Hardware

installation manual of the multi-axis drive MX3660

Leadshine Technology Co., Ltd

Leadshine America, Inc.

Page 6/25

11/F, Block A3, iPark,

No.1001 Xueyuan Blvd, Nanshan District, Shenzhen, China

25 Mauchly, Suite 318, Irvine, CA 92618, USA

Tel:

86-755-26409254

Fax: 86-755-26402718

Tel: 1-949-608-7270

Fax: 1-949-608-7298

Web

:

www.leadshine.com

Email:

Web:

www.leadshine.com

Email:

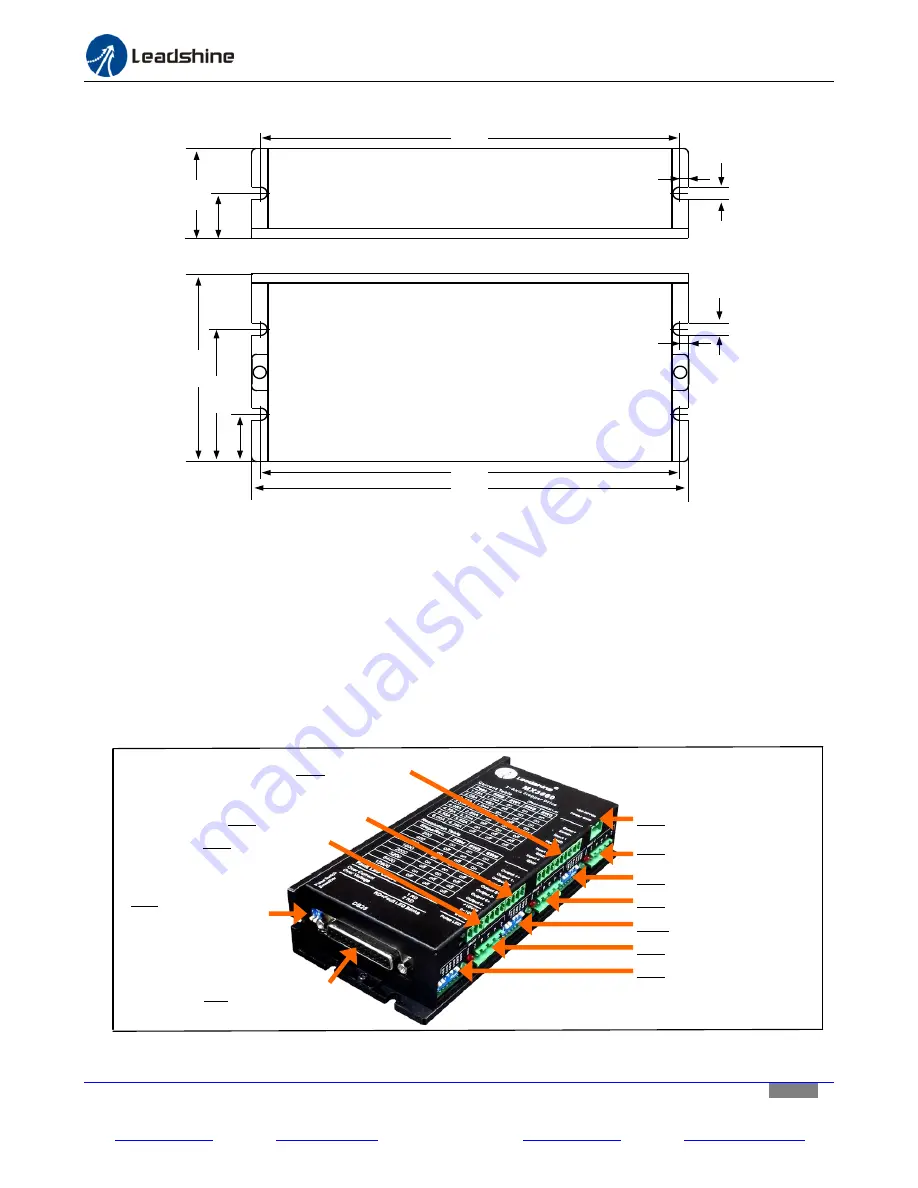

5.

Dimensions

162±0.5

169±1.5

19

.5

±0

.3

54

.5

±0

.3

77

.5

±1

.5

5

162±0.5

16

±0

.2

37

±1

.5

5

3.5

3.5

Figure 2 MX3660 dimensions

6.

Get Started

Before you start hardware connection, refer to the following MX3660 layout diagram (figure 3) for connector/DIP

switch location. Read the MX3660 datasheet for each connector explanation. Then, get the following prepared:

A 24-54 VDC power supply.

Up to 3 stepper motors depending on how many axes that MX3660 will power in your application.

A source of step signals, such as a motion controller, PLC, or a PC-based control system (Mach3/4, EMC, etc.).

A small flat blade screw driver for tightening the screw connectors of the MX3660.

Whatever optional external devices needed to be controlled through the built-in outputs and inputs.

Figure 3

MX3660 layout

CN1:

DB25 Connector

DP3:

Z-Axis DIP switch

CN5:

Z-Axis Motor Connector

DIP2:

Y-Axis DIP switch

DP1:

X-Axis DIP switch

CN3:

X-Axis Motor Connector

CN4:

Y-Axis Motor Connector

CN8:

Analog Output

CN7:

Digital Outputs

CN6:

Digital Inputs

CN2:

Power Connector

DP4:

Pulse Switch &

Smoother switch