1-61

GENERAL MAINTENANCE

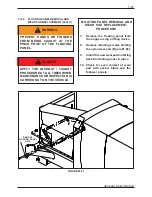

CAUTION

HYDRAULIC TANK

INSPECTION PROCEDURE

1.

Ensure that the parking brake is

applied and the vehicle is tagged

out for maintenance purposes

(refer to the

section 1.5

“Lockout/

Tagout procedure”).

2.

Clean the strainer and replace the

filter element inside the tank after

the first 50 hours of service. Refer

to

section 1.14.8

“Strainer

cleaning procedure”.

3.

Change the return filter element,

twice a year (after the first 50

hours). Refer to section

section 1.14.7

“Filter element

replacement procedure”.

4.

Ensure the proper operation of

the filler cap (Figure #1.83). See

that the filler cap has no

obstruction.

5.

The hydraulic oil must be clean

and not colored as well as in

sufficient quantity (level at 3/4 of

the oil level gage, with all cylinders

retracted).

6.

NOTE: The whole system requires

between 50 to 60 gallons of oil.

MAXIMUM TEMPERATURE FOR

HYDRAULIC OIL IS 180°F.

FIGURE #1.82

OIL GAGE

AND TEMPERATURE

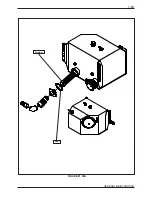

1.14.5

HYDRAULIC TANK INSPECTION

PROCEDURE

Verify that the oil in the reservoir is clean

and always at the appropriate level. The

oil must be clean and not colored.

Содержание Automizer Versa Hand

Страница 2: ...AUTOMIZER VERSA HANDTM 1 2...

Страница 4: ...AUTOMIZER VERSA HANDTM 1 4...

Страница 8: ...AUTOMIZER VERSA HANDTM 1 8...

Страница 43: ...1 43 GENERAL MAINTENANCE FIGURE 1 59 STITCH WELDS FLOOR GUIDES 1 12 7 FLOOR GUIDE REPLACEMENT PROCEDURE Cont d...

Страница 58: ...AUTOMIZER VERSA HANDTM 1 58 FIGURE 1 81 INPUT OUTPUT COVER ELECTRICAL COILS...

Страница 69: ...1 69 GENERAL MAINTENANCE FIGURE 1 89A Strainer Seal...

Страница 77: ...1 77 GENERAL MAINTENANCE A B C BEHIN D D F MAIN RELIEF B E...

Страница 105: ...1 105 GENERAL MAINTENANCE NOTES...