Page 19

Table 7

Blower Performance

(0 through 0.50 in. w.g. External Static Pressure Range)

ADJUST"

Jumper

Setting

HEAT" Jumper Speed Position [kBtuh heat input]

COOL" Jumper Speed Position

A

B

C

D

A

B

C

D

cfm

L/s

cfm

L/s

cfm

L/s

cfm

L/s

cfm

L/s

cfm

L/s

cfm

L/s

cfm

L/s

Model SLO183BV101/114V42 Units

Do not use

[−114]

Do not use

[−101]

(+)

N/A

N/A

Same as

NORM

N/A

N/A

Same as

NORM

1610

760

1380

650

1150

540

920

435

NORM

N/A

N/A

1450

684

N/A

N/A

1200

565

1400

660

1200

565

1000

470

800

380

(–)

N/A

N/A

Same as

NORM

N/A

N/A

Same as

NORM

1190

560

1020

480

850

400

680

320

Model SLO183BV135/150V60 Units

Do not use

[−150]

Do not use

[−135]

(+)

N/A

N/A

Same as

NORM

N/A

N/A

Same as

NORM

2300

1085

2070

975

1840

870

1380

650

NORM

N/A

N/A

1730

816

N/A

N/A

1450

684

2000

945

1800

850

1600

755

1200

565

(–)

N/A

N/A

Same as

NORM

N/A

N/A

Same as

NORM

1700

800

1530

720

1360

640

1020

480

NOTE − Continuous Fan air volume is 50% of COOL speed.

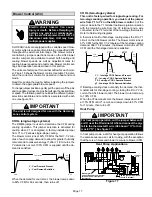

Blower Control (A54)

Figure 18

16−PIN PLUG

(BOARD TO MOTOR)

CFM LED

ADJUST

SELECTOR PINS

(Setting affects

cooling only)

HEATING SPEED

SELECTOR PINS (SEE

TABLE)

COOLING SPEED

SELECTOR PINS

NOTE − The JW1 resistor

must be cut to activate the

HUM terminal.

SLO183B3/4−12

0

SLO183B3/4−10

5

SLO183B5−135

SLO183B5−150

HEAT SPEED PINS

(JUMPERS)

NOTE − Do NOT move

heat speed jumpers from

factory settings.

Start−Up & Adjustment

Before starting unit, make sure the oil tank is adequately

filled with clean No. 1 or No. 2 furnace oil.

NOTE − Water, rust or other contaminants in oil supply sys-

tem will cause malfunction and failure of the internal parts

of the fuel unit.

CAUTION

Never burn garbage or paper in the heating system.

Never leave papers near or around the unit.

CAUTION

Blower access door must be in place before start-up.