Page 17

90

270

150

210

90

150

270

210

90

270

150

210

90

270

150

210

90

270

150

210

JUMPER

JUMPER

JUMPER

JUMPER

NO JUMPER

90 SECOND FAN

OFF TIME

150 SECOND FAN

OFF TIME

210 SECOND FAN

OFF TIME

270 SECOND FAN

OFF TIME

330 SECOND FAN

OFF TIME

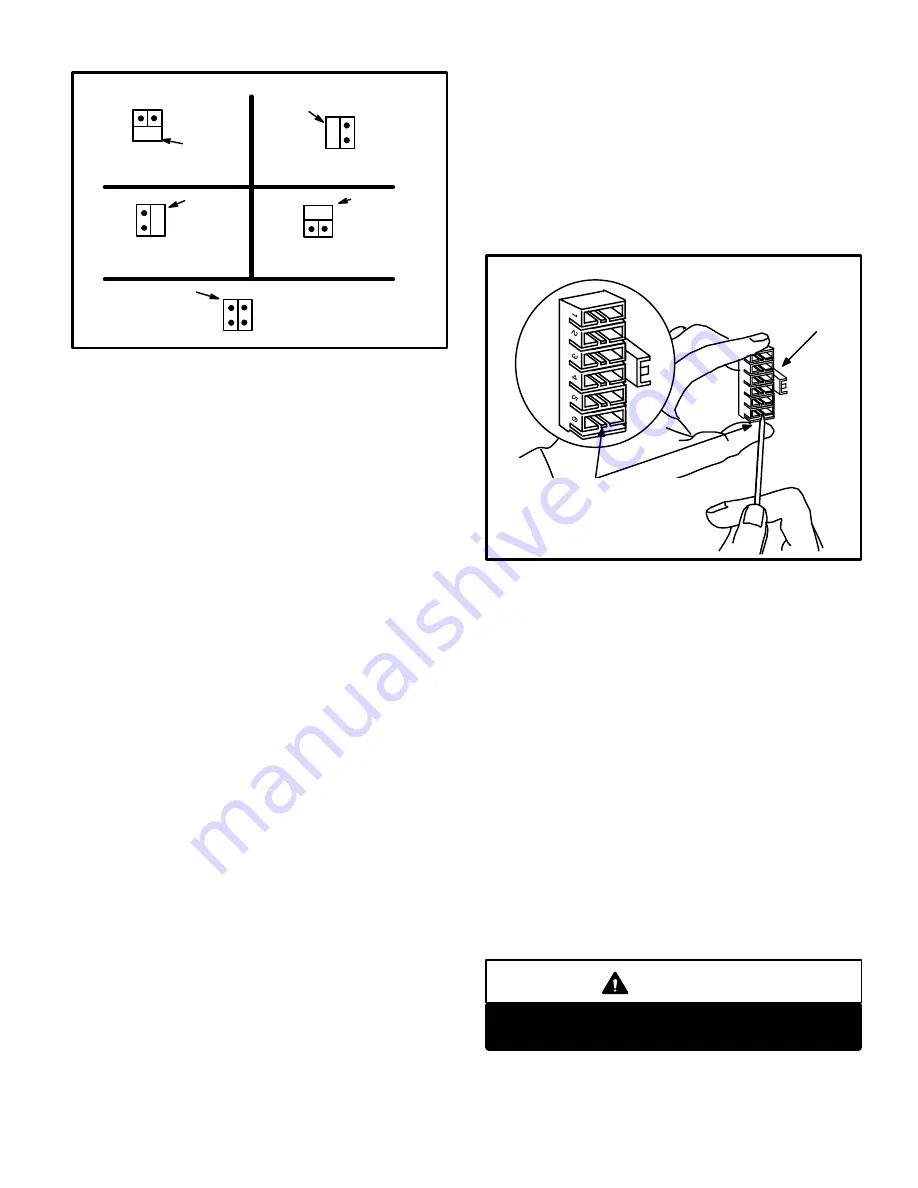

FIGURE 23

FAN OFF TIME ADJUSTMENT

Temperature Rise

Check temperature rise and, if necessary, adjust blowĆ

er speed to maintain temperature rise within range

shown on unit rating plate.

Thermostat Selector Jumper

Check the thermostat selector jumper on the BCC

board. The jumper is factoryĆpositioned for use with a

mechanical thermostat.

This jumper must be reposiĆ

tioned if an electronic thermostat will be used in the apĆ

plication.

Thermostat Adjustment

Thermostat anticipator setting (if adjustable) should be

set according to amps listed on wiring diagram on unit.

Electrical

1- Check all wiring for loose connections.

2- Check for correct voltage at unit (unit operating).

3- Check amp-draw on blower motor.

Motor Nameplate__________Actual__________

Flue and Chimney

1- Check flue pipe, chimney and all connections for

tightness and to make sure there is no blockage.

2- Check unit for proper draft.

Blower Speeds

Blower speed tap selection is accomplished by changing

the taps at the harness connector at the blower motor.

Disconnect harness connector from motor to expose

speed selectors. See figure 24 and unit wiring diagram.

1- Turn off electrical power to furnace.

2- Remove filter access panel.

3- Lift left side filter over left support angle. For easy hanĆ

dling, hold filter at center bottom.

4- Rotate filter sideways and pull it through the blower

access panel opening.

5- Grasp blower motor harness connector located on

back on motor. Depress lock tab and pull connector

from motor.

6- Pull harness connector and wires through blower acĆ

cess panel opening.

7- Select desired taps for heating and cooling. (White =

common, Red = heating, Black = cooling)

8- Depress harness connector tab to release wire termiĆ

nal. Select connector location for new speed (refer to

unit wiring diagram). Insert wire terminal until it is seĆ

curely in place. See figure 24.

9- Replace harness connector to motor until it is securely

in place.

FIGURE 24

BLOWER SPEED TAP SELECTION

HARNESS

CONNECTOR

DEPRESS TAB TO RELEASE

WIRE TERMINAL. SELECT CONĆ

NECTOR LOCATION FOR NEW

SPEED (REFER TO UNIT WIRING

DIAGRAM). INSERT WIRE UNTIL

IT IS SECURELY IN PLACE.

Failure to Operate

If unit fails to operate check the following:

1- Is thermostat calling for heat?

2- Is main disconnect switch closed?

3- Is there a blown fuse?

4- Is filter dirty or plugged? Dirty or plugged filters will

cause unit to go off on limit control.

5- Is gas turned on at meter?

6- Is manual main shut-off valve open?

7- Is internal manual shut-off valve open?

After items 1 through 7 have been checked and unit still

will not start, manually reset vent safety shut-off switch

located at the right side of draft hood. If unit operation reĆ

sumes and then cuts out again, inspect furnace vent sysĆ

tem for proper sizing and installation. Also, check for

vent blockage and for proper draft. If unit still does not

start, reset roll-out switch on burner box. See figure 27. If

unit starts and cuts out, check heat section for blockage.

Pilot and Burner Flame

CAUTION

Check pilot flame and burner flame periodically to

ensure proper operation.

1-

Pilot Flame

-- Pilot flame must surround the end of

flame sensor for proper operation of pilot safety cirĆ

cuit. See figure 25.

Содержание G20R series

Страница 14: ...Page 14 FIGURE 17 TYPICAL G20R WIRING DIAGRAM ...