Section 5: Maintenance & Lubrication

11/2/18

33

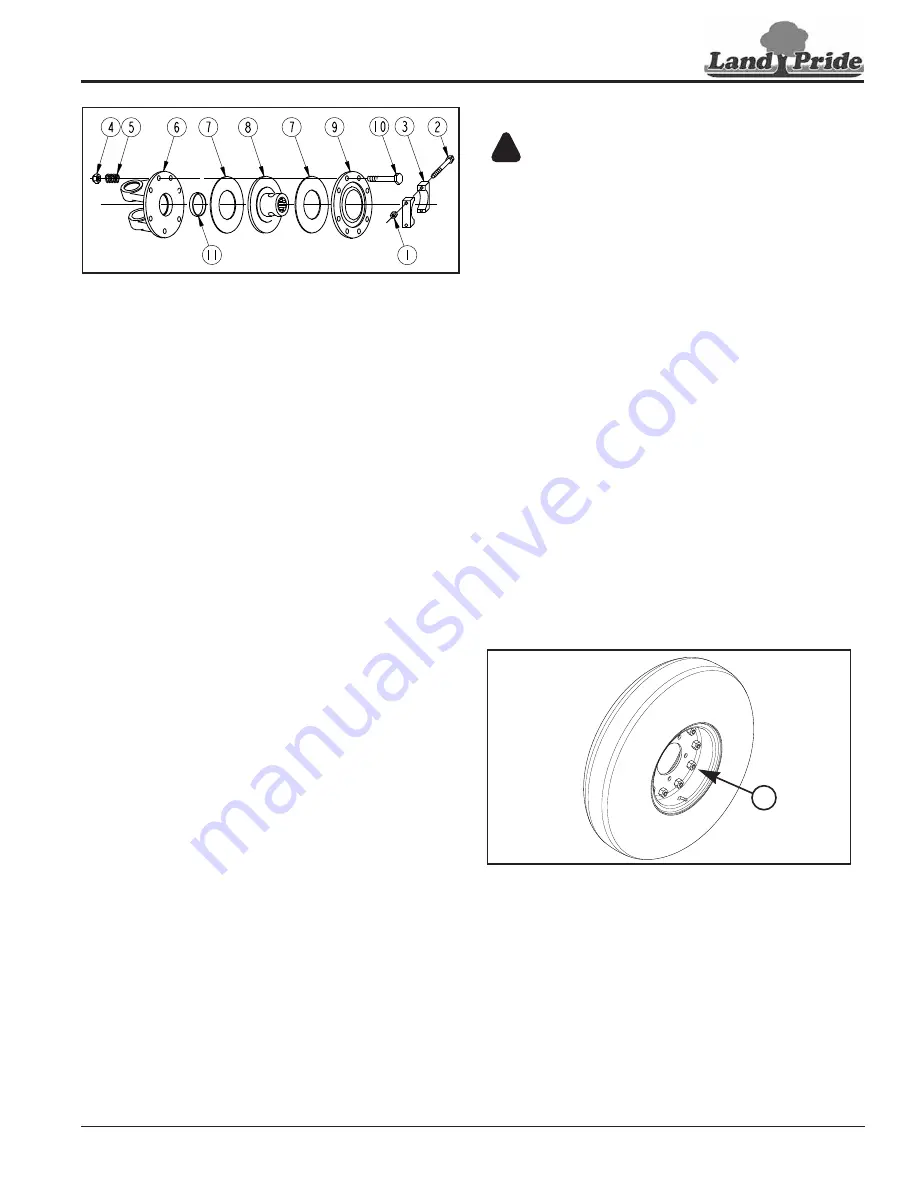

2-Plate Clutch Assembly

Figure 5-7

3. Remove nuts (#1), bolts (#2), and bridge blocks (#3).

4. Remove spring retainer nuts (#4), springs (#5), and

bolts (#10).

5. Separate all friction disks (#7), flanged yoke (#6),

clutch support (#8), and pressure plate (#9).

Clutch Inspection

Inspect all parts for excessive wear and condition. Clean

all parts that do not require replacement.The original

friction disk thickness is 1/8" (3.2mm) and should be

replaced if thickness falls below 3/64" (1.1 mm). If

clutches have been slipped to the point of “smoking”, the

friction disks may be damaged and should be replaced.

Heat build-up may also affect the yoke joints.

Clutch Assembly

1.

Make sure bushing (#11) is still seated in flanged

yoke (#6).

2. Reassemble each friction disk (#7) next to the metal

plate it was separated from as shown.

3. Insert all 8 bolts (#10) through pressure plate (#9)

and flanged yoke (#6).

4. Insert springs (#5) over bolts (#10) and secure with

spring retainer nuts (#4). Tighten each nut to the

measured distance “A” recorded in step 2 under

5. Do not install bridge blocks (#3) until installation of

clutch to divider gearbox. At that time, secure slip

clutch to the output shaft with bridge blocks (#3),

bolts (#2), and nuts (#1). Tighten nuts (#1) to the

correct torque.

6. Pull/push on the slip clutch end of driveline to make

sure it is secured to the output shaft.

7.

Push/pull on opposite end of driveline to make sure it

is secured to the input shaft on the blade spindle

gearbox.

35966

Tire Maintenance

WARNING

!

To avoid serious injury or death:

•

Tire changing can be dangerous and should be performed

by trained personnel using correct tools and equipment.

When removing and installing wheels, use wheel handling

equipment adequate for the weight involved.

•

Always release all air pressure in air-filled airplane tires

before removing hardware bolting the split rims together.

Not doing so can cause the split rims to blow apart instantly

and could result in serious injury or death.

•

Tire changing can be dangerous and should be performed

by trained personnel using correct tools and equipment.

When removing and installing wheels, use wheel handling

equipment adequate for the weight involved.

•

Do not weld on or heat a rim. High heat can weaken and/or

warp the rim and damage the tire. Air pressure inside the

tire can increase enough to cause an explosion.

1.

Check tires for low air pressure, missing nuts,

missing lug bolts, wear, separated rubber, and bent,

broken, or cracked wheel rims.

2. Inflate air-filled tires to the proper pressure. Refer to

3. Replace wheel rims and tires as needed with

genuine Land Pride parts. Do not loosen split rim

hardware (#1) until all air pressure in the tire has

been removed.

Air-filled Airplane Tires with split Rims

Figure 5-1

33922

1