17

Manifold headers are recommended for split systems with or

without zone values and also those installations with zone

circulators. If the system is to be split at remote points, good

practice requires special attention be given to main pipe sizing

to allow balancing of water flow.

5. COOLING PIPING

When the boiler is used in conjunction with a refrigeration

system it must be installed so that the chilled medium is piped

in parallel with the boiler. Appropriate flow control valves,

manual or motorized, must be provided to prevent the chilled

medium from entering the boiler.

Water temperature in the heating system must be reduced to

less than 100°F (38°C) before cooling system is started, or

damage to the chiller unit may occur.

If the boiler is connected to chilled water piping or its heating

coils are exposed to refrigerated air, the boiler piping system

must be equipped with flow valves or other automatic means

to prevent gravity circulation through the boiler during the

cooling cycle.

Primary/secondary pumping of both the chiller(s) and the

boiler(s) is an excellent winter-summer change-over method,

because cooling flow rates are so much more than heating

flow rates. In this way each system (heating or cooling) is

circulated independently.

6. CIRCULATING PUMP

FOR HOT WATER HEATING SYSTEMS - LB MODELS

, the

circulating pump is NOT provided and must be field-installed.

NOTE: If a system pump is to be installed on a Legend LB

model, the maximum rating of the pump motor must not

exceed 1 hp.

INTERNAL CONTAMINANTS

The hydronic system must be internally cleaned and flushed after

a new or replacement boiler has been installed, to remove

contaminants that may have accumulated during installation. This

is doubly important when a replacement boiler is installed into

an existing system where Stop Leak or other boiler additives

have been used.

Failure to clean and flush the system can produce acid

concentrations that become corrosive, cause gases to form that

block water circulation or lead to formation of deposits on the

boiler surfaces, any of which could result in damage to the system

and circulator.

All hot water heating systems should be completely flushed with

a grease removing solution to assure trouble-free operation. Pipe

joint compounds, soldering paste, grease on tubing and pipe all

tend to contaminate a system

Failure to flush contaminants from a system can cause solids to

form on the inside of boiler exchangers, create excessive amounts

of air and other gases to block circulation, foul various system

accessories and even deteriorate circulation seals and impellers.

HOT WATER SUPPLY BOILER SYSTEM-

GENERAL WATER LINE CONNECTIONS

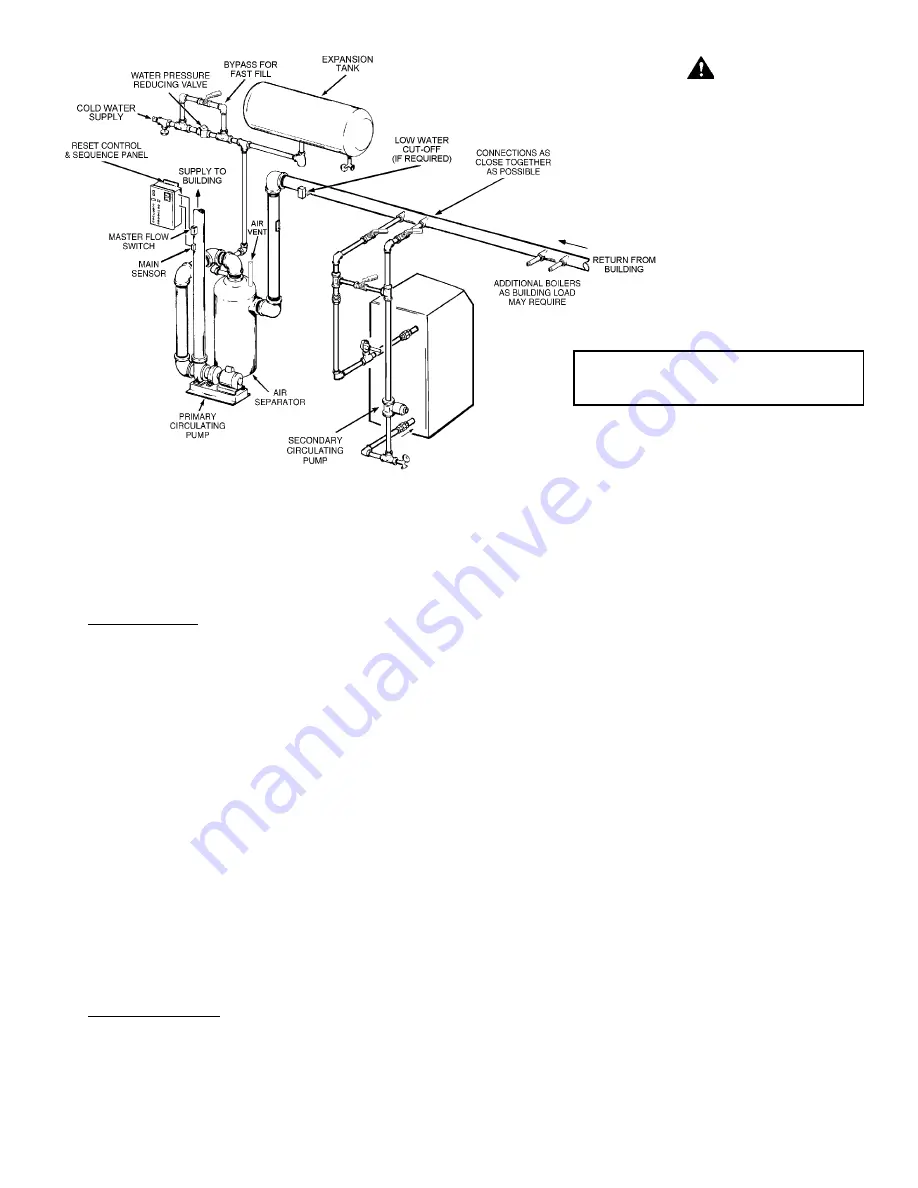

This section provides detailed installation diagrams for a typical

method of application for the unit.

Piping diagrams will serve to provide the installer with a reference

for the materials and methods of piping necessary for installation.

It is essential that all water piping be installed and connected as

shown on the diagrams. Check the diagrams to be used

thoroughly before starting installation to avoid possible errors

and to minimize time and material cost.

It is essential that all water piping be installed and connected as

shown on the diagrams. Check the diagrams to be used

thoroughly before starting installation to avoid possible errors

and to minimize the time and material cost.

FIGURE 12. TYPICAL PRIMARY, SECONDARY PIPING

• INSTALL IN ACCORDANCE WITH ALL LOCAL CODES.

• WHEN BLOW DOWN VALVE IS REQUIRED, INSTALL

IN PLACE OF THE DRAIN VALVE SHOWN.

DANGER

TEMPERATURE SETTING SHOULD NOT EXCEED

SAFE USE TEMPERATURE AT FIXTURES. SEE

WATER TEMPERATURE CONTROL WARNING ON

PAGE 28. IF HIGHER PREHEAT TEMPERATURES

ARE NECESSARY TO OBTAIN ADEQUATE

BOOSTER OUTPUT, ADD AN ANTI-SCALD VALVE

FOR HOT WATER SUPPLIED TO FIXTURES.

Содержание LB 1000

Страница 22: ...22 FIGURE 16 CONNECTION DIAGRAM ...

Страница 23: ...23 FIGURE 17 SCHEMATIC DIAGRAM ...