41

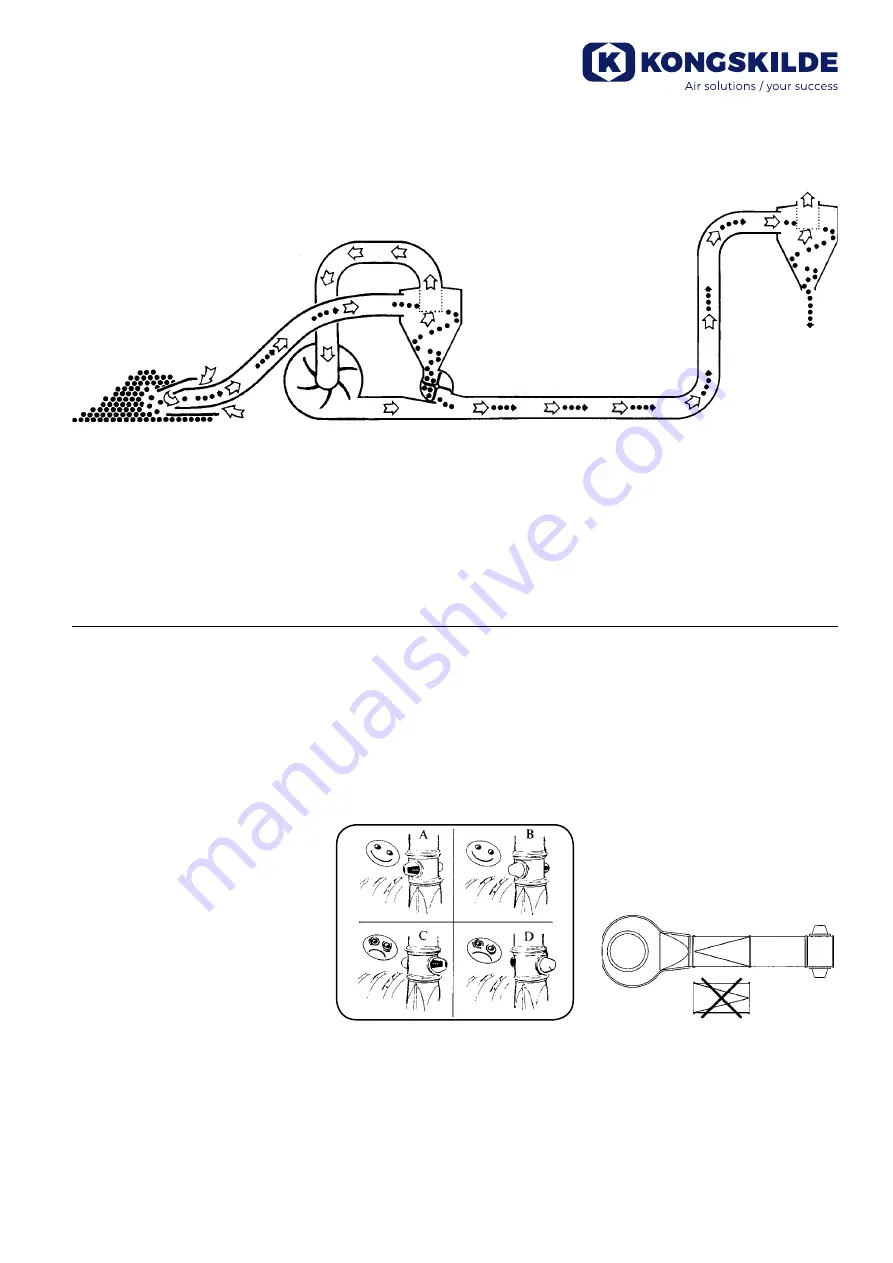

The blower is provided with an

automatic air regulator positioned in

the pipe between the cyclone and

the blower intake.

The purpose of the air regulator

is to limit the max. air speed to

the ideal conveying speed of

approximately 25 m/sec. Thus grain

damage owing to excessive speed

as well as overloading of blower will

be avoided.

The air regulator is plumbed from

the factory, and the adjustment may

not be changed.

The air regulator for

SUC500/700/1000 should always

face as shown in fig. A or B,

otherwise the conveying capacity

would be reduced.

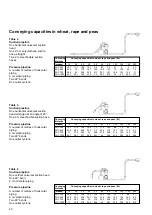

Principle of Operation

Intake nozzle

Suction side

Suction

cyclone

Blower

Rotary valve

Pressure side

Discharge cyclone

The suction blower consists of a

powerful blower and a rotary valve.

Conveying is started by using the

suction air of the blower to lift and

accelerate the grain towards the

blower.

Just before the grain reaches the

blower housing it is separated from

this air stream in a cyclone and

dropped into the rotary valve. The

rotary valve conveys the grain from

the suction side in the cyclone to

the pressure side in the transport

pipe.

Grain is carried to the outlet

cyclone in an air stream. The outlet

cyclone stops the grain, before

it comes out of the outlet in the

bottom of the cyclone. The air is

blown out through the top of the

cyclone.

Especially for SUC 1000 TR

The filter in the suction cyclone of the

SUC 1000 TR is with open bottom.

In order to avoid grain being sucked

into the blower by an accident, safety

filter is mounted in the pipeline between

the cyclone and the blower. The filter

must always be placed as shown on

the filter.

The filter will normally only start working

if the cyclone, by an accident, is

overfilled. This may occur, if the rotary

valve stops due to a broken V-belt, or if

the exhaust cyclone is blocked.

Function of air regulator

Safety filter