Page 13

XP15 SERIES

REQUIRED EQUIPMENT

Equipment required to flush the existing line set and indoor

unit coil:

S

Two clean HCFC−22 recovery bottles,

S

Oilless recovery machine with pump-down feature,

S

Two gauge sets (one for HCFC−22; one for

HFC−410A).

LOW

PRESSURE

HIGH

PRESSURE

EXISTING

INDOOR

UNIT

GAUGE

MANIFOLD

INVERTED HCFC−22 CYLINDER

CONTAINS CLEAN HCFC−22 TO

BE USED FOR FLUSHING.

LIQUID LINE SERVICE VALVE

INLET

DISCHARGE

TANK

RETURN

CLOSED

OPENED

RECOVERY

CYLINDER

NOTE − The inverted HCFC−22 cylinder must contain at least the same

amount of refrigerant as was recovered from the existing system.

RECOVERY MACHINE

NEW

OUTDOOR

UNIT

SUCTION LINE

SERVICE VALVE

SUCTION

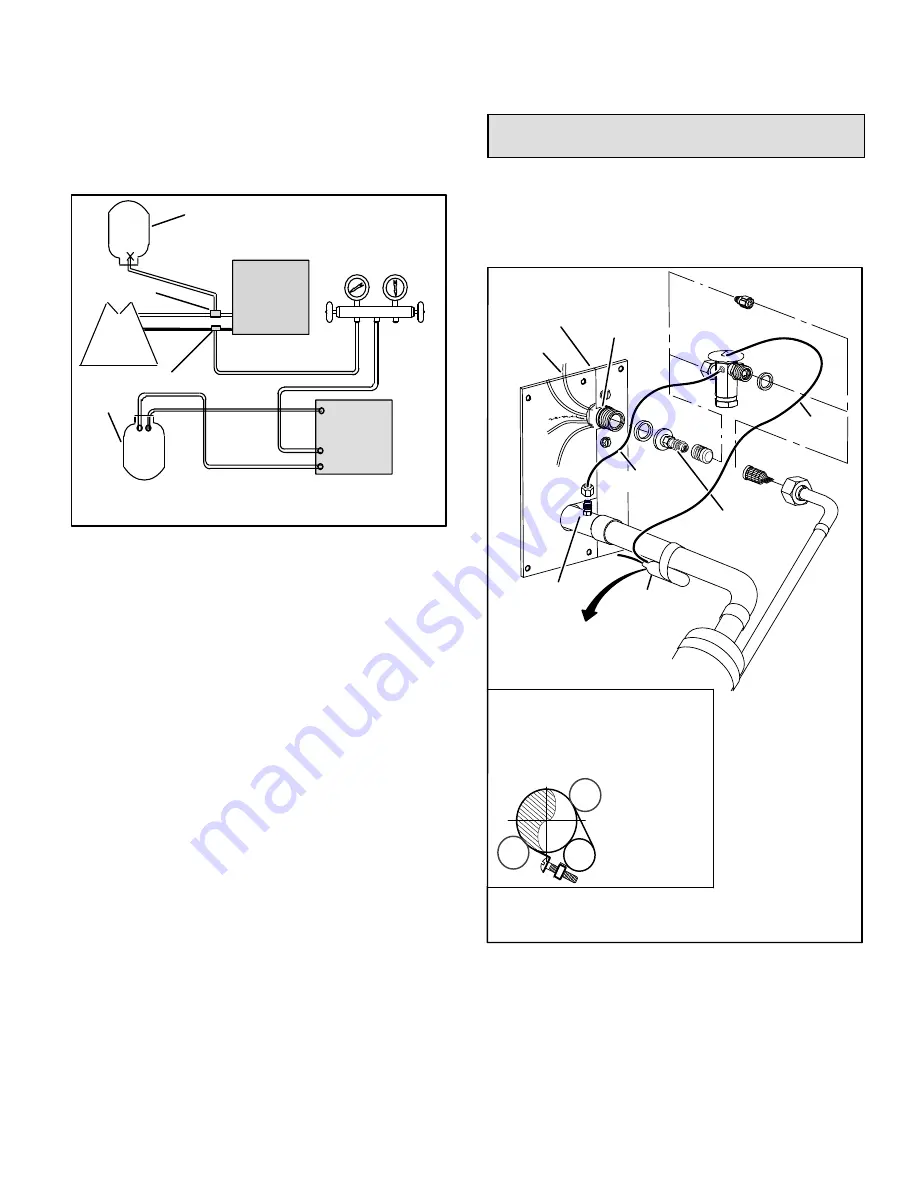

LIQUID

Figure 22. Typical Flushing Connection

PROCEDURE

1. Verify that the existing HCFC−22 refrigerant flow

control device has been removed before continuing

with flushing procedures. Existing devices are not

approved for use with HFC−410A refrigerant and may

prevent proper flushing.

2. Connect an HCFC−22 cylinder with clean refrigerant to

the vapor service valve. Connect the HCFC−22 gauge

set to the liquid line valve. Connect a recovery

machine with an empty recovery tank to the gauge set

as illustrated in figure 22.

3. Set the recovery machine for liquid recovery and start

the recovery machine. Open the gauge set valves to

allow the recovery machine to pull a vacuum on the

existing system line set and indoor unit coil.

4. Invert the cylinder of clean HCFC−22 and open its

valve to allow liquid refrigerant to flow into the system

through the vapor line valve. Allow the refrigerant to

pass from the cylinder and through the line set and the

indoor unit coil before it enters the recovery machine.

5. After all of the liquid refrigerant has been recovered,

switch the recovery machine to vapor recovery so that

all of the HCFC−22 vapor is recovered. Allow the

recovery machine to pull a vacuum on the system.

NOTE − A single system flush should remove all of the

mineral oil from the existing refrigerant lines and indoor

unit coil. A second flushing may be done (using clean

refrigerant) if insufficient amounts of mineral oil were

removed during the first flush.

Each time the system is

flushed, you must allow the recovery machine to pull a

vacuum on the system at the end of the procedure.

6. Close the valve on the inverted HCFC−22 drum and

the gauge set valves. Pump the remaining refrigerant

out of the recovery machine and turn the machine off.

Installing New Refrigerant Metering

Device

XP15 units are used in check thermal expansion valve

(CTXV) systems only. See the indoor unit coil installation

instructions and the Lennox Engineering Handbook for

approved CTXV match−ups and application information.

Table 3 on page 9 lists liquid and vapor line sizes and

corresponding line sets.

NOTE − If necessary, remove HCFC−22 flow control device (fixed

orifice/check expansion valve) from existing line set before instal-

ling HFC−410A approved expansion valve and o−ring.

REMOVE AND DISCARD

SEAL ASSEMBLY (IF

APPLICABLE)

TWO PIECE PATCH

PLATE(UNCASED

COIL ONLY)

VAPOR

LINE

ORIFICE

HOUSING

DISTRIBUTOR

TUBES

LIQUID

LINE

SENSING BULB

(INSULATION REQUIRED)

ACCESS FITTING

(NO VALVE CORE)

SENSING

LINE

EQUALIZER

LINE

ORIFICE

OR

EXPANSION VALVE

(SEE NOTE)

O−RING

STRAINER

(Uncased Coil Shown)

On smaller vapor lines, bulb may be

mounted on top or side-mounted (prefer-

ably at 3 o’clock position).

On 5/8" and larger lines, mount bulb

approximately at the 4 or 8 o’clock posi-

tions; never mount on bottom of line.

12

3 o’clock

9

VAPOR-

Line

Bulb

O−RING

Figure 23. Typical Metering Device Installation

The thermostatic expansion valve or check / thermostatic

expansion valve, can be installed internal or external to the

indoor coil. In applications where an uncased coil is being

installed in a field provided plenum, install the CTXV and

provide an access for field servicing of the CTXV. Refer to

Figure 23 for reference during installation of CTXV.

1. On fully cased coils, remove the coil access and

plumbing panels.