Replacing Tooling in the Front Section

5-23

KVAL 994-X Operation/Service Manual

2.

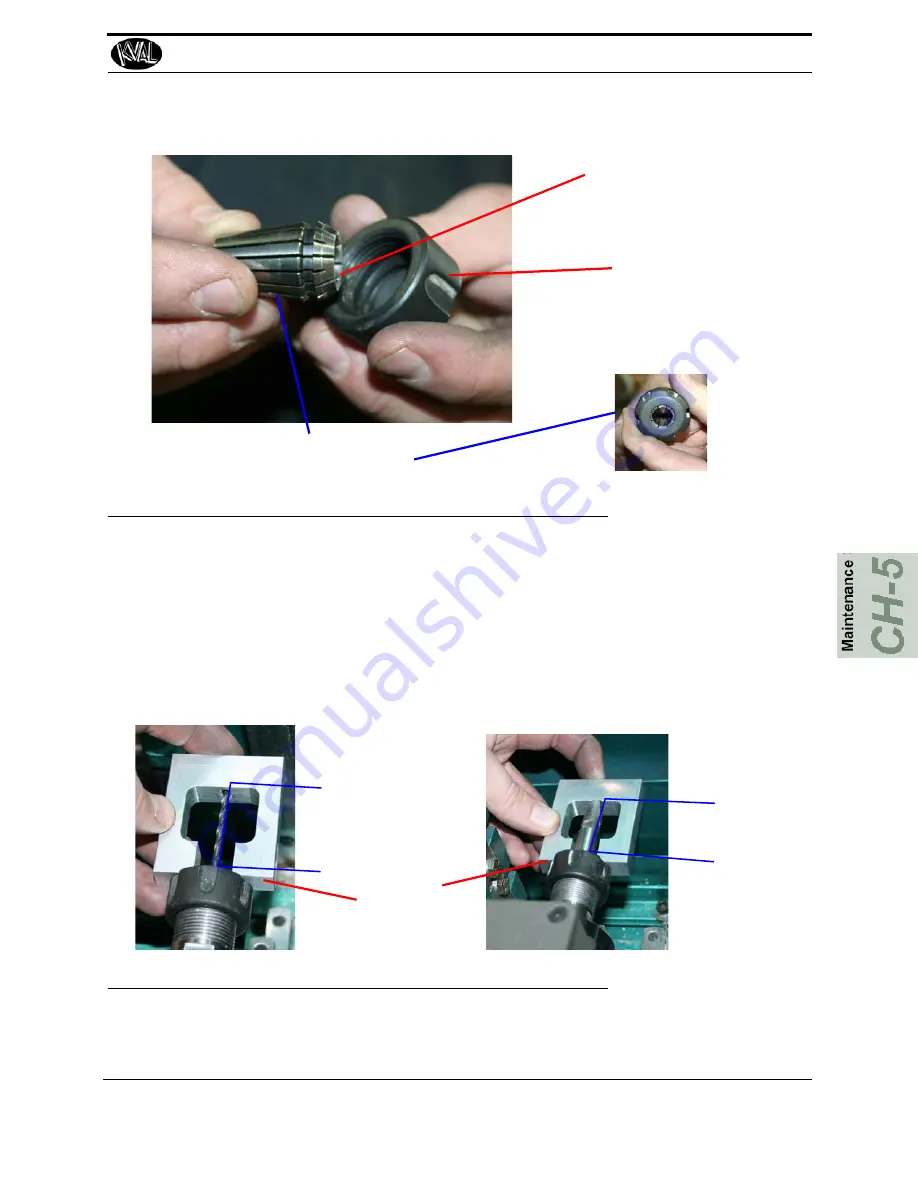

Inspect and clean collet assembly.

Collet Spindle

Collet

Nut

Verify that there is no damage or

bluing on the side of the collet

FIGURE 5. 20.

Collet Assembly

3.

Lightly attach collet assembly on drill.

4.

Insert the new bit into the assembly.

5.

Before tightening the collet assembly, adjust the bit depth. Set the router bit to

1 3/4 “and the drill bit to 2.0” from the base of the collet nut to the tip of the bit. If

available, use Bit Depth Gauge (PN 432 C) to set the depth.

6.

Lightly tighten and torque to correct value. For torque values,

Collet Torque Values

Drill Depth

Set to 2.0”

Router Depth

Set to 1 3/4 “

1 3/4 ““

2.0 “

Bit Depth

Gauge

(PN432C)

FIGURE 5. 21.

Setting the Bit Depths

7.

Tighten the collet assembly.

8.

Inspect and verify the work. Clean the work area.

Содержание 994-X

Страница 4: ...KVAL 994 X Operation Service Manual ...

Страница 29: ...How to Download the Service Application 1 19 KVAL 994 X Operation Service Manual Page Intentionally Left Blank ...

Страница 31: ...Safety Sign Off Sheet 1 21 KVAL 994 X Operation Service Manual ...

Страница 32: ...Safety Sign Off Sheet KVAL 994 X Operation Service Manual 1 22 ...

Страница 88: ...Option SB About the CNC Back Section Operator Screens KVAL 994 X Operation Service Manual 2 56 ...

Страница 110: ...Calibration of the Back Section KVAL 994 X Operation Service Manual 3 22 ...

Страница 114: ...System IT Administration KVAL 994 X Operation Service Manual 4 4 ...

Страница 144: ...Collet Torque Values KVAL 994 X Operation Service Manual 5 30 ...

Страница 180: ...Symptoms and Possible Causes KVAL 994 X Operation Service Manual 6 36 ...

Страница 185: ......

Страница 186: ......

Страница 187: ......