• Start up the robot system in accordance with the chapter “Start-up and

recommissioning” in the operating instructions for the robot controller.

• Put the robot system into operation in accordance with the chapter

“Start-up and recommissioning” of the operating and programming in-

structions for the KUKA System Software (KSS).

7.3

Starting up robots (machine frame mounting)

Description

The machine frame mounting assembly is used for installing robots on a

steel structure prepared by the customer, on a carriage of a linear unit, or

on an adapter plate.

8 hexagon bolts with conical spring washers are used for fastening the ro-

bot to a machine frame. A cylindrical pin and a flat-sided pin are provided

to ensure correct positioning.

This description is valid for the installation of floor, wall and ceiling-moun-

ted robots with the mounting variant “machine frame mounting”.

The robot must be rotated for wall and ceiling mounting. In doing so, it

must be secured such that an uncontrolled rotational motion or toppling is

impossible; the center of gravity must be taken into account

(

>>>

6.1 "Transporting the robot" Page 167

). When rotating the robot,

care must be taken not to damage the connectors, installation material

and/or energy supply system (optional). The wall-mounted or ceiling-moun-

ted installation is analogous to installation of the floor-mounted robot.

NOTICE

If a fixture is used, the manipulator must be secured in such a way that

slipping is impossible. Only approved fixtures with an adequate carrying

capacity may be used. Damage to property may otherwise result.

The installation and start-up of the robot controller, the tools mounted and

the applications are not described here.

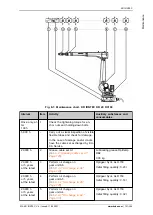

Equipment

The following equipment is required:

Designation

Article number

Lifting tackle/rope sling with sufficient

load-bearing capacity and suitable lifting

accessory

-

Fork lift truck or crane with adequate car-

rying capacity

-

LLA forklift slot KR IONTEC

0000-339-419

Set of Allen keys

1.5; 2; 2.5; 3; 4; 5; 6; 8; 10 mm

-

Torque wrench

min. 2 to 20 Nm

-

Torque wrench

min. 300 to 500 Nm

-

Material

The following material is required:

KR IONTEC

178/344 |

www.kuka.com

MA KR IONTEC V4 | Issued: 11.05.2021

Start-up

and

recommissioning

Содержание IONTEC KR 20 R3100

Страница 14: ...KR IONTEC 14 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Introduction...

Страница 166: ...KR IONTEC 166 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Planning...

Страница 188: ...KR IONTEC 188 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Start up and recommissioning...

Страница 300: ...Fig 9 58 Wiring diagram axis A2_KS A1 A3 KR IONTEC 300 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 301: ...Fig 9 59 Wiring diagram axis A3_KS A1 A3 KR IONTEC MA KR IONTEC V4 Issued 11 05 2021 www kuka com 301 344 Repair...

Страница 302: ...Fig 9 60 Wiring diagram axis A4_KS A1 A3 KR IONTEC 302 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 303: ...Fig 9 61 Wiring diagram axis A5_KS A1 A3 KR IONTEC MA KR IONTEC V4 Issued 11 05 2021 www kuka com 303 344 Repair...

Страница 304: ...Fig 9 62 Wiring diagram axis A6_KS A1 A3 KR IONTEC 304 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 310: ...KR IONTEC 310 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Repair...

Страница 318: ...KR IONTEC 318 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 Decommissioning storage and disposal...

Страница 340: ...KR IONTEC 340 344 www kuka com MA KR IONTEC V4 Issued 11 05 2021 KUKA Service...