8

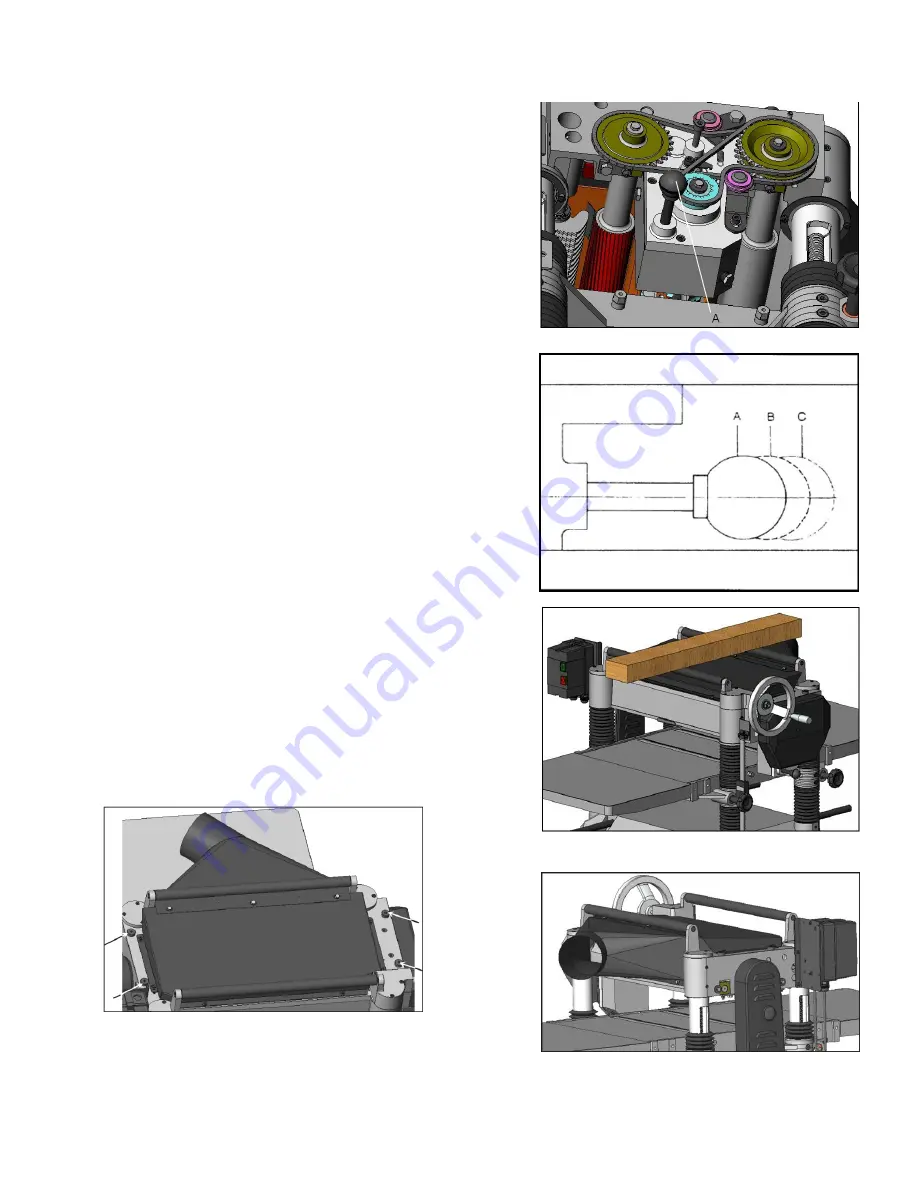

FEED ROLL SPEED RATE

The rate of speed is transmitted by shift gears

located in gear box.

The shift gear handle (Fig.19) performs with three

different methods of speed by using the shift

handle to pull or push.

Fig.20

Position A: feed roll is functioning on 20-FPM

speed rate.

Position B: feed roll is functioning on 0-speed rate.

Position C: feed roll is functioning on 16-FPM

speed rate.

ROLL TRANSMITTING

The purpose of the roll located on top of machine,

is transmitting stock after cutting and shaving

workpieces. This roll will save you lots of time,

and will speed up

you’re working rate. (Fig. 21)

CONNECTING DUST COLLECTOR

Connect dust collector system to hood of machine,

located at the back of machine. The dust collector

will collect all dust and particles while molding in

process, this system will give a clean and safe

working environment. (Fig. 22)

FEEDROLL PRESSURE AJDUSTMENT

The pressure of the feed roll will depend on the

pressure set by the springs, and screws.

To adjust the pressure, you must loosen or tighten

the lever. There are two sets of springs on both

ends of the feed roll,

to ensure great results make sure both sides are at

the same level pressure. (Fig.23)

Fig. 23

Fig. 19

Fig. 20

Fig. 21

Fig. 22