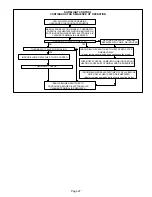

FIGURE 20

TRANSDUCER

(PART #78H5401)

Page 19

TABLE 15

GAS METER CLOCKING CHART

Seconds for One Revolution

G50UH

Natural

LP

G50UH

Unit

1 cu ft

Dial

2 cu ft

Dial

1 cu ft

Dial

2 cu ft

DIAL

−70

55

110

136

272

−90

41

82

102

204

−110

33

66

82

164

−135

27

54

68

136

Natural−1000 btu/cu ft LP−2500 btu/cu ft

IMPORTANT

For safety, shut unit off and remove manometer as

soon as an accurate reading has been obtained.

Take care to replace pressure tap plug.

G− Proper Combustion

Furnace should operate minimum 15 minutes with correct

manifold pressure and gas flow rate before checking com-

bustion. See sections E− and F−. Take combustion sample

beyond the flue outlet and compare to table 16. The maxi-

mum carbon monoxide reading should not exceed 100

ppm.

TABLE 16

Unit

CO

2

%

For Nat

CO

2

%

For L.P.

G50UHi−36A−070

5.8 − 7.8

6.8 − 8.8

G50UHi−36B−090

6.2 − 8.2

6.7 − 8.7

G50UHi−48B−090

6.2 − 8.2

6.7 − 8.7

G50UHi−60C−110

5.9 − 7.9

7.5 − 9.5

G50UHi−60D−135

6.5 − 8.5

7.5 − 9.5

H−Flame Signal

A microamp DC meter is needed to check the flame signal

on the ignition control.

Flame (microamp) signal is an electrical current which passes

from the furnace control through the sensor during unit opera-

tion. Current passes from the sensor through the flame to

ground to complete a safety circuit.

TABLE 17

Flame Signal in Microamps

Ignition Control

Normal

Low

Drop Out

97L48

0.61

0.21 − 0.60

0.20

69M15

0.31

0.25 − 0.30

0.24

To Measure Flame Signal − Ignition Control:

A transducer (Part

#78H5401 available from

Lennox Repair Parts) is

required to measure flame

signal if meter used will not

read a low micro amp sig-

nal. Seefigure20. The

transducer converts mi-

croamps to volts on a 1:1 conversion. See table 17 for flame

signal. A digital readout meter must be used. The transduc-

er plugs into most meters. See figure 21 for proper use of

transducer.

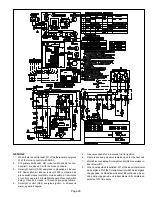

1 − Set the volt meter to the DC voltage scale. Insert

transducer into the VDC and common inputs. Ob-

serve correct polarities. Failure to do so results in

negative (−) values.

2 − Turn off supply voltage to control.

3 − Disconnect ignition control flame sensor wire from the

flame sensor.

4 − Connect (−) lead of the transducer to flame sensor.

5 − Connect (+) lead of transducer to the ignition control sen-

sor wire.

6 − Turn supply voltage on and close thermostat contacts to

cycle system.

7 − When main burners are in operation for two minutes, take

reading. Remember 1 DC volt = 1 DC microamp.

SET DIAL TO MEASURE VDC

(+)

(−) TO

FLAME

SENSOR

NOTE−MUST USE DIGITAL METER

RED COLLAR

INDICATES

POSITIVE

LEAD

(+) TO

IGNITION

CONTROL

SENSOR

WIRE

FIGURE 21

(−)

Содержание G50UHi Series

Страница 6: ...Page 6 FIGURE 1...

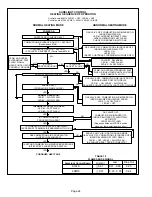

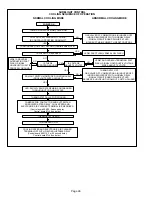

Страница 22: ...Page 22 VII WIRING AND SEQUENCE OF OPERATION...