Common Terms

2-50

KVAL Manual

Validation

All feature groups are analyzed by a validation routine before the software permits the operator to

download the programmed cut to the machines for processing.

The validation routine queries the capabilities of each machine and current tools loaded to deter-

mine if the programmed cuts can be performed by the line. If at least one machine in the line is

capable of performing each cut / feature in the group, the group will be considered valid and the

Add to Queue button will be enabled.

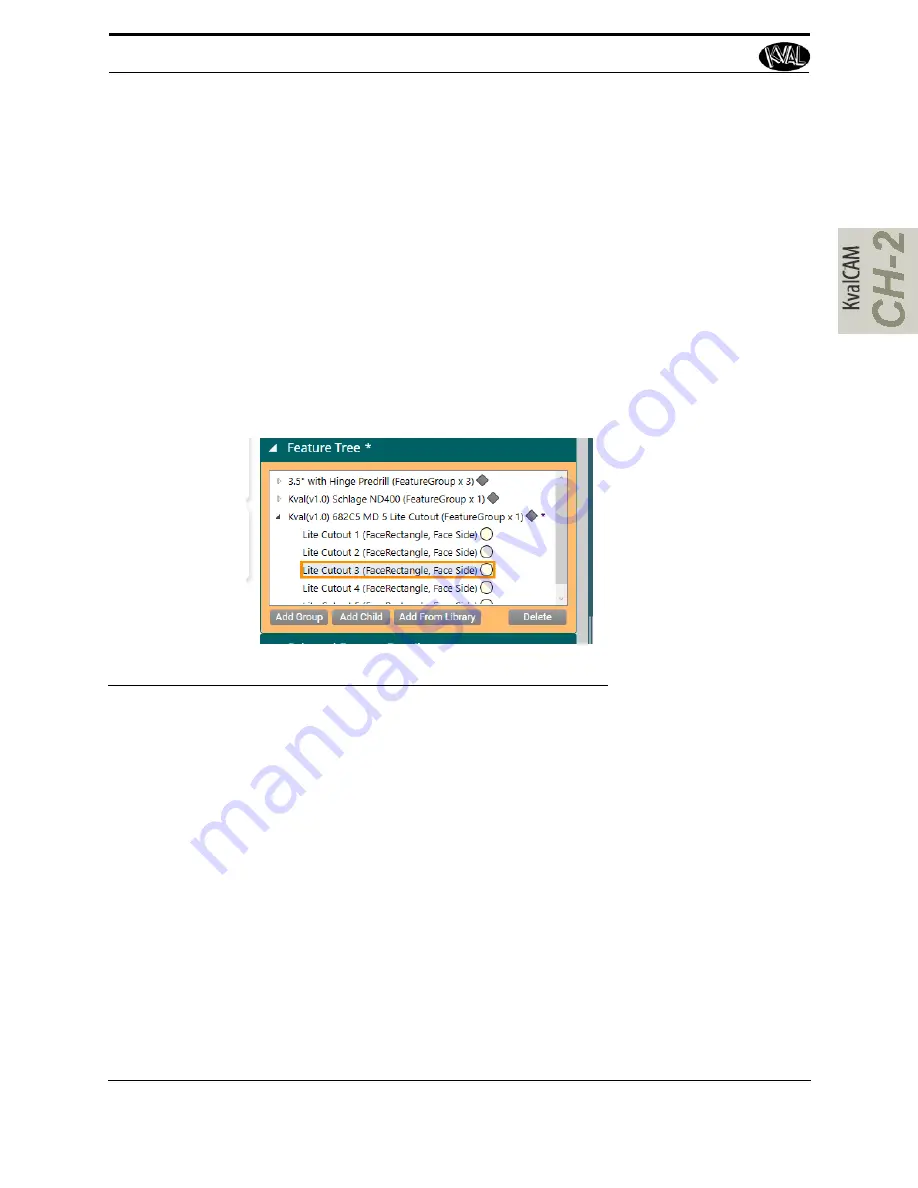

If any feature or cut fails validation, however, a Orange or Red box will be highlighted over the

faulty cut / feature for review and the Add to Queue button will be disabled.

shows a

feature that fails validation.

Note:

Red only appears if the expression cannot be interpreted to a real number for

validation, while orange appears if the line cannot perform the cut.

FIGURE 2- 10.

Example of a Validation Error Indication

Validation Report

A

Validation Report

identifies particular faults that would cause a feature to fail validation. Each

feature has its own validation tests and will fail if the tests for a valid feature are not satisfied.

Clicking on a specific test will provide an explanation of the test being performed so that the user

can correct the mistake.

Validation will only work if the information that is fed to the machine line is accurate. Inaccurate

information that is downloaded from Tool Configurations, Calibrations, or Libraries (e.g. material

types) will produce unexpected or potentially harmful results to the machine and/or operator.

Some cuts in fringe cases may pass validation that result in non-conforming cuts (cut does not

match visual representation).

shows an example of a Variant Report.

Follow the Fail tags and Descriptions to solve error.

Содержание Edge-SS

Страница 4: ...KVAL Edge SS System Operation Manual ...

Страница 6: ...KVAL Edge SS System Operation Manual ...

Страница 12: ...KVAL Edge SS Manual Table of Contents ...

Страница 32: ...How to Download the Service Application KVAL Operation Manual 1 20 Page Intentionally Left Blank ...

Страница 49: ...About Revisions 2 16 KVAL Manual ...

Страница 84: ...Common Terms 2 51 KVAL Manual FIGURE 2 11 Example of a Validation Report ...

Страница 147: ...About the Nodes 5 21 KVAL Operation Manual ...

Страница 149: ...Index Kval Edge SS clean up 12 inspect 12 ...

Страница 150: ......

Страница 151: ......