16

For Tech Tip Instructions

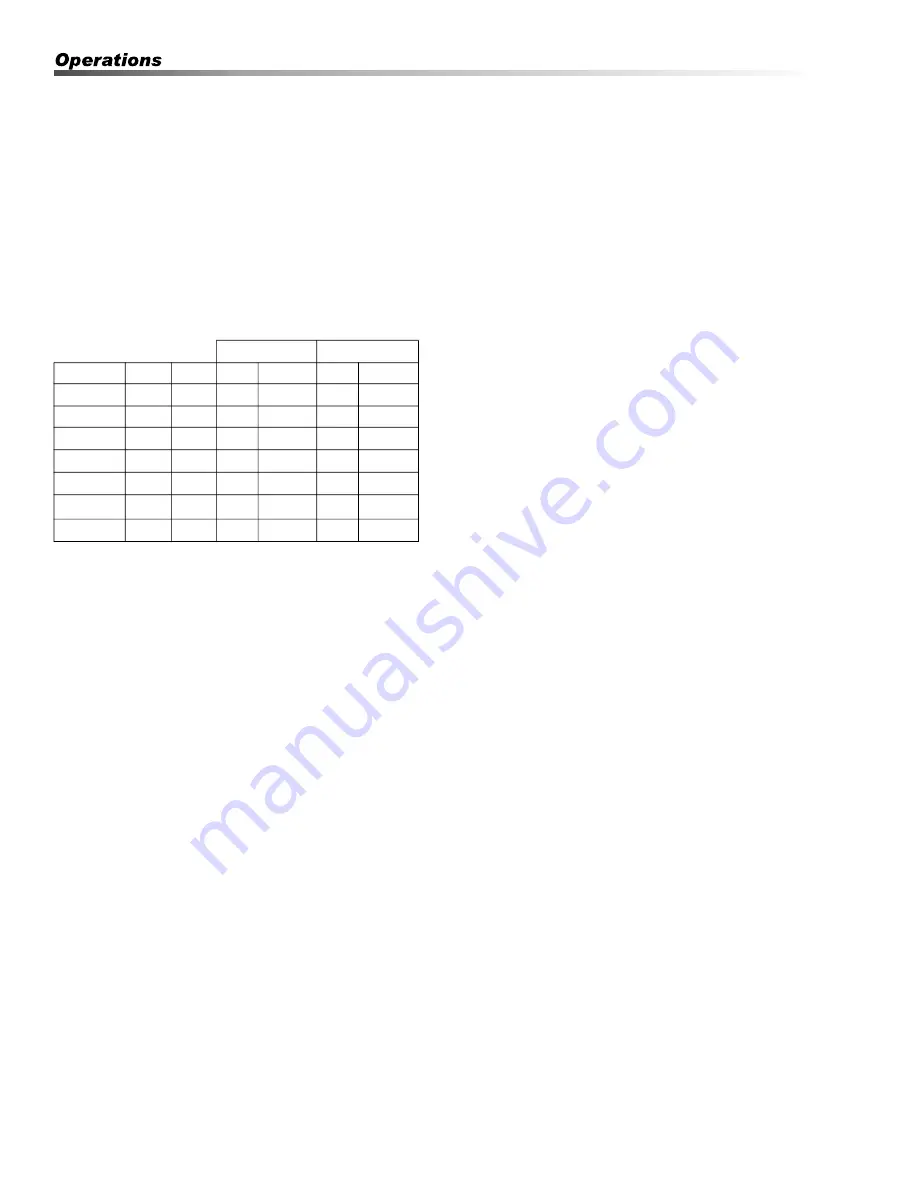

Combustion efficiency in a natural draft pressure

washer is significantly influenced by the heat created

inside the coil, the design of the coil and flue and the

length and diameter of the exhaust stack. The table

below shows data included in the operator’s manual for

flue and stack sizes and gas manifold pressure

settings. These sizes are critical for achieving proper

combustion and acceptable emissions.

Testing has shown that simply adding a 36” stack

extension to the flue adapter on top of the pressure

washer can reduce the outlet temperature by 5-10°F.

This occurs by inducing a higher pressure differential at

the exit of the coil and increasing the flow of air into the

combustion process and through the stack. Most or all

of the lost outlet temperature can be recovered by

installing and adjusting a damper in the stack. However

this adjustment must only be performed by a trained

technician using a combustion analyzer.

The damper should be installed 24-36” above the flue

adapter. The pressure washer can be operated safely

with the damper fully open but with the lower outlet

temperature. If the damper is closed too far there will

not be enough oxygen to burn all of the fuel. This will

cause higher and potentially dangerous levels of CO in

the flue gas emissions.

To adjust the damper for proper combustion and effi-

ciency perform the following:

1. If there is no sample port for the analyzer probe,

drill a hole slightly larger than the combustion

analyzer probe through the exhaust stack at a point

about 18” above the flue adapter.

2. Insert the probe of the combustion analyzer so that

the tip is at the center of the stack.

3. Open the damper to the fully open position.

4. Start the pressure washer and allow it to heat up

for at least 20 minutes before making any adjust-

ments.

5. Note the values for % Excess Air and/or %

Oxygen.

6. Close the damper in small increments until %

Excess Air is between 20-30% and/or % Oxygen is

4-5%.

This process can also be used when turning down the

firing rate for high altitude installations above 2000 ft.

1. Adjust the gas pressure down 4% for every 1000 ft

of elevation.

Example: Recommended firing rate for a 4.8@3000

is 4.2 wc-in. For an installation at 3500 feet reduce

this pressure by 16% by setting the manifold pressure

to 4.2*.84 = 3.5 wc-in.

A manometer capable of reading to at least the nearest

0.1 wc-in will be required for this adjustment. These can

be found for less than $200 (Extech HD700).

2. Follow steps 1-6 above to optimize the outlet

temperature of the pressure washer.

Installations Above 2000 ft:

Installation at altitudes greater than 2000 ft will require

adjustments to the gas manifold pressure.

For installations above 2000 feet the firing rate should

be reduced by 4% per 1000 feet. Example: Recom-

mended firing rate for a 4.8@3000 is 4.2 wc-in. For an

installation at 3500 feet reduce this pressure by 16% by

setting the manifold pressure to 4.2*.84 = 3.5 wc-in.

This adjustment should only be made by a properly

trained service technician. A manometer capable of

reading to the nearest 0.1 wc-in will be required for this

adjustment.

In Canada, certification for installation at altitudes over

4500 feet is the jurisdiction of local authorities.

NG

LP

Model

Collar Stack wc-in kBTU-in wc-in kBTU-in

3.5@2000

10"

8"

3.6

310

7.8

310

4.0@3000

10"

8"

3.4

354

7.4

354

4.0@2200

10"

8"

5.1

364

11.2

364

5.0@3000

10"

10"

4.2

415

9.1

415

5.0@2300

10"

10"

4.7

437

9.5

439

6.0@3800

12"

10"

4.3

507

7.4

507

8.0@3800

12"

12"

3.1

658

7.0

658

Landa VHG Operator’s Manual 8.913-952.0 - BR

Содержание VHG

Страница 2: ...2 Landa VHG Operator s Manual 8 913 952 0 BR...

Страница 10: ...10 Installation VHG 4 5 Landa VHG Operator s Manual 8 913 952 0 BR...

Страница 11: ...11 Installation VHG 6 8 Landa VHG Operator s Manual 8 913 952 0 BR...

Страница 38: ......