KTR-STOP

®

M-A-F B-xx

Operating/Assembly instructions

KTR-N

Sheet:

Edition:

445145 EN

16 of 23

1

Please observe protection

note ISO 16016.

Drawn:

2022-12-20 Ka/Wie

Replacing:

Verified:

2022-12-21 Ka

Replaced by:

Viscosity

We would recommend a viscosity range from 20 to 220 mm

2

/s (cSt) of the hydraulic liquid with operating tempera-

ture. The viscosity during starting should not exceed 500 mm

2

/s and the viscosity during operation should not fall

below 12 mm

2

/s.

Filtration

When filling and re-filling the hydraulic system and replacing the hydraulic liquid, the oil needs to be filtered. For

that purpose use an offline filter or a respective fill unit. In addition we would recommend to use an inline filter.

The service life of the brake system is extended depending on the degree of purity of the oil.

As a standard the KTR basic power packs are equipped with a 10 µm inline filter.

In order to ensure the reliability of the system, only those oils originating from the following purity classes are

permitted:

•

ISO 4406, class 18/16/13

Maintenance operations on the hydraulic system

In order to ensure a smooth operation of the overall system, the maintenance operations on the hydraulic system

(inspection of level and degree of dirt, replacing the hydraulic liquid resp. filter elements, etc.) have to be perfor-

med as per the manufacturer's operating instructions.

The system has to be flushed resp. vented after each replacement of the hydraulic liquid.

!

Adverse reactions may be generated by mixing different liquids or liquids of various manu-

facturers.

Please contact the manufacturer of mineral oils if you intend to replace the hydraulic liquid.

!

Make sure that the entire brake/hydraulic system is depressurized.

S T O P

Parts released or falling down may cause injury to persons or damage on the machine.

Secure the components before disassembly.

If a sensor is used (component 8) it has to be removed before the brake is disassembled.

•

Drain the hydraulic oil completely from the brake.

•

Dispose of the hydraulic oil as per chapter 4.12.

•

Disconnect the leakage oil and pressure oil line from the brake.

•

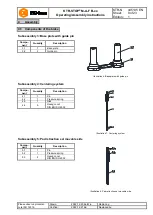

Remove the 2-off screws serving for fixing the brake to the connection plate.

•

Take out the brake.

4

Assembly

4.9 Recommendation of fluids to be used

4.10 Disassembly of the brake