Page 12

Leak Check

After gas piping is completed, carefully check all piping

connections (factory and field) for gas leaks. Use a leak

detecting solution or other preferred means.

CAUTION

Some soaps used for leak detection are corrosive

to certain metals. Carefully rinse piping thoroughly

after leak test has been completed. Do not use

matches, candles, flame or other sources of igniĆ

tion to check for gas leaks.

NOTE-In case emergency shutdown is required, shut

down main manual gas valve and disconnect main

power to unit. These devices should be properly laĆ

beled by the installer.

IMPORTANT

When testing pressure of gas lines, gas valve must

be disconnected and isolated. See figure 13. Gas

valves can be damaged if subjected to more than

1/2 psig (3.48 kPa).

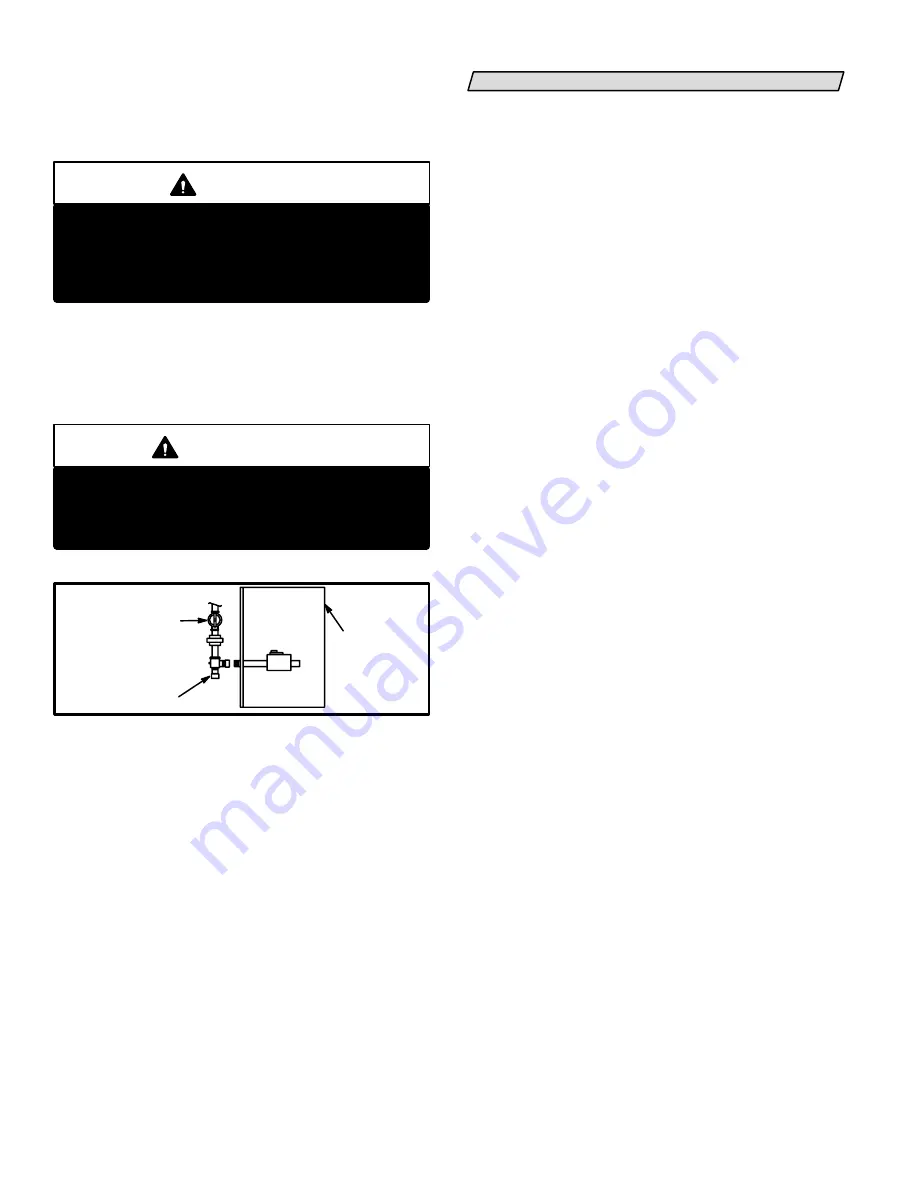

FIGURE 13

MANUAL MAIN

SHUT-OFF VALVE

WILL NOT HOLD

NORMAL TEST

PRESSURE

CAP

ISOLATE

GAS VALVE

FURNACE

The furnace must be isolated from the gas supply sysĆ

tem by closing its individual manual shut-off valve durĆ

ing any pressure testing of the gas supply system at

pressures equal to or less than 1/2 psig (3.48 kPa).

G20RXE Series Units

IMPORTANT-G20RXE series units (units equipped with

flame rods) are approved for use with natural gas only.

ELECTRICAL

Refer to figure 14 for thermostat wiring, figure 15 for

BCC location, figure 16 for pointĆtoĆpoint field wiring,

and figure 17 for schematic wiring diagram and troubleĆ

shooting.

1- Select fuse and wire size according to motor amps.

2- Snaphole plugs are provided on both sides of cabinet

to facilitate wiring.

3- Install room thermostat according to instructions proĆ

vided with thermostat.

4- Install a separate fused disconnect switch near the

unit so power can be turned off for servicing.

5- Route thermostat wire as shown in figure 14. Keep

wire away from draft hood and flue pipe. Do not route

wire across draft hood.

6- Complete wiring connections to equipment using wiring

diagrams provided with unit and in figures 15, 16 and 17.

Use 18 gauge wire or larger for thermostat connections.

7- Electrically ground unit in accordance with local codes

or, in the absence of local codes, in accordance with the

current National Electric Code (ANSI/NFPA No. 70) and

in Canada with the current Canadian Electric Code part

1 (CSA standard C22.1).

8- A 120 volt accessory terminal (ACC) is provided on

the BCC blower control center. Any accessory rated

up to 1 amp can be connected to this terminal and the

neutral leg of the accessory can be attached to any

free 120 volt neutral terminal on the BCC blower conĆ

trol center. The accessory terminal is energized whenĆ

ever the blower is in operation. See figure 15 . A trouĆ

bleshooting flowchart for the BCC blower control is

located at the end of this manual.

9- The continuous fan (CF) 120 volt terminal is used with

an optional continuous low fan kit that is available

from Lennox. The kit allows the furnace blower to run

continuously on low speed.

10- Check the thermostat selector jumper on the BCC

board. The jumper is factoryĆpositioned for use

with a mechanical thermostat.

This jumper must

be repositioned if an electronic thermostat will be

used in the application.

Содержание G20R series

Страница 14: ...Page 14 FIGURE 17 TYPICAL G20R WIRING DIAGRAM ...