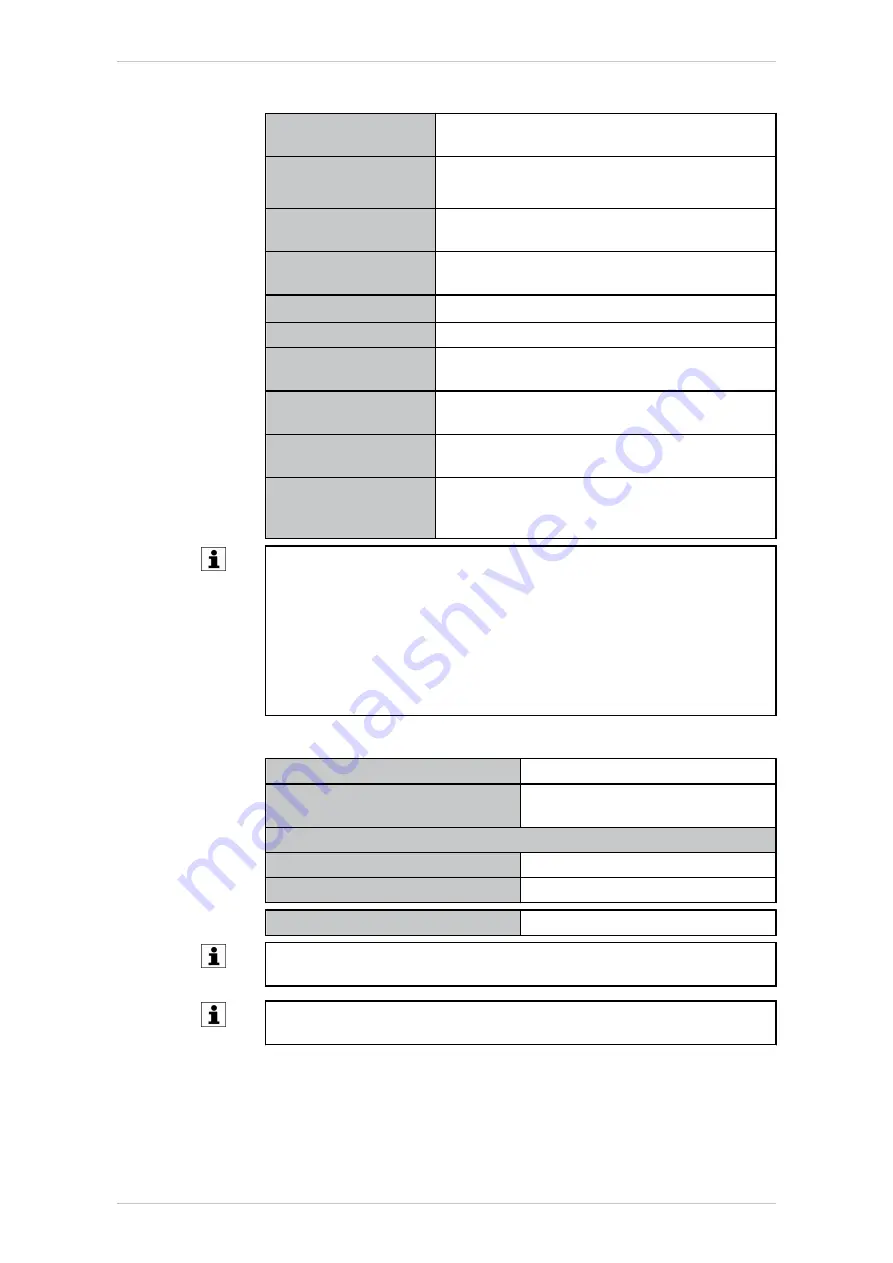

Foundry robots

Overpressure in the

arm

0.03 MPa (0.3 bar) ±10%

Compressed air

Free of oil and water

in accordance with ISO 8573-1:2010 (7:4:4)

Compressed air sup-

ply line

Air line in the cable set

Operating pressure

(PURGE)

max. 0.03 MPa (0.3 bar) ±10%

Air consumption

0.1 m

3

/h

Air line connection

Push-in fitting for hose, 6 mm

Thermal load of the

wrist

10 s/min at 180 °C (453 K)

Resistance

Increased resistance to dust, lubricants, cool-

ants and water vapor.

Special paint finish on

the robot

Special paint finish on the entire robot, and an

additional protective clear coat.

Other ambient condi-

tions

KUKA Deutschland GmbH must be consulted if

the robot is to be used under other ambient

conditions.

The manipulator is designed in such a way that, in accordance with

standard IEC 60529, no water can penetrate into electrical equipment

spaces in normal operation. Water spray and corrosive additives can

nevertheless lead to corrosion (rust) on uncoated parts. In this case, it

is advisable to provide the equipment with corrosion protection. Corro-

sion does not represent a defect as defined by the standard, as long as

it does not have a detrimental effect on the protection rating. The pro-

tection rating is valid in the case of compliance with the specified ambi-

ent conditions.

Ambient conditions

Humidity class (EN 60204)

-

Classification of environmental

conditions (EN 60721-3-3)

-

Ambient temperature

During operation

0 °C to 55 °C (273 K to 328 K)

During storage/transportation

-40 °C to 60 °C (233 K to 333 K)

pH value

7.0 to 9.0

For operation at low temperatures, it may be necessary to warm up the

robot.

During operation in the low-temperature range, frost and condensation

must be avoided, as damage to property may otherwise arise.

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021

www.kuka.com

| 87/344

Technical

data

Содержание IONTEC KR 20 R3100

Страница 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Страница 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Страница 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Страница 300: ...Fig 9 58 Wiring diagram axis A2_KS A1 A3 KR IONTEC 300 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 301: ...Fig 9 59 Wiring diagram axis A3_KS A1 A3 KR IONTEC MA KR IONTEC V4 Issued 11 05 2021 www kuka com 301 344 Repair...

Страница 302: ...Fig 9 60 Wiring diagram axis A4_KS A1 A3 KR IONTEC 302 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 303: ...Fig 9 61 Wiring diagram axis A5_KS A1 A3 KR IONTEC MA KR IONTEC V4 Issued 11 05 2021 www kuka com 303 344 Repair...

Страница 304: ...Fig 9 62 Wiring diagram axis A6_KS A1 A3 KR IONTEC 304 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 318: ...KR IONTEC 318 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Decommissioning storage and disposal...

Страница 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...