-11-

www.igmtools.com

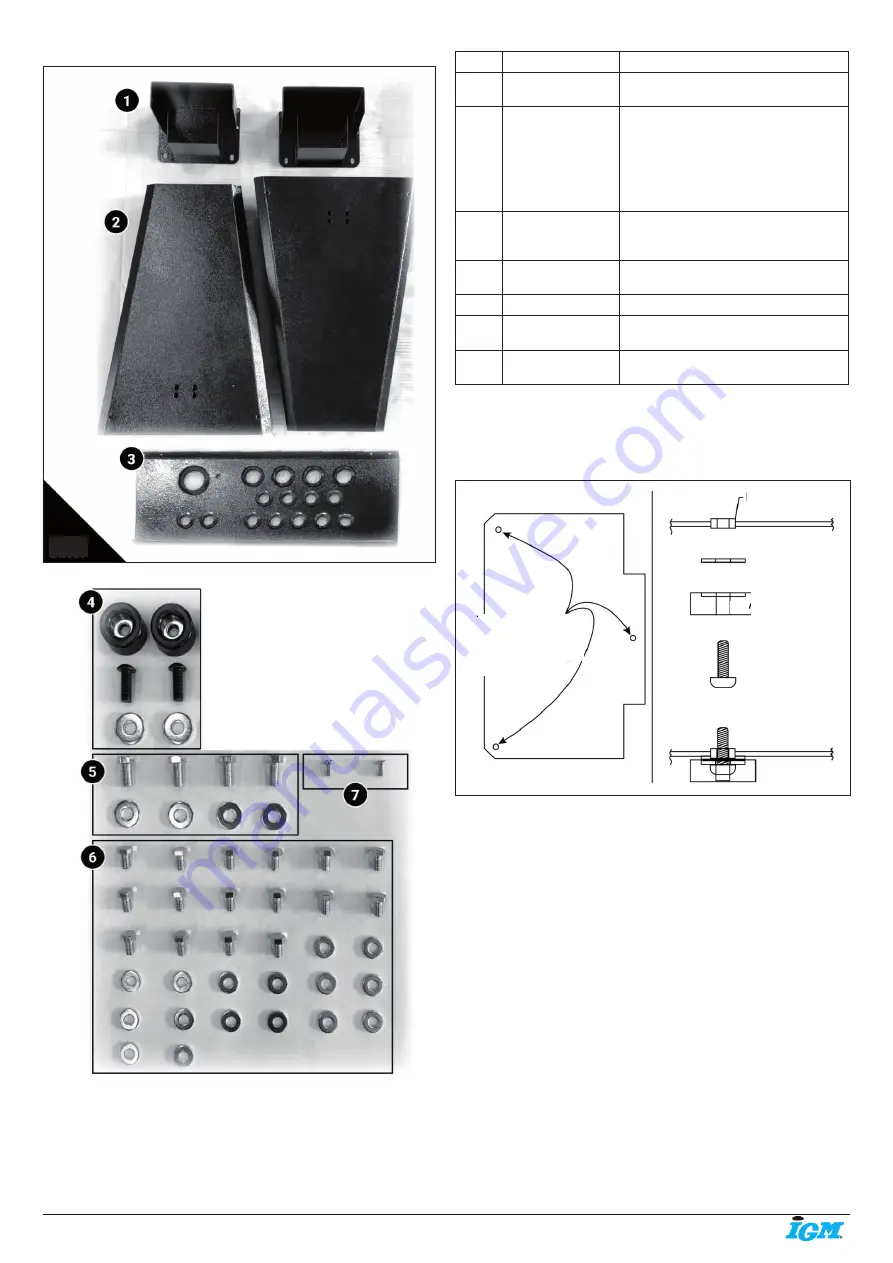

Inventory

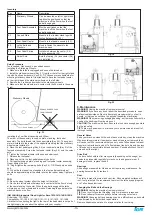

Fig. 25

Fig. 26

Fig. 26: Revo 1216 Adjustable Stand Inventory.

(1) Adjustable height pillars. (2) Stand Leg. (3) Tool Rack. (4) Rubber

pads, screws and washers. (5) Lathe attachment bolts and washers.

(6) Bolts and washers for assembly. (7) Height constraint screws.

Key

Name

Description

1

Height Pillar

PLAREVO1216-204

Main contact point from lathe to stand.

Allows for adjustable height.

2

Stand Leg

PLAREVO1216-201

PLAREVO1216-202

Sheet Steel constructed stand leg. Has

pre-tapped holes to mount.

TECH TIP

These legs are not the same. You will

notice that the bolt holes that connect

the organization shelf are not at the

same height. The lower positioned bolts

holes must be front.

3

Organization Shelf

PLAREVO1216-203

Adds structural stability to stand. Also

holds 13 turning chisels/tools and all

functional set-up tools.

4

Rubber Pads

/Bolts/Washer

Used on the bottom of the stand legs to

minimize vibration.

5

Lathe Bolts/Washer Lathe to stand Fasteners.

6

Assembly

Hardware

Height adjustment fasteners, shelf to leg

fasteners,

7

Height Constraint

Screw

Positions maximum height of

lathe stand.

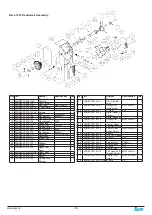

Setup Procedure

1. Make sure the lathe is unplugged and cannot be turned on.

2. Remove the rubber pads from the lathe. This will give 6 rubber pads, 6

hex bolts and 6 washers.

3. Install the rubber pads (Key 4) to the stand legs (Key 2) with Hex

screws and washers.

Fig. 27

4. Identify the left and the right leg. There are four bolt holes on each leg

for the rack (Key 3). The upper two bolt holes must face the rear of the

machine, the lower two bolt holes must face the front of the workspace.

The rack is then installed so that is it angled towards the operator.

5. Identify the correct orientation of the tool rack (Key 3). The lip of the

rack should not be visible. In Fig. 17 the shelf is upside down. A properly

installed rack should have the largest hole (faceplate storage) on the

furthest left and towards the operator.

6. Fasten the stand legs to the tool rack. Use 8 bolts and washers (Key 6).

Tighten all screws at the end of the setup. TIP The stand will not be rigid

until it is fastened to the lathe. Once the lathe is attached and the height is

adjusted properly, it will be very rigid.

7. Install the height pillars (Key 1) to the stand legs with the remaining

eight bolts and washers (Key 6). Tighten all screws at the end of the

setup. TIP Assuming the final height now is easier than later. Nevertheless

it can be positioned later.

8. Carefully reach into the stand leg and install the height constraint screw

on each pillar (Key 7). These screws will prevent the operator from pulling

the lathe out of the stand.

9. Using an additional person, place the lathe onto the stand. Attach the

lathe to the stand. CAUTION! One person must focus on holding the

position of the lathe while the other positions the four bolts and washers

(Key 5).

10. Tighten all bolts.

11. For safety, remove the lathe away from the stand if you would like to

change the height.

12. Avoid over tightening.

Three Rubber

Pads location.

Hex Bolt

Washer

Pre-

Threadings

Rubber Pad (with

pre-installed

washer)