8

Maintenance

Only maintenance and repair work described in this document may be

performed.

Work that exceeds this scope may only be carried out by personnel spe-

cially trained by KUKA. Information about KUKA College and its training

program can be found at www.kuka.com or can be obtained directly from

our subsidiaries.

In the case of support and repair services provided by KUKA, KUKA Serv-

ice must be informed in advance about potential contamination or haz-

ards.

Non-compliance nullifies warranty and liability claims.

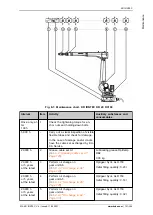

8.1

Maintenance overview

Description

The maintenance intervals given in the tables are valid for the operating

conditions specified in the technical data (

>>>

). KUKA Deutschland must be consulted in the event of

deviations in working conditions or the use of special functions or applica-

tions.

Further information can be found in the section “Information for plan-

ning” (

>>>

5.1 "Information for planning" Page 159

A general inspection of the manipulator is recommended after 7 years or

upon modifying its use. Please contact KUKA Service for this.

If the robot is fitted with a KUKA energy supply system (optional), addi-

tional maintenance work must be carried out.

NOTICE

Only auxiliary substances and consumables approved by KUKA

Deutschland GmbH may be used. Non-approved auxiliary substances

and consumables may cause premature wear and failure of assemblies.

Precondition

• The maintenance points must be freely accessible.

• Remove the tools and any additional items of equipment if they im-

pede maintenance work.

WARNING

Danger to life and limb due to unintended robot motions

When carrying out the following work, the robot must be moved several

times between the individual work steps. Unintended robot motions may

result in death, severe injuries or damage to property.

• While work is being carried out on the robot, it must always be se-

cured by activating the EMERGENCY STOP device.

• If work is carried out on an operational robot that is switched on, the

robot must only be moved at reduced velocity. It must be possible to

stop the robot at any time by activating an EMERGENCY STOP de-

vice. Operation must be limited to what is absolutely necessary.

• Warn all persons concerned before switching on and moving the ro-

bot.

KR IONTEC

MA KR IONTEC V4 | Issued: 11.05.2021

www.kuka.com

| 189/344

Maintenance

Содержание IONTEC KR 20 R3100

Страница 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Страница 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Страница 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Страница 300: ...Fig 9 58 Wiring diagram axis A2_KS A1 A3 KR IONTEC 300 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 301: ...Fig 9 59 Wiring diagram axis A3_KS A1 A3 KR IONTEC MA KR IONTEC V4 Issued 11 05 2021 www kuka com 301 344 Repair...

Страница 302: ...Fig 9 60 Wiring diagram axis A4_KS A1 A3 KR IONTEC 302 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 303: ...Fig 9 61 Wiring diagram axis A5_KS A1 A3 KR IONTEC MA KR IONTEC V4 Issued 11 05 2021 www kuka com 303 344 Repair...

Страница 304: ...Fig 9 62 Wiring diagram axis A6_KS A1 A3 KR IONTEC 304 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 318: ...KR IONTEC 318 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Decommissioning storage and disposal...

Страница 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...