(A) New blade

(B) Worn blade

(C) Cracked blade

Replacing

IMPORTANT :

• Use the proper metric size box or socket

wrench to tighten or loosen the blade mounting

bolt.

1. Tilt up the mower deck.

(See TILTING UP THE MACHINE on page 53.)

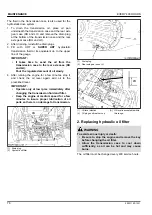

2.

RCK60P

,

RCK72P

Wedge a block of wood between the blade and the

mower housing or use a box wrench over the pulley

nut to prevent the spindle from rotating while

removing the blade bolts. Then, loosen the blade

bolt as illustrated.

RCK60R

,

RCK72R

Set the pipe between the blade and the next blade

or use a box wrench over the pulley nut to prevent

the spindle from rotating while removing the blade

bolts; loosen the blade bolt as illustrated.

RCK60P, RCK72P

(1) Block

(A) “LOOSEN”

RCK60R, RCK72R

(1) Pipe

(A) “LOOSEN”

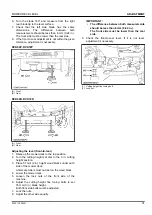

3. To sharpen the blades yourself, clamp the blade

securely in a vise.

Use a large mill file and file along the original bevel

until sharp.

4. To check the blade for balance, place a small rod

through the center hole. If the blade is not

balanced, file the heavy side of the blade until

balance is achieved.

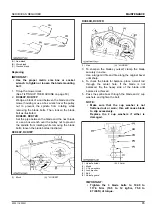

5. Pass the spline boss through the blade and 2 cup

washers, and tighten the bolt.

NOTE :

• Make sure that the cup washer is not

flattened out or worn; this will cause blade

to slip excessively.

Replace the 2 cup washers if either is

damaged.

(1) Spindle holder

(2) Blade

(3) 2-Cup washers

(4) Lock washer

(5) Bolt

(6) Spindle guard

(A) 30 mm

IMPORTANT :

• Tighten the 3 blade bolts to 102.9 to

117.6 N

⋅

m (10.5 to 12 kgf

⋅

m, 75.9 to

87 lbf

⋅

ft) of torque.

SERVICE AS REQUIRED

MAINTENANCE

ZD1211,ZD1221

85

Содержание ZD1211-60

Страница 15: ...SAFETY LABELS SAFE OPERATION 12 ZD1211 ZD1221 ...

Страница 16: ...SAFE OPERATION ZD1211 ZD1221 13 ...

Страница 17: ...SAFE OPERATION 14 ZD1211 ZD1221 ...

Страница 18: ...SAFE OPERATION ZD1211 ZD1221 15 ...