-7-

www.igmtools.com

6.2 Installing/Removing Faceplate & Hand Wheel

WARNING!

Unplug the machine from power source!

TIP

Do not over torque the threading, only firm pressure is required.

TIP

Remove set screws prior to removing faceplate. The screws are

located on the flat part of the spindle. Do not disassemble by force.

Remove screws completely or you can damage the spindle.

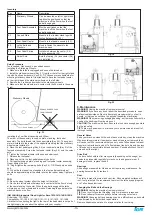

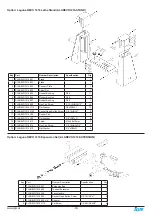

Fig. 11

Fig. 11: Faceplate installation. (1) Spindle Lock. (2) Faceplate

wrenching hole. (3) Knockout rod or Faceplate wrench. (4) Set

screws.

Simply screw the faceplate intro the spindle threading. The spindle is with

M33 x 3,5 mm right hand threads. There is a cutting slot on the spindle for

the set screws.

Tools needed: Faceplate wrench (PLAREVO1836-1136) or Knockout rod

(PLAREVO1216-1103A) and 3mm Hex wrench

1. Make sure the lathe is unplugged and cannot be turned on.

2. Position the banjo out of the way to prevent damage.

3. Check that the set screws (Key 4) are not engaged. Remove all set

screws that are tightened down with Hex wrench.

4. Press the spindle lock (Key 1) inward to lock the spindle. Rotate the

spindle a bit to line it up with the pin hole.

5. With spindle lock (Key 1) engaged and set screws removed, fit the

faceplate wrench (Key 3) into the faceplate wrenching hole (Key 2).

6. Turn counter clock-wise to remove the faceplate, turn clock-wise to

install the faceplate.

7. When installing, reverse these steps. TIP The faceplate wrench is not

needed for the assembly. If you over-tighten the set screws you could

damage the threading. Hand tightening is enough.

6.3 Installing/Removing Drive Centre and Live Centre

Warning!

Unplug the machine from power source!

TIP

Do not attempt to remove the live centre with tools, turn the quill until

it pops out.

TIP

The centres pop out quickly, prevent from dropping.

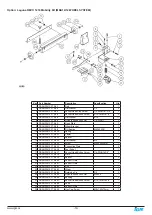

Fig. 12

Fig. 12 - Centre Installation. (1) Knockout rod. (2) Drive Centre. (3)

Quill Hand Wheel. (4) Live Centre.

To install the centres, simply press them into the boring. When the

workpiece is loaded both centres will be pressed into a firm position.

Methods of centre installation vary.

6.4 Removing Drive Centre from Headstock

Tools needed: Knockout rod (PLAREVO1216-1103A).

1. Make sure the lathe is unplugged and cannot be turned on.

2. Lightly grasp the drive centre with free hand prior to step 3 - it will pop

out unexpectedly.

3. Use the knockout rod (Key 1) and lightly tap on the centre.

6.5 Removing Live Centre from Tailstock

Tools needed: none

1. Lightly grasp the live centre with free hand prior to step 2 - it will pop out

unexpectedly.

2. Turning the quill hand wheel (Key 3) counterclockwise will retract quill

and release the live centre from the quill.

6.6 Changing Speed Range

WARNING!

Unplug the machine from power source!

CAUTION!

Pinching hazard. Do no rotate the spindle with hands in the

belt cabinet.

TIP

Do not attempt any other pulley configurations than those described

below.

Fig. 13

Fig. 13: Changing Speed Range. (1) Low Speed Range: 50-525 RPM.

(2) Mid Speed Range: 325-1750 RPM. (3) High Speed Range: 650-3500

RPM. (4) Belt Tension Cam Handle. (5) Drive Pulley. (6) Groove Poly-V

Belt. (7) Driven Pulley.

The lathe has three sets of pulleys for high, medium, and low speed

as described above. The belt should be tensioned so that there is

approximately 3 to 6 mm (1/8 to 1/4“) deflection when the belt is pressed

with moderate thumb pressure. To adjust the amount of tension, see the

Adjustment section. To adjust between the speed ranges, follow these

steps:

Tools needed: none

Unplug the machine from power source!

2. Open both pulley covers to access upper (Key 7) and lower (Key 5)

pulleys.

3. To loosen the belt tension, turn the belt tension cam handle (Key 4)

towards you.

4. Move the drive belt (Key 6) to the required set of pulleys.

5. Tension the belt by returning the belt tension cam handle (Key 4) to its

original position.

6. Test that the belt is set correctly by manually turning the spindle prior to

returning power to the lathe.

7. Machine Operation

7.1 First Use

WARNING!

Read the entire owners manual prior to using this machine.

WARNING!

Never load or adjust the workpiece while the machine is

switched on.

CAUTION!

The workpiece must be balanced to limit vibrations.