-6-

www.igmtools.com

damage on the bill of lading or refuse the shipment. Immediately call the

dealer store where the machine was purchased.

1. Never accept a shipment that is damaged or partial without notifying the

shipping company and the purchasing store.

5.2 Machine Placement

Prior to removing the machine from the packaging, decide the operating

location of the machine. He dimensions and floor space can be found

here: Dimensions.

1. There should be sufficient area at the front of the machine to allow you

to work on it comfortably.

2. There should be sufficient area at the back of the machine to allow

access for adjustments and maintenance to be conducted.

3. The better the lighting the more accurately and safely you will be able

to work.

4. You should select a solid flat floor, preferably one made of concrete or

similar material.

5. Locate the machine close to a power source and dust collection.

5.3 Unpacking

Once in place, carefully unpack and remove all components. Unpacking

guidelines:

1. Do not cut deep into a box with a blade as it could scratch the paint.

Only cut deep enough to cut the tape or use a dull edge.

2. Organize the hardware and setup tools needed prior to proceeding with

setup.

6. Setting and Adjustment

Setting

WARNING!

Never perform any setup, maintenance or adjustments with

the machine connected to the power source!

WARNING!

If you have any doubt about the described procedure, seek

professional assistance. Do not attempt any procedure that you feel is

unsafe, or that you do not have the physical capability of achieving.

WARNING!

When removing packaging banding, extreme caution must be

used as the banding will spring when cut.

CAUTION!

The machine is heavy. Ensure that you have enough people to

do the job safely.

TIP

There may be sawdust in or around your new machine as a result of

thorough testing.

TIP

Numbers used to describe images are not the same as numbers used

to describe the individual parts in the Parts Section. This is done solely

to help with assembly and give better instructions to those receiving the

machine new. When ordering replacement parts, please only consult the

part numbers and reference images in the Parts Section.

The machine comes as assembled as possible without impacting

shipping costs. With this, there will always be some setup procedures and

adjustments that the craftsman must perform prior to using the machine.

These adjustments and setup procedures are intended to make the

machine work and operate safely.

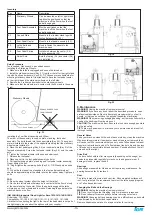

Fig. 10

Fig. 10: Unpacking Revo 1216 Lathe. (1) Unpacking Contents. (2)

Lathe in a box. (3) Components unpacked.

6.1 Installing Rubber Levelling Pads

Rubber pads installed on the lathe reduce vibrations and protect the base

from the floor. Do not install rubber pads if you are planning to use the

stand.

Tools needed: 6mm Hex wrench

1. Make sure the lathe is unplugged and cannot be turned on.

2. Remove the tailstock and banjo (toolrest) from the lathe by releasing

the cam lock and sliding it off the end. NOTICE: You do not need to unbolt

anything to remove banjo or tailstock.

3. CAREFULLY tilt the lathe on its side. Use a blanket or similar soft thing

to cushion the side of the lathe in contact with the floor.

4. Install a washer, rubber pad, and screw on each corner.

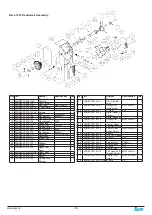

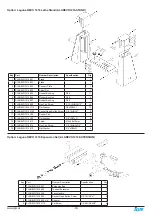

22 Stand

4.2 Internal Description

Fig. 8

1 Front Bearing (Press Fit)

2 Spindle Lock Boring

3 Upper Belt Pulley Steps

4 Rear Bearing (Floating)

5 Indexing Lock

6 Spindle Hand Brake

7 Belt

8 Lower Belt Pulley Steps

9 Belt Tension Lock

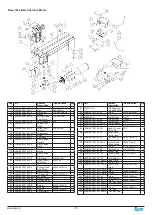

4.3 Inventory

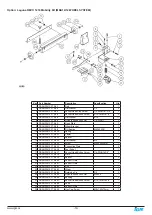

Fig. 9

1. Centre Knockout Rod PLAREVO1216-1103A. Used to release the

headstock centres.

2. Faceplate PLAREVO1216-104A. 76 mm (3“) faceplate used to fasten

workpiece.

3. Faceplate Wrench PLAREVO1836-1136. To release faceplate from

spindle threading.

4. Drive Centre PLAREVO1836-124A. Used in the headstock to turn a

workpiece. No bearing.

5. Live Centre PLAREVO1216-168. Used in the tailstock to keep the

workpiece rotating. Has a bearing.

6. 4x Rubber Foot PLAREVO1216-199. To limit vibrations - Remove if

using a stand.

7. 4x Screw for Rubber Foot PLAREVO1216-1100.

8. 4x Flat Washer PLAREVO1216-198.

5. Transport and Setup

5.1 Receiving

It is likely that your machine will be delivered by a third party. Before

unpacking, be sure to inspect the packaging and shipping documents

supplied by the driver. Ensure that there is no visible damage to the

shipment. If any damage has occurred because of shipment, note the