7

the BFS, the main burner is extinguished (if boiler is running) or

the boiler will not start up.

BLOWER PROVER SWITCH

The Blower Prover Switch (BPS) fig. 4, is similar in construction

to the BFS. It is a single-pole, normally open pressure switch

that will close its contacts when a rising positive pressure of

1.0 in. w.c. (0.25 kPa) is encountered. The contacts will open

when the pressure falls below the fixed set point of 1.0 in. w.c.

(0.25 kPa) The BPS monitors the pressure inside the blower

elbow. If the blower is not operating at a sufficient blowing capacity,

the main burner is extinguished (if boiler is running) or the boiler

will not start up.

LOW GAS SWITCH

The Low Gas Switch (LGS) fig. 5, is a single-pole, normally open

pressure switch that will close its contacts when a rising pressure

of 5.0 in. w.c. (1.24 kPa) is encountered. The contacts will open

when the pressure falls below the fixed set point of 5.0 in. w.c.

(1.24 kPa) The LGS monitors the gas supply pressure to the

boiler. If the gas supply falls below 5.0 in. w.c. (1.24 kPa), the

main burner is extinguished (if boiler is running) or the boiler will

not start up.

FIGURE 5. LOW GAS SWITCH (LGS)

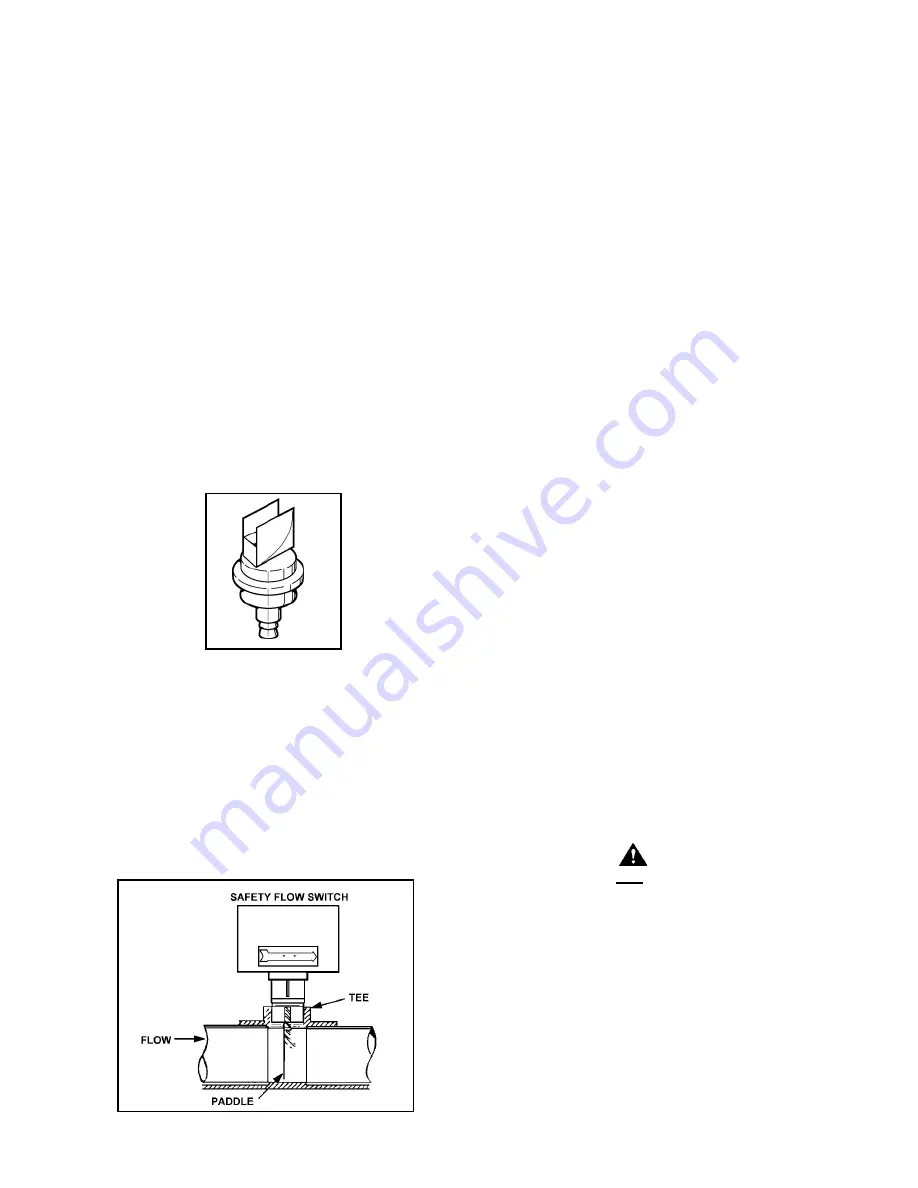

WATER FLOW SWITCH

The Water Flow Switch (WFS) fig. 6, is installed at the boiler water

outlet to prevent main burner operation in the event of inadequate

water flow through the boiler. The WFS is a single-pole, normally

open switch that will close its contacts when an increasing water

flow rate of approximately 25 GPM (1.61 lps) is encountered. The

contacts will open when the flow rate drops below this setting,

extinguishing the main burner flames (if boiler is running) or the

boiler will not start up.

FIGURE 6. WATER FLOW SWITCH (WFS)

AIR SHUTTER

The blower is equipped with an air shutter assembly for fine

adjustment of the air to gas ratio The assembly consists of a

shutter flange and the air shutter. The shutter may require

adjustment to achieve ideal start-up characteristics when fine tuning

the boiler for correct combustion specifications. Refer to the

Start-Up Procedures, part number 192077 Rev. 1, for the proper

combustion specifications and limits. If necessary, the shutter

may be adjusted by loosening the two nuts used to hold the shutter

and blower adapter assembly in place on the inlet of the blower.

Once the unit is set to the specifications called for in the Start-Up

Procedures, tighten the nuts to lock the shutter in place.

BLOWER SPEED CONTROL

The Blower Speed Control (BSC) permits variation of speed of

the blower during boiler (LB/LW-500 only) start-up. When the

1502 Control Board energizes the igniter, the BSC will lower the

speed (RPM) of the blower to a preset level. This lower speed

will be maintained until the igniter is de-energized by the Control

Board. Then, the blower will return to its normal operating speed.

COMBINATION GAS CONTROL

The Combination Gas Control (CGC) is a gas valve or valves that

controls the supply of gas to the main burner during operation of

the boiler. The CGC includes a manual main shutoff valve, two

(2) automatic valves and a pressure regulator, see figure 15.

The two-position gas control knob has “ON” and “OFF” positions

that allows or prevents the flow of gas to the main burner,

respectively. The first automatic valve is solenoid operated and

opens and closes when the main valve terminal on the Control

Board is energized or de-energized, respectively. The second

automatic valve is diaphragm operated and opens under control

of the pressure regulator and closes if gas or power supply is

interrupted. The pressure regulator is adjustable and maintains

an almost constant gas outlet pressure under wide fluctuations

in gas supply pressure.

MANUAL RESET LIMIT (E.C.O)

This device prevents the water temperature from exceeding 250°F

(121°C). It is located in the outlet waterway within the outlet

temperature sensing device and is monitored by the Control

Board. Commonly referred to as the “emergency cut out”, it is a

manually resettable control. The “ADJUST”, “SELECT” or

“ENTER/RESET” button on the display board must be depressed

to reset the unit if the water temperature reaches this limit. See

figure 20.

CAUTION

LIMIT CONTROLS ARE NOT TO BE USED AS A THERMOSTAT OR

OPERATING CONTROL.

AUTOMATIC RESET LIMIT

This limit is a safety device in series with the ignition system. Set

the limit control to a minimum of 30°F (16°C) above the maximum

designed system temperature. If the boiler outlet water

temperature should exceed the automatic reset limit setting, the

main gas valves will close. The automatic reset limit control is

factory set at 180°F (82°C) and has an adjustable range from

110 to 240°F (43° to 116°C). The operating differential is also

adjustable from 5 to 50°F (3° to 28°C).

ON/OFF SWITCH

The ON/OFF Switch is a single-pole, single-throw rocker switch.

This switch provides 120V from the line source to the boiler.

Содержание LB 1000

Страница 22: ...22 FIGURE 16 CONNECTION DIAGRAM ...

Страница 23: ...23 FIGURE 17 SCHEMATIC DIAGRAM ...