FS-107

2-9

1

O

UTLINE

2

UNIT EXPLANA

TION

3

DIS./ASSEMBL

Y

[3]

Paper alignment control

PS709

5VDC

PS709

SGND

PS702

5VDC

PS702

SGND

PS710

5VDC

PS710

SGND

FS CB

M703

24VDC

24VDC

M703 OUT A

M703 OUT A

M703 OUT B

M703 OUT B

M702

24VDC

24VDC

M702 OUT A

M702 OUT A

M702 OUT B

M702 OUT B

M704

24VDC

24VDC

M704 OUT A

M704 OUT A

M704 OUT B

M704 OUT B

24VDC

24VDC

24VDC

5VDC

5VDC

SGND

SGND

PGND

PGND

PGND

SGND

SGND

M ACK

SGND

S REQ

M RXD

SGND

S ACK

M REQ

SGND

M TXD

MAIN BODY

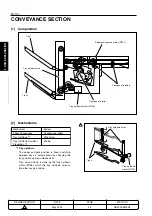

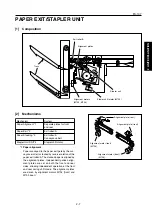

During sorting and stapling, paper exited by the

conveyance section is sent to the alignment section by the

M702 (paper exit motor) reverse direction, then aligned by

the alignment plates driven by the M703 (alignment motor,

(rear)) and the M704 (alignment motor, (front)).

The home position of the alignment plates is detected by

the PS709 (alignment plate detect PS (rear)) and the

PS710 (alignment plate detect PS (front)). The FS CB (FS

control board) controls the M702, M703 and M704. The

related signal are passed to the PS702 (paper entrance

detect PS).

1.

Operations

a.

Normal alignment operation

The front and rear alignment plates work in symmetry

to the front and rear based on the center of the

alignment section, alternately aligning and releasing.

To create this symmetrical movement the M703 and

M704 always rotate in opposite directions.

Every five sheets of the conveyed paper are aligned

and sent on to the paper exit section.

The timing of the M703 and M704 are set to the

starting point by the ON/OFF of the PS702 (paper

entrance detect PS).

b.

Offset (shift alignment) operation

The sheets corresponding to odd sets of copies are fed

to the paper exit unit as soon as they have been aligned

normally. (up to 5 sheets are stacked and exited.)

During the alignment operation for even sets of

copies, M703 and M704 rotate in the same direction,

shifting the sheets forward from the center. The

aligned sheets are then sent to the paper exist

unit.(up to 5 sheets are stacked and exited.)

c.

Staple mode operation

In the staple mode, the M703 and M704 are released

after the stapling action is completed.

The ON/OFF timing of the M703 and M704 is set as

the M702 is turned from OFF to ON, and the PS702 is

turned OFF after the specified period of time.

1

METHOD

REPLACEMENT

PAGE

2-9

DATE

May 2000

REVISED EDITION

1

Содержание FS-107

Страница 1: ...KONICA CORPORATION TECHNOLOGY SUPPORT CENTER TOKYO JAPAN SERVICE HANDBOOK FS 107 2001 02 Ver 3 0...

Страница 2: ...CN26NF1780 KONICA CORPORATION COPYRIGHT 2001...

Страница 4: ...Blank page 2 1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY...

Страница 5: ...1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY OUTLINE 1...

Страница 6: ...Blank page 2 1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY...

Страница 14: ...Blank page 2 1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY...

Страница 15: ...1 1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY UNIT EXPLANATION 2...

Страница 16: ...Blank page 2 1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY...

Страница 32: ...Blank page 2 1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY...

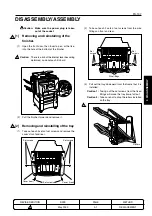

Страница 33: ...1 OUTLINE 2 UNIT EXPLANATION 3 DIS ASSEMBLY DISASSEMBLY ASSEMBLY 3...