34

Piping Instructions

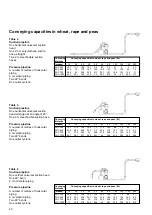

The capacity of the blower depends

to a large extent on the arrange-

ment of the pipe layaut.

The following points should be

observed:

1. Clean-up operations:

Connect the two flexible steel

hoses or a 45º bend and a steel

hose to suction cyclone and

use the hoses to bring the suc-

tion line uniformly down to the

ground. Then extend it with rigid

pipes and use the flexible poly-

hose just before the intake

nozzle.

2. Suction from a hopper:

Use the short suction line of

flexible steel hose only. The

highest capacity is obtained if

the intake nozzle is placed as

vertically as possible.

45° bend

Note:

The poly-hose is designed

for clean-up only. For prolonged

operations of the blower use the

heavy duty flexible steel hoses and

pipes only.

Use only one poly-hose in the

suction line. More poly-hoses will

reduce the conveying capacity

considerably.

Avoid connecting the poly-hose

directly to the suction cyclone. This

puts too much stress on the hose

and may cause a sharp bend

reducing capacity.

3. Keep the pipeline as short as

possible. Do not use more

bends and diverters than

6. If possible, all pipes should run

either horizontally or vertically.

Sloping pipes reduce capacity

and increase pipe wear.

7. Pipelines can be suspended in

long free spans but do not allow

these to exceed 4 m outdoors

and 5 m indoors without sup

-

port.

8.

Especially for SUC 1000:

Do

always use the sturdy OKR

clamps on both suction and

pressure side. Do always use

the reinforced OKR pipes on the

suction side of the blower.

necessary. This provides opti-

mum capacity and the gentlest

conveying.

4. Always use the OK160 dimen

-

sions for the entire pipe system.

Even a short piece of either

bigger or smaller diameter will

reduce conveying capacity con-

siderably.

5. Air leaks between pipes will

reduce conveying capacity. This

is more important on the suction

line than on the pressure line.

Therefore, take care to avoid

leaks on suction line. It should

be recommended to use the

sturdy OKR clamps on the

suction side.