1.

Cut a hole in the floor, sized to provide 1" clearance

between all four sides of the duct and the edge of the

flooring. The four angles on the base assembly should

recess into the floor joists and the base should rest on

all four outside flanges.

2.

Construct duct connections with right angle flanges.

Circulating Air Supply

When the furnace is installed so that the supply ducts carry

air circulated by the furnace to areas outside the space

containing the furnace, the return air shall be handled by a

duct or ducts sealed to the furnace casing and terminated

outside the space containing the furnace.

A return air duct system is recommended. If the unit is

installed in a confined space or closet, a return connection

must be run, full size, to a location outside the closet. The

air duct in the closet must be tight to prevent any entrance

of air from the closet into the circulating air.

If there is no complete return air duct system, the return air

connection must be sealed to the furnace casing and run,

full size, to a location outside the utility room or space housing

the furnace to prevent a negative pressure on the venting

system.

3.

Drop the duct connections through the top of the base

assembly with the right angle flanges in good contact

with the glass tape on top of the base assembly.

4.

Carefully position the furnace over the right angle duct

flanges.

Gas Supply and Piping

Refer to the furnace rating plate to make sure the furnace is

equipped to burn the gas supplied (natural or propane).

Any conversion of a natural gas unit to propane gas must

be done by qualified personnel using a conversion kit

available from the manufacturer, following the instructions

in the conversion kit. If done improperly, overfiring of the

burners and improper burner operation can result. This

can create carbon monoxide which could cause

asphyxiation.

WARNING

When an air conditioning unit is used in conjunction with

the furnace, the evaporator coil must be installed in the

discharge (supply) air. Do not install an evaporator coil

in the return air; excessive condensation will occur within

the furnace.

CAUTION

Combustible Floor Installation

(G1D93BC Counterflow Models Only)

Figure 34

1

"

Combustible

Flooring

Woven

Glass Tape

Base

Assembly

Duct

Furnace