English

7

GB/5 - FB/80

www.lamarzocco.com

V1.3

4. Operating the Espresso Machine and Preparing Coffee

1) Starting the Espresso Machine

a)

Filling the Boilers with Water

Once the installation procedures have been completed, it is

necessary to fill the boiler tanks with water. Complete the

following procedure to properly fill the boiler tanks:

•

Coffee Boiler

The water flows inside the coffee boiler directly, as soon as

the water system and water filter/softener taps are opened.

Since the inflow of water will compress the air in the boiler it

will be necessary to remove or “bleed” the air from the coffee

boiler. All air must be removed in order to completely “saturate”

the coffee boiler/group assemblies. To remove the air from

the boiler, “bleed the groups”, it will be necessary to remove

the cup tray from the top of the machine. First remove the cup

tray grates from the top of the machine exposing the cup tray.

Remove the screws securing the cup tray and then remove.

Once removed the top of the groups will be exposed.

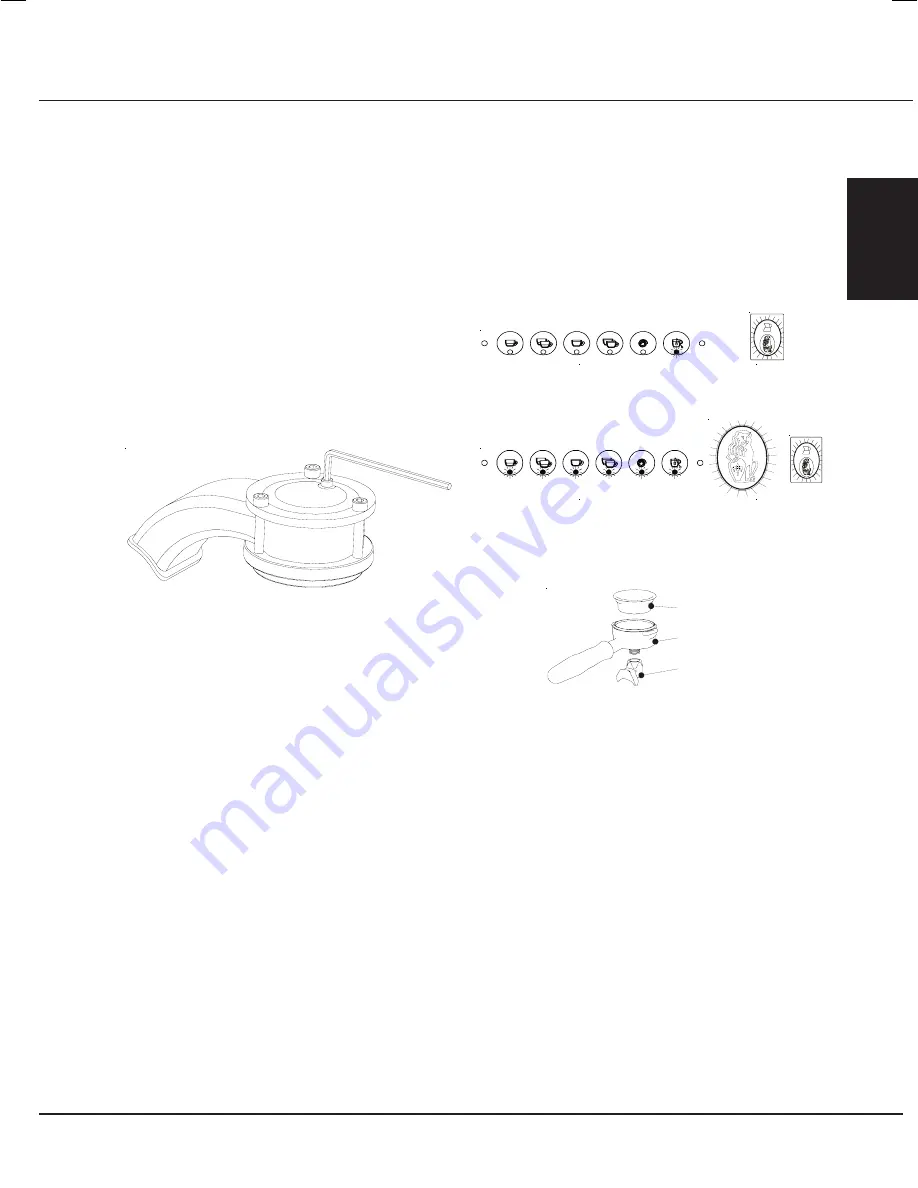

Loosen the bleed screws one at a time (see picture above)

to allow air to escape until water flows from below the screw

head. Tighten the screw to stop the water from flowing. Over

tightening can cause damage to the sealing washer and the

group cover. Repeat this procedure for all groups. Once all

air is removed from the coffee boiler, reinstall the cup tray by

following the removal instructions in reverse.

•

Steam Boiler

Turn the main switch (item 1 in Fig. 1) to position “1” or ON,

the automatic steam boiler level gauge will be switched on,

activating the auto-fill solenoid valve and the motor pump.

This will fill the steam boiler to a predetermined level and will

shut off when full.

Note:

It may happen that the air inside the steam boiler builds up

pressure (which may be detected through the pressure gauge

- item 2, fig. 1) when the water is allowed to flow in; this “false”

pressure must be eliminated by opening the steam valves (item

9, Fig. 1).

b)Turning the Espresso Machine On

Once you have completed these procedures, check the display.

The message “Coffee Boiler Filled?” should be displayed.

Press enter to confirm that the preceding procedures are

complete.

The installation is now complete and the espresso machine

should be heating to the operating temperatures.

2)Waiting for the Espresso Machine to Heat to Operating

Temperature

During this time, it may happen that the pointer of the coffee

boiler pressure gauge reaches as high as 14-15 bar. This may

happen anytime that the heating element is in the on condition.

In this case it is necessary to adjust the expansion valve (Fig. 3)

in such a way that the pressure may never exceed 11-12 bar. In

normal operating conditions, the coffee boiler pressure gauge

can read anywhere from 0-12 bar. When brewing, the pressure

should be set to 9 bar.

When the steam boiler reaches operating temperature, the light

on the Tea dispense button will light.

When the espresso machine is ready to operate all lights on

the keypads will light.

3)Installing the Portafilters

Install the portafilter(s) by inserting them into the group and

rotate the handle from left to right. When the portafilters are

inserted properly, you can press any of brew buttons to start the

flow of water through the portafilter. You should allow hot water

to pass through the portafilter(s) for a few seconds each time,

in order to pre-heat the portafilter.

Note:

It is important to leave the portafilters installed in the espresso

machine when not in use. The portafilter must remain heated

for the brew process to function correctly.

4)Brewing Coffee

It is now possible to remove one of the portafilters to make an

espresso beverage. Place some ground coffee in the filter

itself: 1 dose (approximately 6 g) for the small filter, 2 doses (2

approximately 10-14 g) for the larger filter. Press down on the

ground coffee with the supplied tamper and install the filter

holder up again to the bottom of the group and then press a

button to begin the brewing process.

Note:

Some barista believe it is important to press the brewing button

prior to installing the portafilter to flush any remaining coffee

oils and particles from the group. Some also flush just after

brewing to do the same. Please experiment to make the best

possible procedure for your coffee.

Portafilter

Portafilter

Basket

Portafilter

Spout

EE

AV

EE

AV

Operators Manual - ENG - V 1.3.pmd

30/10/2006, 14.34

7