22

Section 3: Operating Instructions

RC3615 (540 RPM) and RCM3615 (1000 RPM) Rotary Cutters 330-502M

4/20/15

Table of Contents

Section 3: Operating Instructions

Startup Checklist

Hazard control and accident prevention are dependent

upon the awareness, concern, prudence, and proper

training involved in the operation, transport, storage, and

maintenance of the Rotary Cutter. Therefore, it is

absolutely essential that no one operates the cutter

without first having read, fully understood, and become

totally familiar with the Operator’s Manual. Make sure the

operator has paid particular attention to:

•

Important Safety Information

, pages 1 to 9

•

Section 1: Assembly & Set-up,

page 11

•

Section 2: Adjustments

, page 20

•

Section 3: Operating Instructions

, page 22

•

Section 4: Options & Accessories

, page 29

•

Section 5: Maintenance & Lubrication

, page 32

Also make sure the operator has completed the

Operating Checklist below before using the cutter.

Safety Information

!

DANGER

Operate only tractors equipped with Roll-Over Protective

Structure (ROPS) and seat belt. Fasten seat belt snugly and

securely to help protect operator from being thrown, crushed,

or severely injured in a rollover or from falling off the tractor

and being ran over by the tractor and/or cutter.

!

DANGER

Never allow riders including children on the tractor or cutter.

They can fall and be ran over, become entangled in rotating

components, and/or pinched by moving components causing

serious injury or death.

!

DANGER

Do not operate cutter with a bent or broken driveline. Such a

driveline can break apart while rotating at high speeds

causing serious injury or death. Always remove Rotary Cutter

from service until damaged driveline is repaired or replaced.

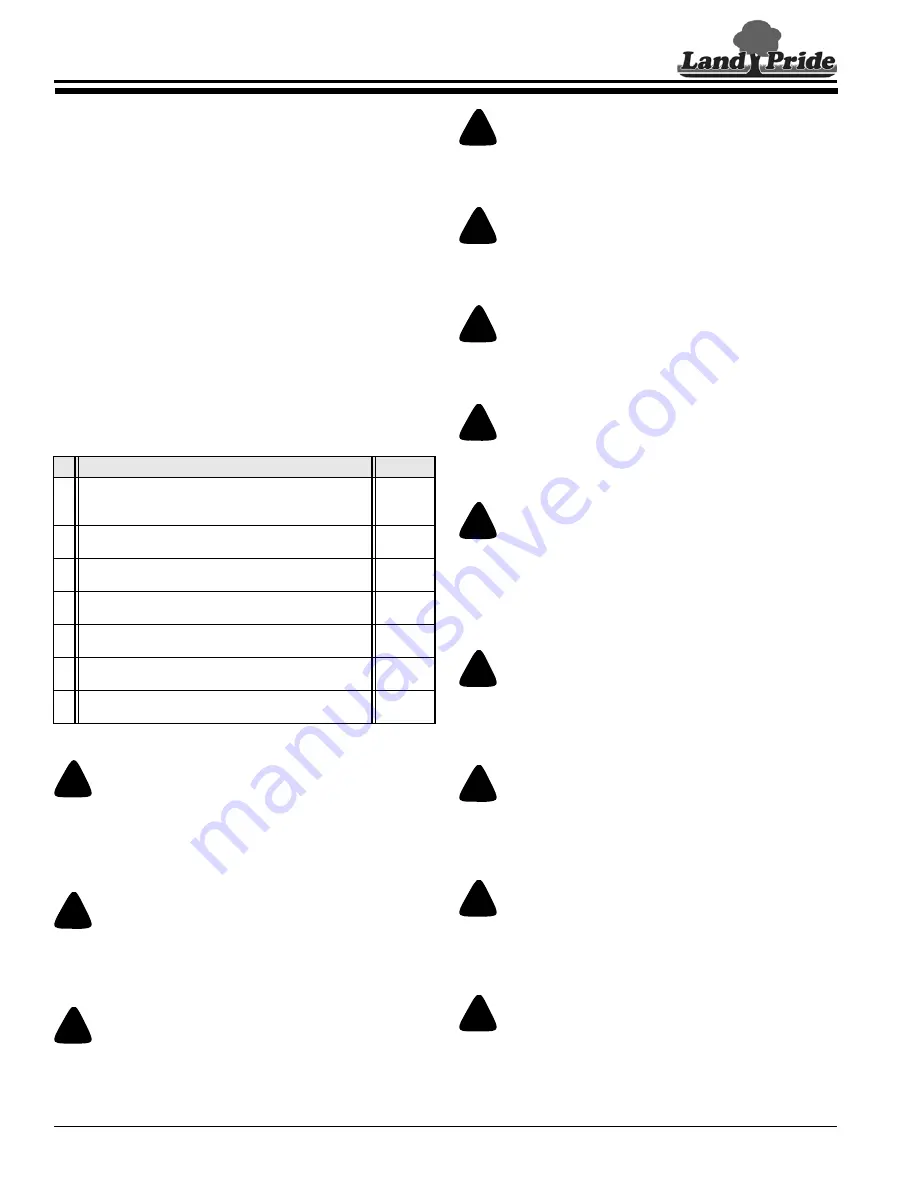

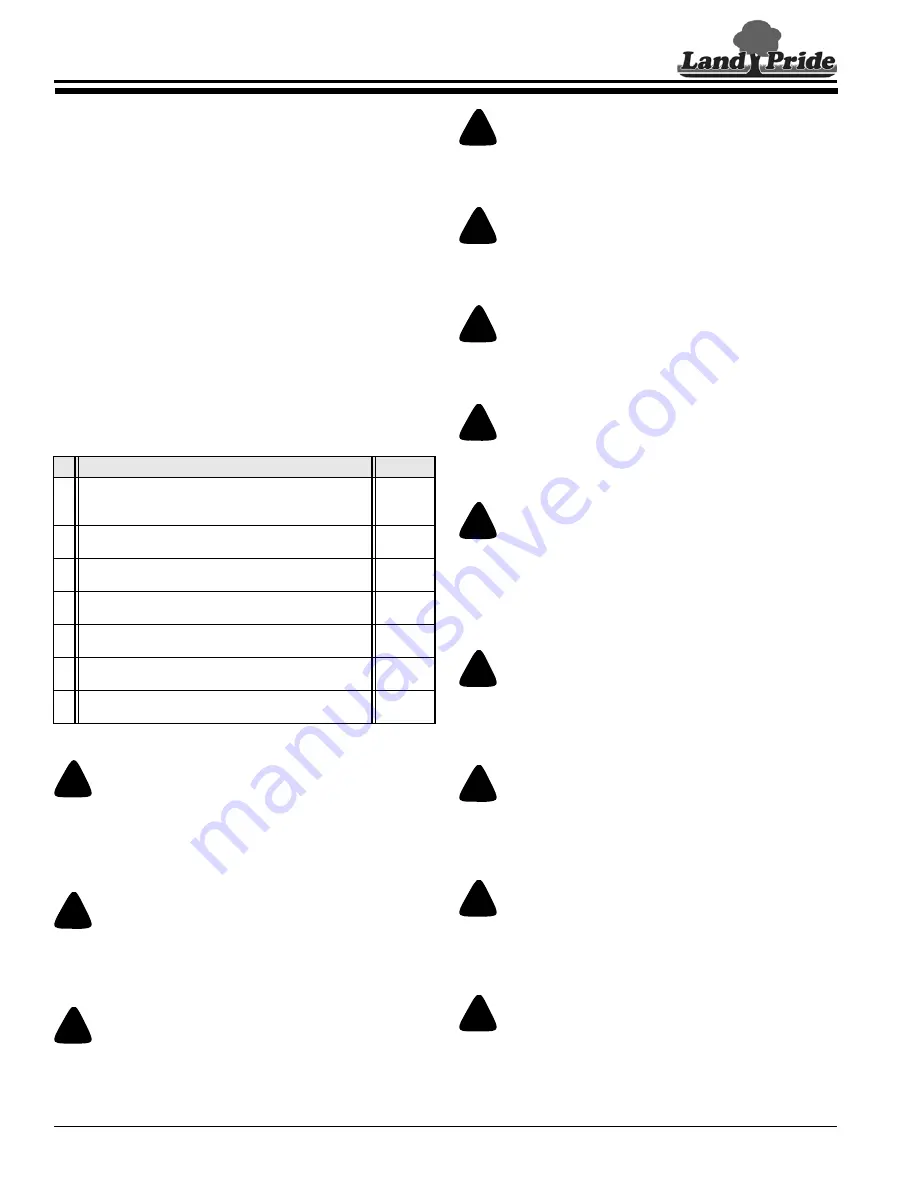

Operating Checklist

✔

Check

Page

Make sure all guards, and shields are in place and in

good working condition. Refer to "Important Safety

Information".

Page 1

Follow hook-up and driveline installation instructions.

Refer to "Section 1: Assembly & Set-up".

Page 14

Make all required adjustments.

Refer to "Section 2: Adjustments".

Page 20

Preform all required maintenance.

Refer to "Section 5: Maintenance & Lubrication".

Page 32

Lubricate cutter and driveline as needed.

Refer to "Lubrication Points".

Page 40

Lubricate all gearboxes and replace oil plugs

properly. Refer to Gearbox lubrication.

Page 42

Check cutter initially and periodically for loose bolts

and pins. Refer to “Torque Values Chart”.

Page 50

!

DANGER

Tractor PTO shield, gearbox shaft shield and driveline shields

must be secured in place when operating cutter to avoid injury

or death from entanglement in driveline.

!

DANGER

Always disconnect main driveline from tractor PTO before

servicing underside of cutter. PTO can be engaged if tractor is

started causing cutter damage, bodily injury or death.

!

DANGER

Do not operate cutter with one or both wings folded up. This

can cause the driveline to break apart and throw objects at the

operator or a bystander causing serious injury or death.

!

DANGER

Do not use cutting blades as a fan. Cutting blades are not

properly designed or guarded for this use. Using cutter as a

fan can result in injury and/or death.

!

DANGER

Keep others away from the cutter while it is operating. Rotary

Cutters have the ability to discharge objects at high speeds

causing serious injury or death. The use of front & rear safety

guards is strongly recommended and should always be used

when cutting along highways and in areas where bystanders

are present. Stop blade rotation if bystanders are nearby.

!

DANGER

Do not operate cutter without both wings attached. Removing

one wing will expose blades and increase risk of rollover.

Removing both wings will expose blades on both sides.

Exposed blades can result in serious injury and/or death.

!

DANGER

Do not engage tractor PTO while hooking-up and unhooking

driveline or while someone is standing near the driveline. A

person’s body and/or clothing can become entangled in the

driveline resulting in serious injury or death.

!

DANGER

Never place hands or feet under the deck or attempt to make

adjustments to the cutter with PTO engaged. Cutter blades

rotating at high speeds cannot be seen and are located close

to the deck housing. Body extremities can be cut off instantly.

!

DANGER

Do not operate on or travel across steep inclines where a

tractor or cutter could roll-over resulting in serious injury or

death. Consult your tractor’s manual for acceptable inclines

the tractor is capable of traveling across.