Page 68

LAARS Heating Systems

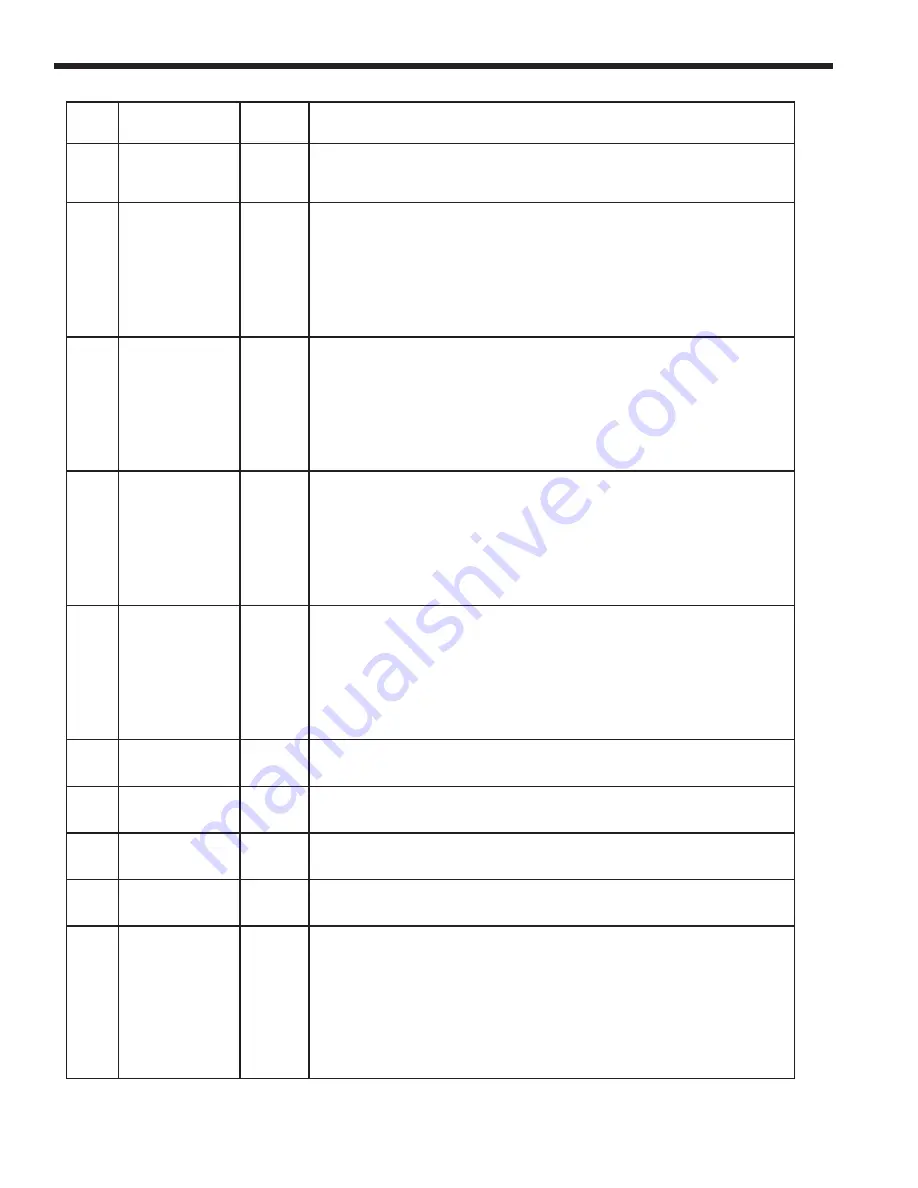

149

Flame detected

H or L

Holds if fl ame detected during Safe Start check up to Flame Establishing

period.

150

Flame not

detected

H

Sequence returns to standby and restarts sequence at the beginning of

Purge after the HF switch opens if fl ame detected during Safe Start check

up to Flame Establishing period.

154

Purge Fan

switch On

H or L 1. Purge fan switch is on when it should be off.

2. Check wiring and correct any errors.

3. Inspect the Purge Fan switch J6 terminal 3 and its connections. Make

sure the switch is working correctly and is not jumpered or welded.

4. Reset and sequence the relay module.

5. If the fault persists, replace the relay module.

155

Purge fan switch

OFF

H or L 1. Purge fan switch is off when it should be on.

2. Check wiring and correct any errors.

3. Inspect the Purge Fan switch J6 terminal 3 and its connections. Make

sure the switch is working correctly and is not jumpered or welded.

4. Reset and sequence the relay module.

5. If the fault persists, replace the relay module.

156

Combustion

pressure and

fl ame ON

H or L

1. Check that fl ame is not present in the combustion chamber. Correct

any errors.

2. Make sure that the fl ame detector is wired to the correct terminal.

3. Make sure the F & G wires are protected from stray noise pickup.

4. Reset and sequence the module, if code reappears, replace the fl ame detector.

5. Reset and sequence the module, if code reappears, replace the module.

157

Combustion

pressure and

fl ame OFF

L

1. Check that fl ame is not present in the combustion chamber. Correct

any errors.

2. Make sure that the fl ame detector is wired to the correct terminal.

3. Make sure the F & G wires are protected from stray noise pickup.

4. Reset and sequence the module, if code reappears, replace the fl ame detector.

5. Reset and sequence the module, if code reappears, replace the module.

158

Main valve ON

L

1. Check Main Valve terminal wiring and correct any errors.

2. Reset and sequence the module. If fault persists, replace the module.

159

Main valve OFF

L

1. Check Main Valve terminal wiring and correct any errors.

2. Reset and sequence the module. If fault persists, replace the module.

160

Ignition ON

L

1. Check Ignition terminal wiring and correct any errors.

2. Reset and sequence the module. If fault persists, replace the module.

161

Ignition OFF

L

1. Check Ignition terminal wiring and correct any errors.

2. Reset and sequence the module. If fault persists, replace the module.

164

Block intake ON

L

1. Check wiring and correct any errors.

2. Inspect the Block Intake Switch to make sure it is working correctly.

3. Reset and sequence the module.

4. During Standby and Purge, measure the voltage across the switch.

Supply voltage should be present. If not, the Block Intake Switch is

defective and needs replacing.

5. If the fault persists, replace the relay module.

Содержание NTV

Страница 4: ...LAARS Heating Systems...

Страница 11: ...Page 7 NEOTHERM Boilers and Water Heaters...

Страница 24: ...Page 20 LAARS Heating Systems Figure 16 Hydronic Piping Single Boiler Zoning with Circulators...

Страница 26: ...Page 22 LAARS Heating Systems Figure 18 Hydronic Piping Multiple Boilers Zoning with Circulators...

Страница 84: ...Page 80 LAARS Heating Systems Parts Illustration 1 Jacket Components...

Страница 86: ...Page 82 LAARS Heating Systems Parts Illustration 4 Internal Components Sizes 750 850...

Страница 88: ...Page 84 LAARS Heating Systems Parts Illustration 6 Gas Train Components Sizes 600 850...

Страница 89: ...Page 85 NEOTHERM Boilers and Water Heaters Parts Illustration 7 Heat Exchanger Components 68A Sizes 285...

Страница 90: ...Page 86 LAARS Heating Systems Parts Illustration 8 Electrical Components Front Battery CR2032 Touchscreen Back...

Страница 91: ...Page 87 NEOTHERM Boilers and Water Heaters Notes...