Page 11

XP15 SERIES

ISOLATION GROMMETS

Locate the provided isolation grommets. Slide grommets

onto vapor and liquid lines. Insert grommets into mullion to

isolate refrigerant lines from sheet metal edges.

Brazing Line Set Connections

Use the following procedure to braze the line set to the new

outdoor unit. Figure 19 is provided as a general guide for

preparing to braze the line sets to the outdoor unit.

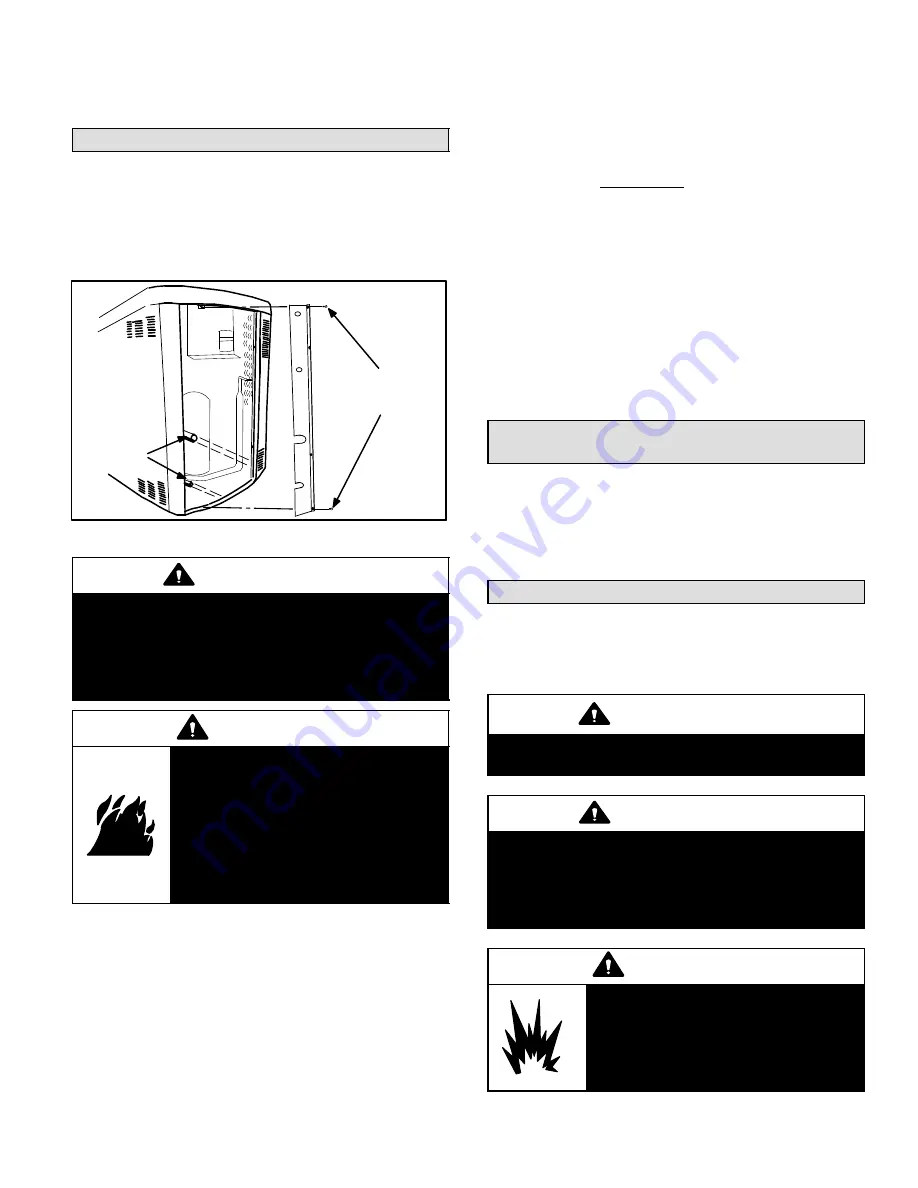

Before brazing, remove the access panel as illustrated in

figure 11; then remove the narrow piping panel to prevent

burning off the paint as illustrated in figure 20.

REMOVE TWO SCREWS

AND REMOVE PANEL

BEFORE BRAZING.

PIPING

PANEL

LINE SET

CONNECTION

POINTS.

Figure 20. Piping Panel Removal

WARNING

Polyol ester (POE) oils used with HFC−410A

refrigerant absorb moisture very quickly. It is very

important that the refrigerant system be kept

closed as much as possible. DO NOT remove line

set caps or service valve stub caps until you are

ready to make connections.

WARNING

Danger of fire. Bleeding the

refrigerant charge from only the high

side may result in the low side shell

and suction tubing being

pressurized. Application of a brazing

torch while pressurized may result in

ignition of the refrigerant and oil

mixture − check the high and low

pressures before unbrazing.

1. Cut ends of the refrigerant lines square (free from

nicks or dents). Debur the ends. The pipe must remain

round, do not pinch end of the line.

2. Remove service cap and core from both the vapor and

liquid line service ports.

3. Connect gauge low pressure side to liquid line service

valve.

4. To protect components during brazing, wrap a wet

cloth around the liquid line service valve body and

copper tube stub and use another wet cloth

underneath the valve body to protect the base paint.

Also, shield the light maroon R−410A sticker.

5. Flow regulated nitrogen (at 1 to 2 psig) through the

refrigeration gauge set into the valve stem port

connection on the liquid line service valve and out of

the valve stem port connection on the vapor service

valve. The CTXV metering device at the indoor unit

coil will allow low pressure nitrogen to flow through the

system.)

Note: Use silver alloy brazing rods with five or six percent

minimum silver alloy for copper−to−copper brazing or 45

percent silver alloy for copper−to−brass or copper−to−steel

brazing.

6. Braze the line set to the liquid line service valve. Turn

off nitrogen flow. Repeat procedure starting at

paragraph 4 for brazing the vapor line set to service

valve.

After brazing the vapor line set to the service valve,

disconnect gauge from service port, remove wrapping and

replace service port cores.

Removing Existing Refrigerant Metering

Device

Remove the existing HCFC−22 refrigerant flow control

orifice or thermal expansion valve from the indoor coil.

Existing devices are not approved for use with HFC−410A

refrigerant and may prevent proper flushing. Use a

field−provided fitting to reconnect lines. See figure 23 on

page 13 for disassembly and typical removal instructions.

Testing for Leaks

After the line set has been connected to both the indoor

and outdoor units, check the line set connections at both

the indoor and outdoor units unit for leaks. Use the

following procedure to test for leaks:

IMPORTANT

Leak detector must be capable of sensing HFC

refrigerant.

WARNING

Refrigerant can be harmful if it is inhaled.

Refrigerant must be used and recovered

responsibly.

Failure to follow this warning may result in personal

injury or death.

WARNING

When using a high pressure gas such

as dry nitrogen to pressurize a

refrigeration or air conditioning

system, use a regulator that can

control the pressure down to 1 or 2

psig (6.9 to 13.8 kPa).