9

ADJUSTMENT TRANSMITTING ROLLER

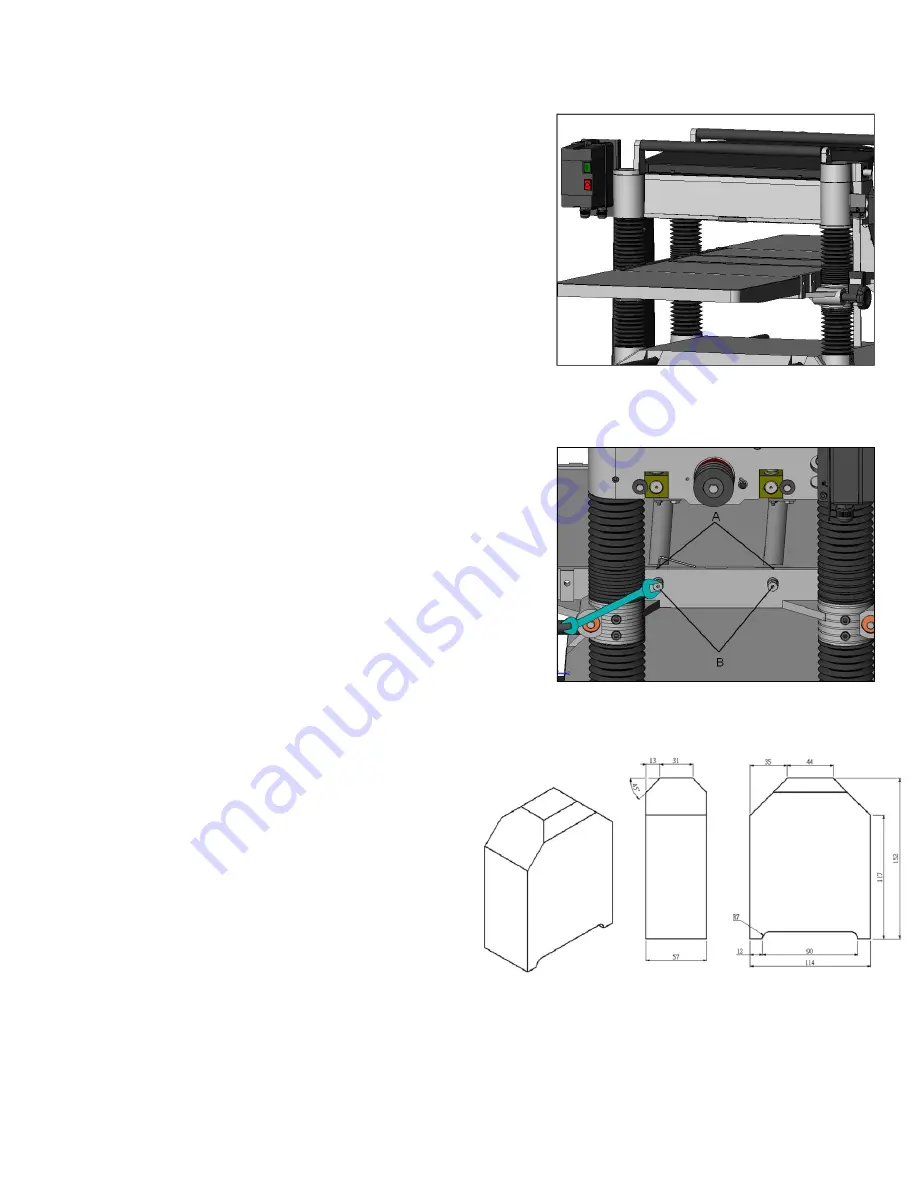

Verify that roller and table are both at the same

height. (Fig.24)

ADJUSTING TABLE ROLLER

To reduce friction between stock and table, two

table roller have been assembled on machine.

Adjustments will be needed when planning with

the different types of wood.

- Roller must be adjusted high, when planning

rough wood.

- Roll must be adjusted low, when planning

smooth wood.

ADJUST ROLLER

- Disconnect machine from power source.

- Place a straight level on table roll, loosen screw

(A) adjust your shaft (B) to the proper height and

tighten back the screw to hold in position. (Fig.25)

Always check to make sure that the front and back

height are the same. There must be no slant

between roller and table.

CONSTRUCTING GAUGE BLOCK

- Before starting any adjustments, disconnect the

machine from the power source.

The manufacturer has adjusted all machines

before delivery.

Verify that the screws are properly tightened.

The only time you will have to adjust your machine

is when it has been functioning for a long time.

The adjustment will have to be made to adjust the

precision of the machine.

Always check the adjustments before starting on a

new project, this will save you time and money. To

check you will need the following supplies.

- Straight scale

- Thickness gauge

- Home made gauge block of hard wood, with the

dimensions as shown in Fig.26

Fig. 24

Fig. 25

Fig. 26