16

During laminate process, correct temperature and speed setting can improve the degree of completion

for the processed material.

Point

Laminate film that passes through heat rollers becomes soft by heat, and

unnecessarily high heat on the film can make the film get caught by the roller.

→ Entangled

Thin paper and laminate film do not require as much heat compared to thick

paper and laminate film. Quickly pass them through the rollers (or decrease

surface temperature of the roller).

→ If it is passed too slowly, the film can easily get caught.

On the contrary, thick paper requires large heat. If it is passed through heat rollers

too fast, glue inside the film may not melt down and can turn white. In this case,

slow the speed down to slowly apply heat (or increase surface temperature of the

roller).

Note

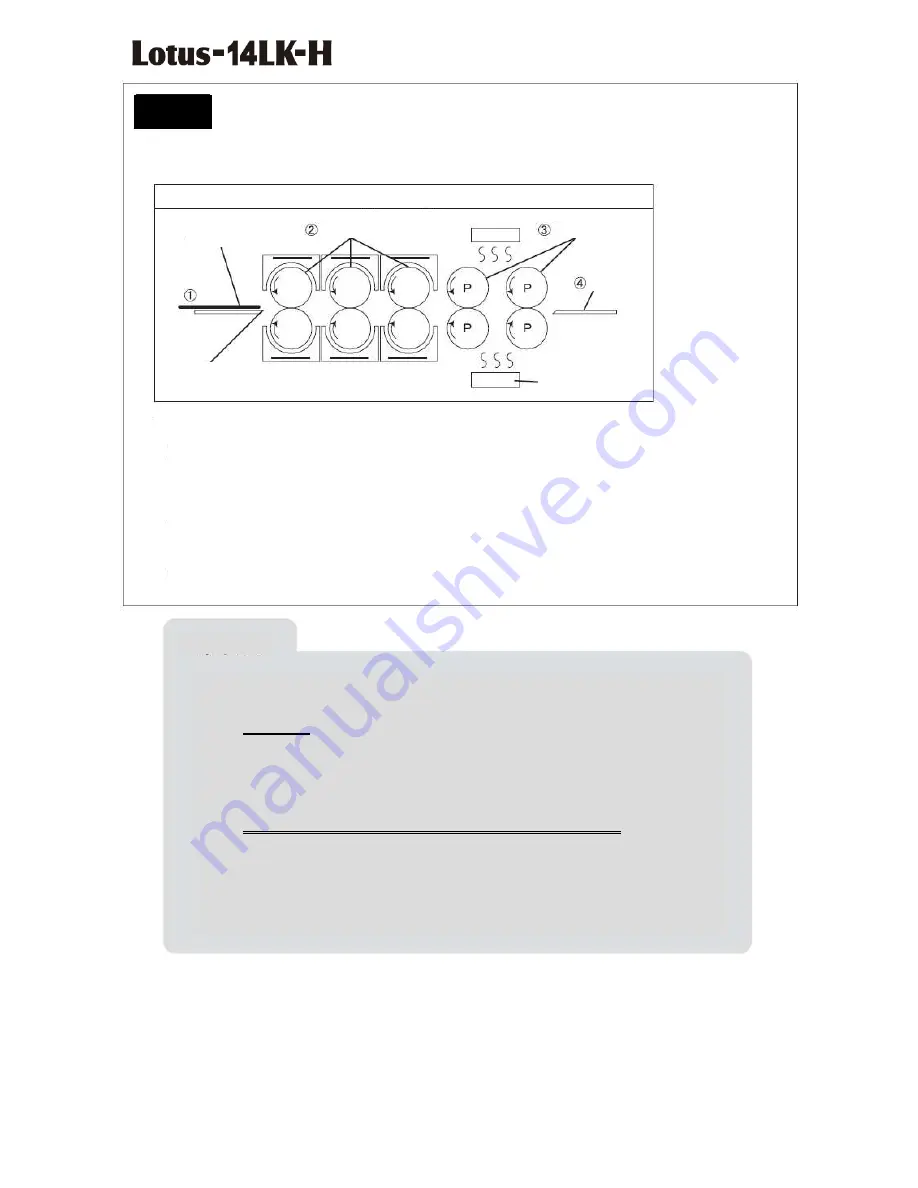

Pull roller

Heat roller

Paper (film)

Cooling

plate

Cooling fan

Paper insertion

hole

Flow of laminate film

Internal structure of this product

①

Insert laminate film at the paper insert hole.

②

Laminate film is passed through rollers heated by external heater three times.

Here, approximate surface temperature of heat rollers is the temperature setting on the

operation panel. Glue inside the film is melted down to attach the paper to the film.

(The film becomes soft.)

③

After passing through heat rollers, it is passed through Pull rollers.

Pull rollers pull the heated laminate film to cool it down.

(Softened film is hardened again)

④

Laminate film is cooled down using cooling fan and cooling plate.

Processed material comes out of the machine after passing through Pull rollers.

Содержание Lotus-14LK-H

Страница 1: ......